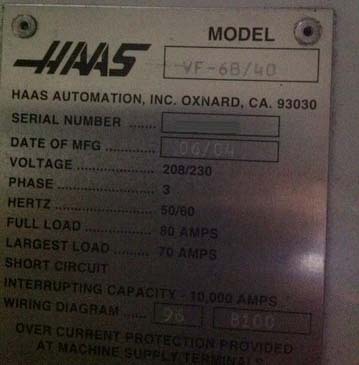

Used HAAS VF-6 #9006601 for sale

URL successfully copied!

Tap to zoom

ID: 9006601

Vintage: 2004

CNC vertical machining center

Travels:

X-axis: 64"

Y-axis: 32"

Z-axis: 30"

Spindle nose to table: min 4", max 34"

Table:

Length: 64"

Width: 28"

T-slot width: 5/8"

T-slod center distance: 4.92"

(5) Standard T-slots

Max weight on table: 4,000 lbs

Spindle:

Max rating: 30 HP

Max speed: 10,000 rpm

Taper: CT

Bearing lubrication: air/oil injection

Cooling liquid

Type: SMTC

Capacity: 24+1

Max tool diameter (adjacent empty): 6"

Max tool diameter (full): 3"

Max tool length (from gauge line): 16"

Max tool weight: 12 lbs

Tool-to-tool (avg): 2.8 sec

Chip-to-chip (avg): 3.6 sec

General:

Air required: 4 SCFM, 100 psi

Coolant capacity: 95 gal

Equipped with:

High intensity lighting

Hight torque: 10,000 rpm

2-speed gearbox

24 tool side mount

Programmable coolant

Chip auger

Remote jog handle

Macros

Coordinate rotation and scaling

Rigid taping

Coolant tank

High pressure thru spindle coolant

Power 195-260 VAC, 100 A / 354-488 VAC, 50 A

2004 vintage.

HAAS VF-6 vertical machining center is a heavy-duty production-based machine used for machining large or complex parts. It is designed for high speed machining, allowing you to produce exceptional surface finishes without sacrificing part quality or accuracy. VF-6 features a robust and rigid design with an 84" x 32" x 30" travels in the X-, Y-, and Z-axis respectively and can handle payloads up to 11,182 lb. Its massive work envelope is great for machining large, complex components. HAAS VF-6 features a semi-enclosed design for a much quieter working environment. It has an array of advanced features designed to increase accuracy, output, and flexibility of the machine. VF-6 features a 15,000 RPM spindle that can be upgraded up to 20,000 RPM if needed for higher speed machining applications. It also has a 30 HP Vector Dual-Drive Spindle Motor that enables faster feedrates and more torque. Furthermore, HAAS VF-6 also boasts an automatic pallet changer with a quick-change tool changer that enables faster cycle times and reduced setup time. VF-6 has the ability to take on a variety of different machining processes such as drilling, tapping, contouring, and slotting, amongst other operations. It is outfitted with a 1,000-block look-ahead, CNC control that facilitates easier programming and smooth, fast machining. Additionally, the efficient chip management system helps keep the workspace and components free of debris for improved machining accuracy and quicker cycle times. For more precise results, HAAS VF-6 is outfitted with a precision ground ballscrew in all three axes. The backlash compensation and encoder feedback ensure excellent accuracy with all standard and repeatable features throughout production. Furthermore, it features a high-speed centrifugal cooling system to keep critical components and parts cool during long machining cycles. Overall, VF-6 is a reliable machine built to produce consistent and quality results. Its heavy-duty design provides great rigidity and long-lasting durability, making it a great choice for a variety of machining applications. Additionally, its advanced features give it the flexibility to handle the most demanding machining jobs with relative ease.

There are no reviews yet