Used HAAS VF-6/50 #9242653 for sale

URL successfully copied!

Tap to zoom

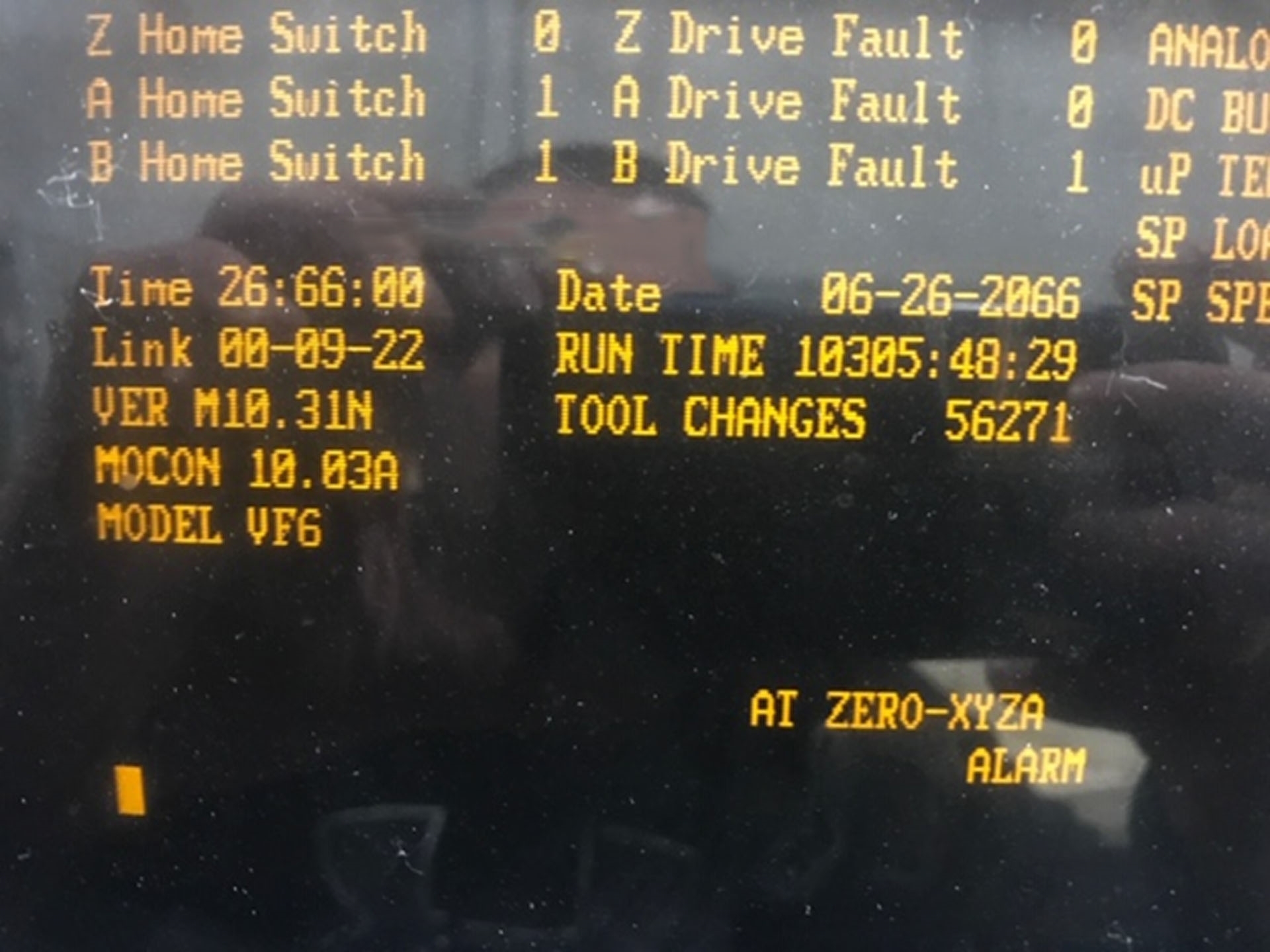

ID: 9242653

Vintage: 2000

Vertical machining center

Travels:

X-Axis: 64"

Y-Axis: 32"

Z-Axis: 30"

Equipped with:

30HP High torque spindle motor

4th Axis, 12”

Remote jog handle

Rigid tapping

Programmable coolant

Telescopic way covers

Chip auger

Floppy drive

Flood coolant system

Rapid traverse rates: 600" / min

Cutting feed rates: 500" / min

Spindle nose to table (min-max): 5"–35"

Table:

Length: 64"

Width: 28"

Number of std T-slots: 5

T-Slot width: 5/8"

Spindle:

Taper size: CAT 50

Speed range: 0–10,000 RPM Geared head

Spindle power: 30 HP Vector dual drive

Max torque: 90ft-lb @ 2000RPM

Automatic tool changer:

Capacity: 30+1

Max tool diameter: 6"

Max tool length: 16"

Tool changing time: 4.2 seconds

Air required: 100 psi, 4 scfm

Power: 220 V / 66 FLA / 3 Phase

2000 vintage.

HAAS VF-6/50 is a machine tool used for high speed trimming and precision machining. It has a large work table with a 50-inch by 26-inch footprint and can travel up to 50 inches along the X-axis and 26 inches on the Y-axis. HAAS VF-6 / 50 is equipped with a Fanuc 31i-B5 CNC control, allowing for precision digital machining operations. The spindle on VF-6/50 is powered by a 30-horsepower AC digital drive motor and operates at speeds up to 8000 rpm. This spindle is equipped with a standard CAT-40 taper tool holder. VF-6 / 50 can be programmed with various cutting tools, such as milling, drilling, tapping, contouring and reaming. The machine also has a robust steel construction with heavy-duty castings to ensure accuracy and durability. It comes with a single-piece steel base and column construction with a Meehanite cast iron main body to ensure rigidity. The seven-layer labyrinth gearbox is designed for maximum rigidity and vibration dampening. For high-speed milling applications, HAAS VF-6/50 has a24-position tool changer with a fast tool-to-tool selection time of 1.8 seconds. The machine can also take full advantage of its 15HP high-speed vector AC drive attachments with up to100 ft/min rapids and fast 10,000 block look ahead. The machine utilizes a 40-stations Automatic Tool Length Measurement System (ATLM) to monitor tool length in real time and reduce setup times. The ATLM system also ensures that tools are set precisely and that tool breakage is decreased. In terms of safety, HAAS VF-6 / 50 is equipped with an integral automatic door guard to ensure operator safety and reduce setup time for operators. It also has a chip guard to shield against flying chips and particles. VF-6/50 is a high-performance precision machining tool with a robust steel construction and many safety features. It is designed to reduce setup time and provide high-speed milling operations. This machine can be used for a wide variety of precision manufacturing operations, including milling, drilling, tapping, contouring and reaming. If you are looking for a versatile and reliable machine for precision parts production, VF-6 / 50 is an excellent choice.

There are no reviews yet