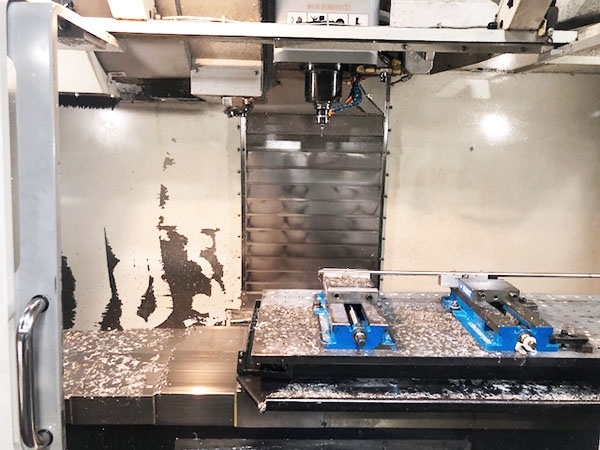

Used HAAS VF-4 #9215493 for sale

URL successfully copied!

Tap to zoom

ID: 9215493

Vintage: 2006

Vertical machining center

X - Axis travel: 50"

Y - Axis travel: 20"

Z - Axis travel: 25"

Table size-l: 54"

Table size-w: 18"

Spindle taper (cat/bt): CAT 40

Tool changer type: 24+1

Spindle speed: 8,100 RPM

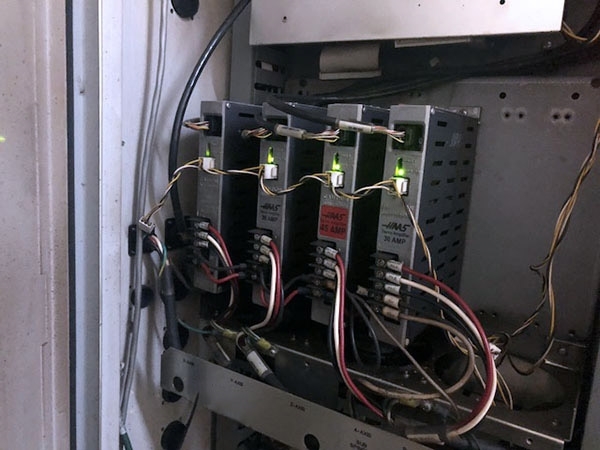

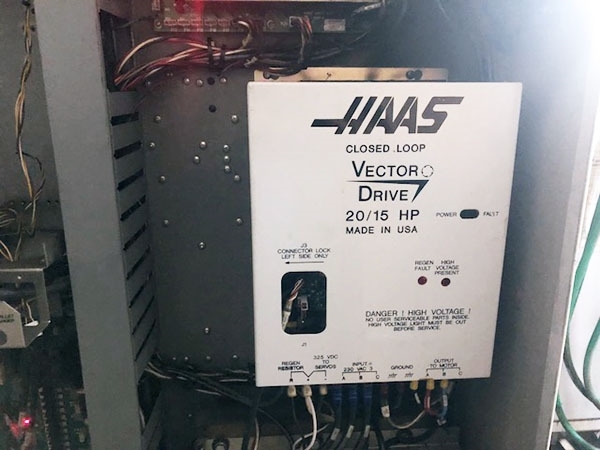

Spindle motor: 20 HP

Equipped:

Chip conveyor

NC swivel head with HSK50

48 Tool position upgrade (47 pockets)

Coolant equipment KF 150/KFA 500

208VAC-480VAC transformer

Glass sales in all axes

Fixture flush 1 zone

Flow control switch (for fixture washing)

Automatic central lubrication

Preparation for mist collector and mist collector

Technology for turning from bar 65mm diameter

Lathe spindle (65mm diameter 4500RPM)

NC turning unit with hydraulic clamp vice HZS110-z

Hydraulic unit for vice with clamping tools

Machine table with 2 mounting surfaces

RENISHAW probe package (omp 40-2LS)

Chiron laser control 40

Torit mist control system

1000 PSI high pressure pump - knoll

Thru the tool coolant

2006 vintage.

HAAS VF-4 is a top-of-the-line CNC machining center designed to provide maximum power and capability for the toughest machining jobs. This high-performance machine provides four paths of travel (X, Y, Z, and W) in a large machining envelope. It also offers an expansive work envelope of 40" x 20" x 25" (1016 x 508 x 635 mm). HAAS VF 4 has a powerful 33.5 hp (25 kW) vector drive spindle, which can produce speeds up to 10,500 rpm and a maximum spindle torque of 143 ft.-lbs. (195 Nm). The automatic tool changer is a 20-station and offers a tool capacity of up to 60 lb. (27 kg). It also has a dual position turret which reduces non-cut time for improved productivity. The design of VF-4 includes a rigid frame construction, an innovative dual-balance separation of drive/torque generators, and vibration damping design. The combination of these features, plus the use of precision class linear guide ways, provides exceptional vibration damping and stiffness and ensures superior accuracy and surface finish. The T-slot table design provides flexible, robust mounting options for jigs and fixtures. The ability to load multiple fixtures onto a single table can significantly reduce set-up and production times. The direct-coupled harmonic gearbox spindle design and 1-degree high-resolution indexing allows for quick, accurate indexing of both standard and ATC tools. Designed for maximum versatility, VF 4 machine can be programmed for one-off parts production or small and medium batch production runs. HAAS VF-4 is powered by the latest version of HAAS fully customisable, menu-driven control with a 10.4-inch full-color LCD display. This CNC control provides exceptional accuracy and repeatability, while also offering comprehensive G-code and conversational programming functions for improved productivity. This machine is equipped with highly intuitive graphical operation screens, which help simplify programming operations. Overall, HAAS VF 4 is a highly capable machine that is designed to handle all kinds of machining jobs. With its expansive work envelope, high-torque spindle, robust frame construction, and intuitive control, this machine can deliver superior performance and accuracy for any machining application.

There are no reviews yet