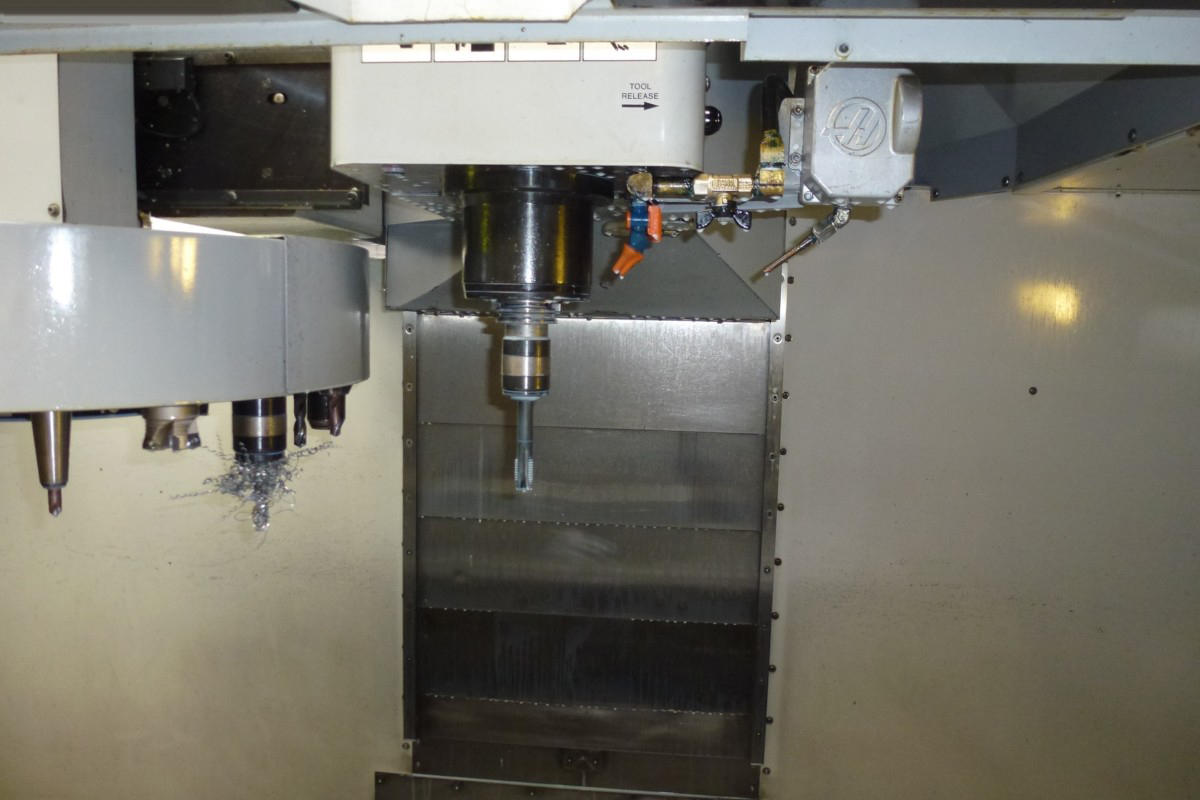

Used HAAS VF-3 #9112944 for sale

URL successfully copied!

Tap to zoom

ID: 9112944

Vintage: 2009

Vertical machining center

Spindle hours: 4,000

Operating hours: 8,000

Table size: 1219 mm X 457 mm

Turning speeds: 8100 U/min

Tool taper: SK 40

2009 vintage.

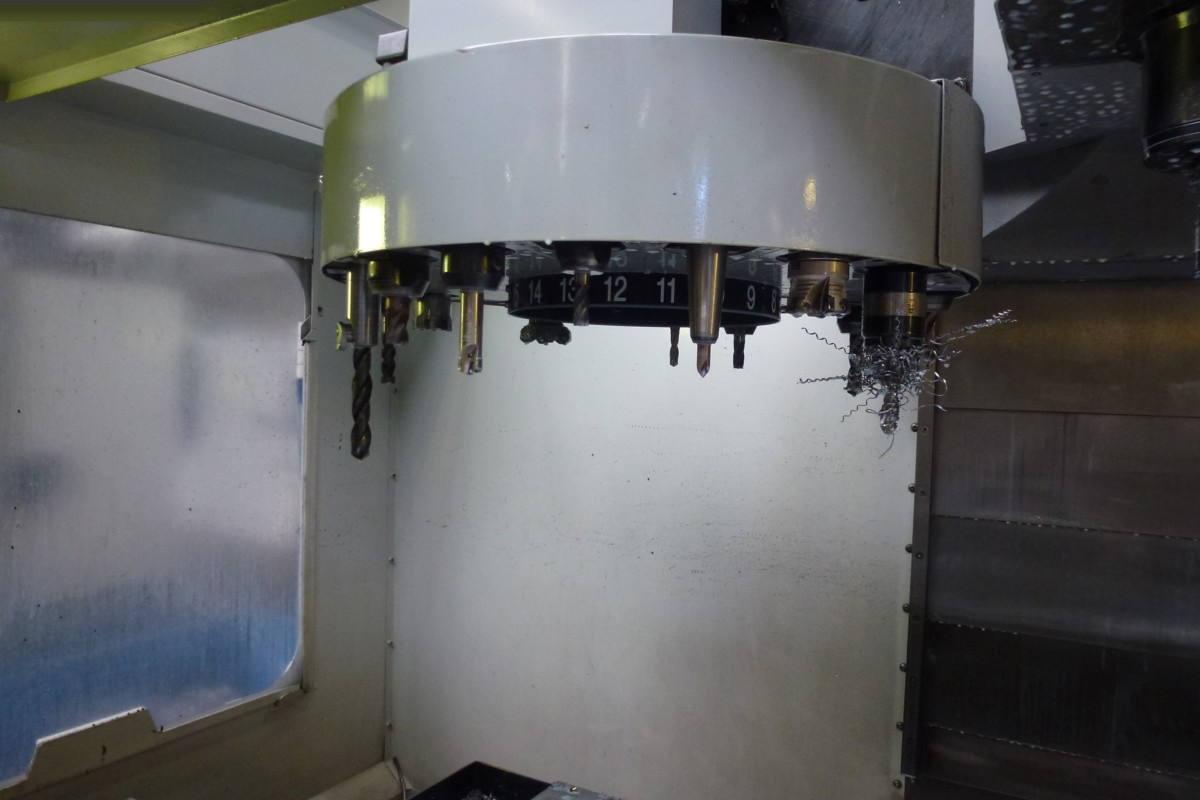

HAAS VF-3 is a 5-axis, vertical machining center designed to provide precision and accuracy in a variety of machining applications. It is an ideal machine for drilling, tapping, milling, and boring operations as well as secondary operations such as drilling, chamfering, contouring, and grooving. With the option of high-speed, high-bandwidth spindle and feed rate options, this machine can accommodate a wide range of tools and materials. This machine features a heavy-duty, cast-iron bed and column construction which provide exceptional rigidity and stability at high cutting speeds. The overhead arm is constructed from Meehanite iron for strength and scaled on both axes with integral dowel pins for repeatability. This machine also features a 40" x 20" full-envelope working envelope and an extended reach between the spindle nose and stump for workpieces up to 24" tall. HAAS VF 3 features two 4000-RPM spindle speeds with a direct-drive system and an optional high-speed spindle. It also features an electro motion controlled servo motor, allowing for a wide range of cutting, drilling, and tapping tools. The CNC control offers a fully automatic, 2-way spindle and rapid traverse commands and a programmable backlash eliminator. It also includes a series of fully automated electronic sub-programs, such as parameter reset, radius compensation, constant surface speed, and tool and fixture touch-off. VF-3 is capable of controlling up to ten programmable axes. It also features a 12" Color LCD touch screen and electronic handwheel to make programming easy and intuitive. The programmable memory capacity of 1GB RAM allows for large programs and part files. It also includes tool breakage and crash detection capabilities, helping to improve machine performance and accuracy. The machine comes preconfigured with a 1000 PSI coolant system and is capable of producing a clean surface finish of 64 RA (unpolished). It also includes an integrated dynamic workholding system and over 200 built-in tool settings, which enable users to quickly adjust to the changing needs of their machining projects. Overall, VF 3 is an incredibly versatile and powerful machine tool. It offers an impressive combination of speed, accuracy, and reliability and can accommodate a wide range of machining operations and materials. Its technologically advanced design and construction also provides users with the assurance that it can stand up to a variety of demanding manufacturing tasks and maintain a high level of precision and performance throughout its life.

There are no reviews yet