Used HAAS VF-5D/40 #9204439 for sale

URL successfully copied!

Tap to zoom

ID: 9204439

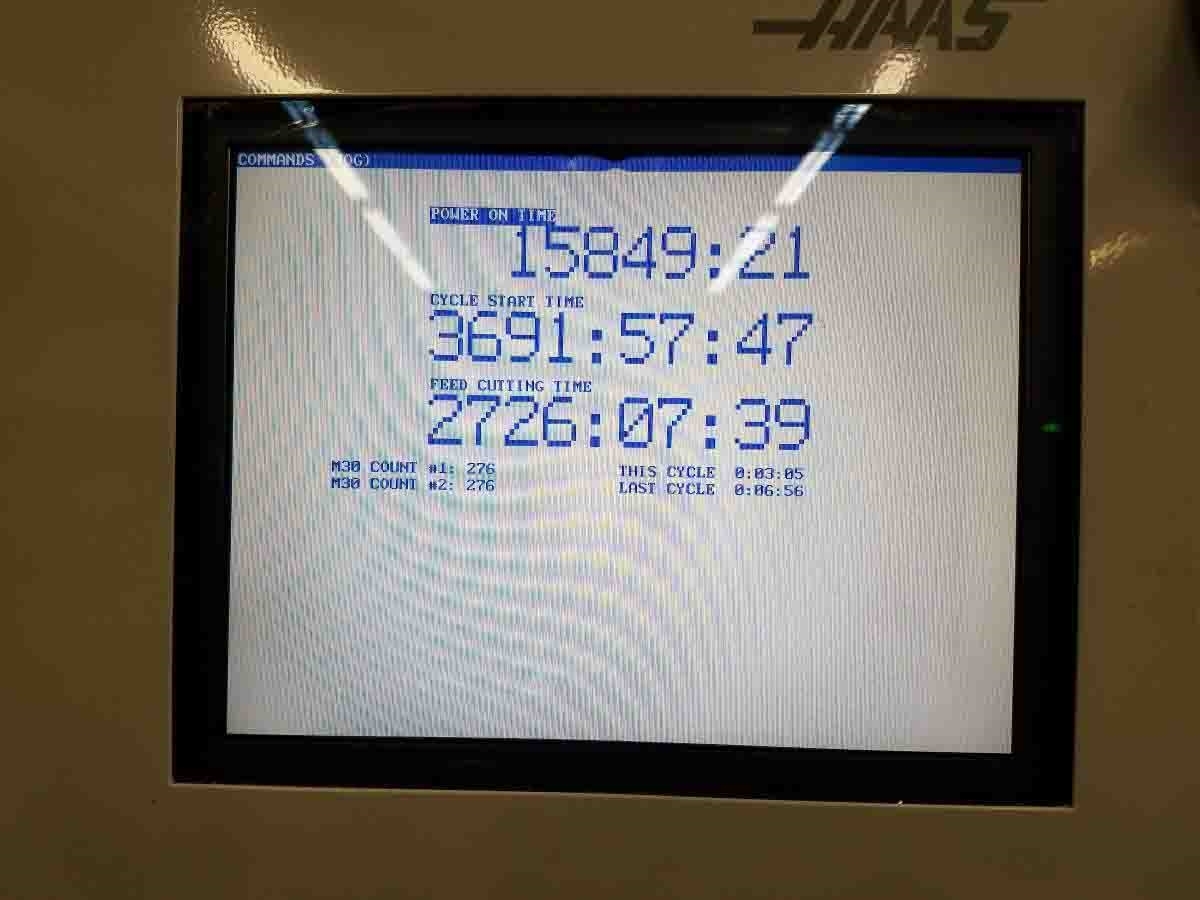

Vintage: 2003

CNC Vertical machining center

4th axis & clean

Travel:

X Axis (Inches): 50"

Y Axis (Inches): 26"

Z Axis (Inches): 25"

Rapid traverse rates: 710 IPM

Spindle taper: CAT 40

Spindle motor: 20 HP vector drive

Spindle speed: 15,000 RPM

Spindle nose to table top: 7"-32"

Table size: 51" x 23"

Table load capacity: 4,000 lbs

2003 vintage.

HAAS VF-5D/40 is a high-performance vertical machining center designed for demanding industrial requirements. It has a high-speed spindle and advanced motion control that provide superior machining capabilities for a wide range of hard materials. The large working envelope and T-slotted table make it suitable for five-axis machining applications, as well as typical three-axis operations. The VF-5D/40 has an X, Y, and Z axis travel of 50" x 20" x 25" with an impressive 5-axis travel of 16". It features a 40-taper spindle that can reach a top speed of 15,000 RPM and is powered by a 30+hp vector drive. The spindle is cooled with an internally integrated oil-air mist system. A 100-SID (Side Interchangeable Tool) Toolchanger and dual-arm ATC (Automatic Tool Changer) allow for reduced hoist time and virtually uninterrupted production. The standard HAAS control system offers an intuitive user interface with a modern graphical display, as well as full conversational programming capabilities and direct numerical control (DNC) functions. The high-speed servo control features advanced lookahead and acceleration/deceleration control functions to minimize cycle time and provide even, smooth motion. HAAS VF-5D/40 can be equipped with many options, including a 4th and 5th axis rotary table, high-flow coolant systems, dual-cyclone automatic chip augers, embedded vision systems, and much more. The large work envelope, high-speed spindle, and advanced motion control make the VF-5D/40 an excellent choice for multi-axis machining applications. It is ideal for high-speed, high-precision machining of a wide range of materials, including hard metals and plastics. The built-in flexibility of the machine ensures optimal performance for a broad range of industrial requirements.

There are no reviews yet