Used HAAS VF-4 #9006596 for sale

URL successfully copied!

Tap to zoom

ID: 9006596

Vintage: 2004

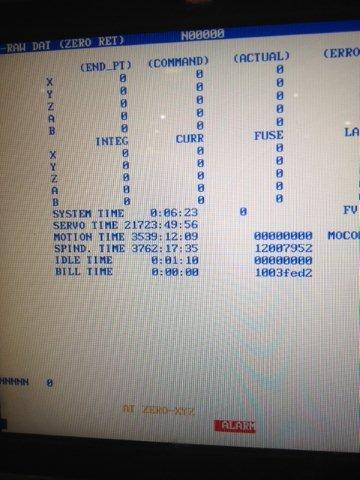

CNC vertical machining center

Travels:

X-axis: 50"

Y-axis: 20"

Z-axis: 25"

Spindle nose to table: min 4", max 29"

Table:

Length: 52"

Width: 18"

T-slot width: 5/8"

T-slod center distance: 3.15"

(5) Standard T-slots

Spindle:

Max rating: 30 HP

Max speed: 10,000 rpm

Taper: CT

Bearing lubrication: air/oil injection

Feed rates:

Rapids on X: 1,000 in/min

Rapids on Y: 1,000 in/min

Rapids on Z: 1,000 in/min

Max cutting: 650 in/min

Axis motors:

Max thrust X: 2,550 lbs

Max thrust Y: 2,550 lbs

Max thrust Z: 4,200 lbs

Capacity: 24

Air required: 4 SCFM, 100 psi

195-260 VAC, 50 A (options may increase requirement)

Equipped with:

High intensity lighting

Hight torque: 10,000 rpm

2-speed gearbox

24 tool side mount

Programmable coolant

Chip auger

Remote jog handle

Macros

Coordinate rotation and scaling

Rigid taping

Coolant tank

High pressure thru spindle coolant

2004 vintage.

HAAS VF-4 is a high-end industrial CNC (Computer Numerical Control) vertical milling machine used for machining parts used in a variety of industries such as aerospace, automotive, medical, military, energy and oil production. HAAS VF 4 is capable of machining parts to highly precise tolerances and features several advanced features designed to increase the efficiency of the production process. VF-4 features a rigid steel frame and is powered by a 30 hp vector drive motor and a 4 axis CNC control system. It has a solid cast base with a Belt-Style Auto Tool Changer (ATC) and a 24-position ATC magazine. The maximum spindle speed is 8,100 RPM. The spindle is supported by a large diameter trunnion table that gives up to 8 inches of Y-axis travel. The maximum work piece envelope on VF 4 is 20" X 16" X 20" and the table size is a generous 49.5" x 18" that can handle as much as 800 pounds of material. The machine is also equipped with an OML rotary encoder that is designed to reduce setup times and simplify operation. Other features of HAAS VF-4 that increase accuracy and speed include a programmable coolant nozzle, a high-pressure coolant system that is filament cooled, and an air blast for improved chip handling. The machine also features an optional 5th axis halve headstock which supports 3-dimensional part work. HAAS VF 4 is designed to provide a high degree of safety as a removable keypad indicator warns operators when the control is in an unsafe mode. The machine also features a built-in lubrication system that provides automatic lubrication to the spindle and bearings extending its life and improving performance. VF-4 is capable of high speed top-end performance and can be used to produce highly precision parts with tight tolerances. VF 4 is backed by one of the best warranties in the industry and extended service plans are available for additional coverage. The machine is also well covered by highly trained service technicians and provides excellent customer support.

There are no reviews yet