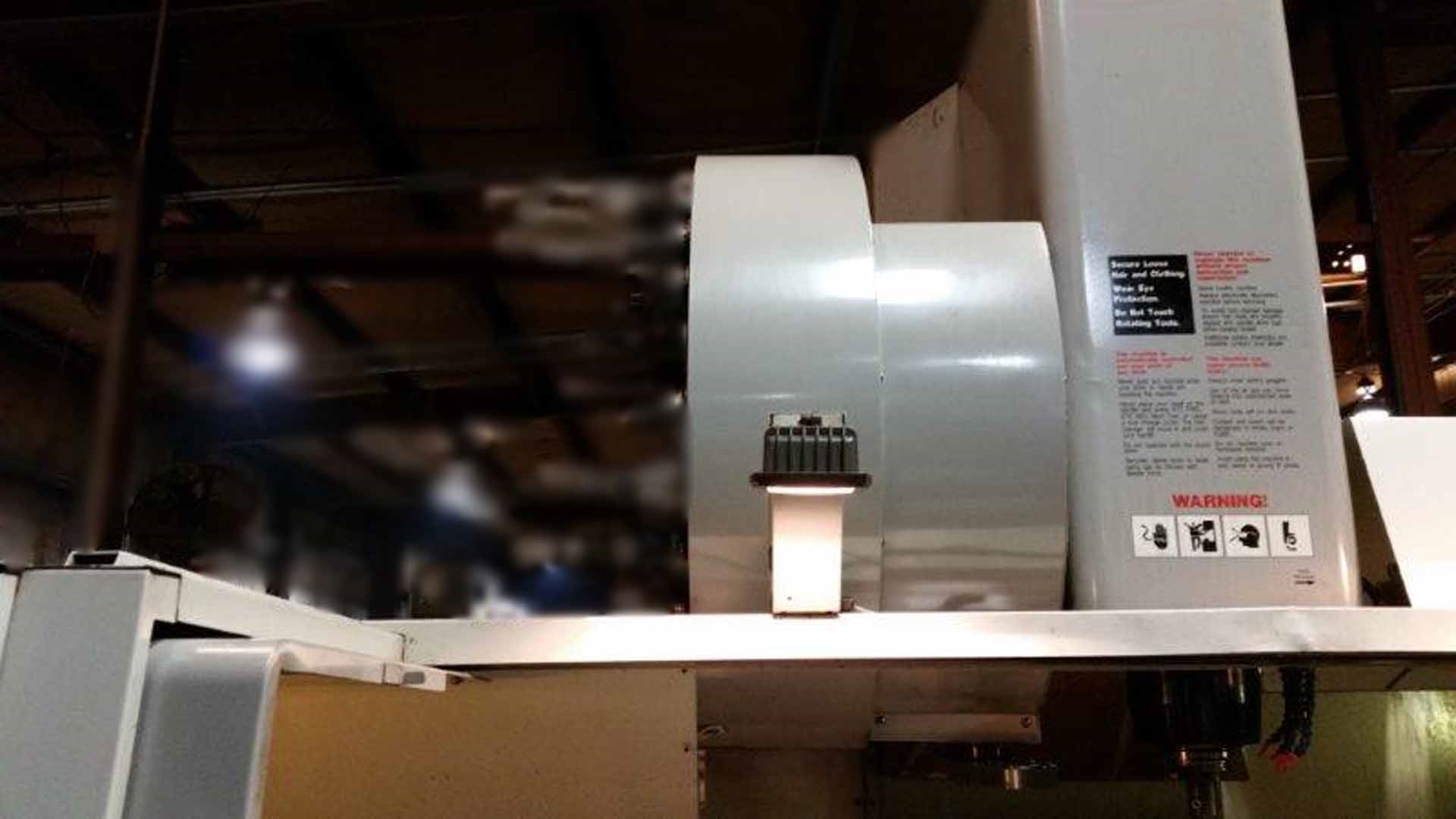

Used HAAS VF-9/50 #9205635 for sale

URL successfully copied!

Tap to zoom

ID: 9205635

Vintage: 2008

CNC Vertical machining center

Table size: 36" X 84"

Travels:

X-Axis: 84"

Y-Axis: 40"

Z-Axis: 30"

Spindle nose to table minimum / Maximum: 5/35"

Rapid traverse X / Y / Z: 600 IPM

Maximum cutting: 500 IPM

Maximum torque: 340 Ft-Lb at 700 RPM

Main motor: 30 HP

Spindle taper: CAT 50

Tool changer side mount: 30 ATC

Spindle speed: 7500 RPM

Equipped with:

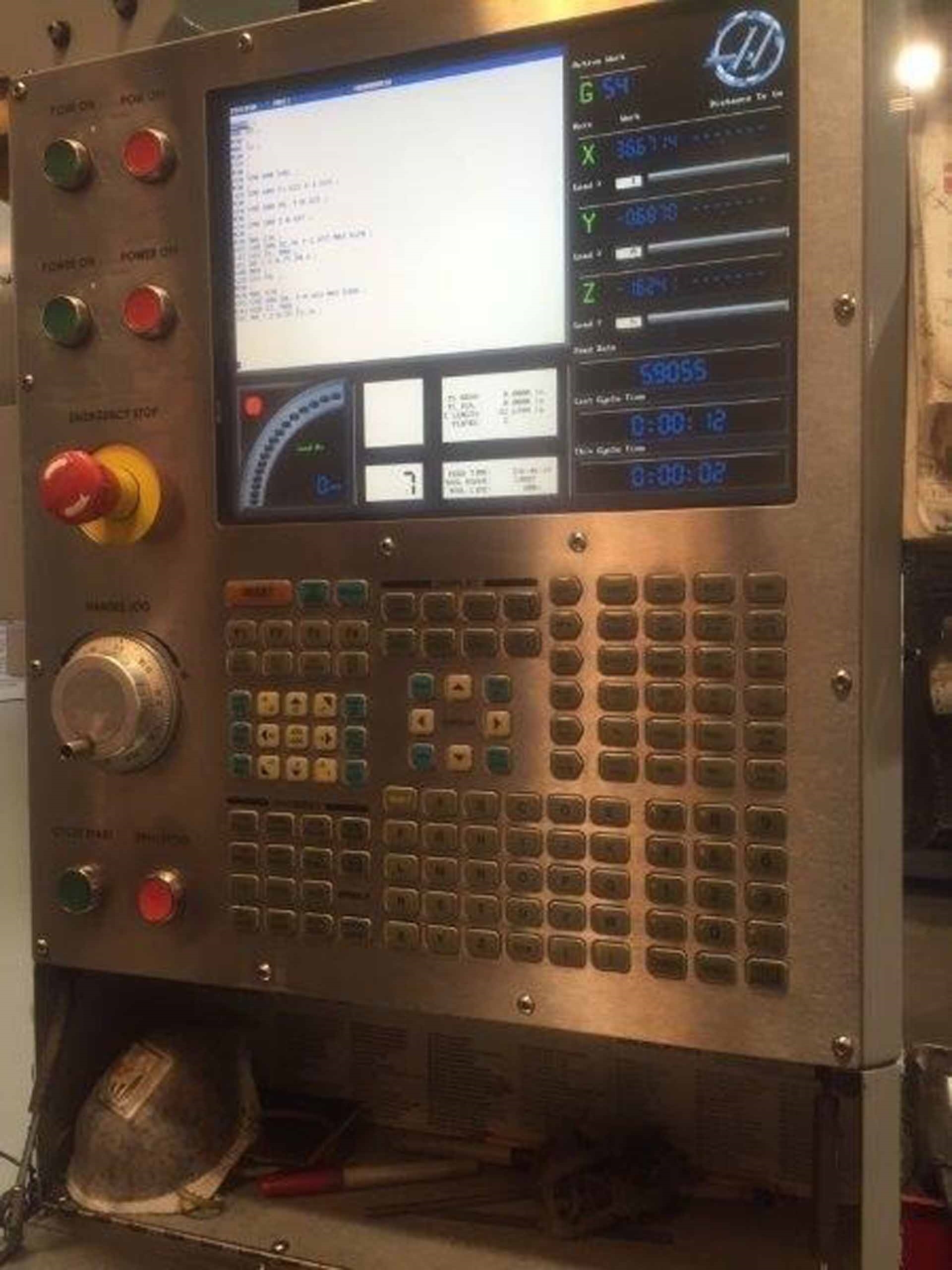

HAAS CNC Control

Key switch memory lock for front pendant

2-Speed geared

High intensity lighting

Rigid tapping

Coolant through spindle

Flood coolant system

Programmable coolant

TSCHP55 gallon CLNT Auxiliary filter

HIP Auger

Chip auger

Manuals included

2008 vintage.

HAAS VF-9/50 is a professional-grade vertical machining center (VMC) that provides producers with superior precision and productivity. This machine tool is a reliable workhorse with its 50-taper spindle and robust permanent-magnet spindle motor, making it well suited for handling both high-loads and high-speed applications. The VF-9/50 is a three-axis production machine tool that features a spacious 50" x 20" x 25" work envelope which provides ample space for any part-making need. It is built with an oversized linear guide ways, providing the machine with a maximum X/Y/Z rapid traverse rate of 1,400/1,400/1,000 ipm. It has a maximum cutting feedrate of 690ipm in all three axes as well as the drill capacity to support heavy-duty applications. The trunnion-style rotary table which supports a maximum table load capacity of over 1,200kg and includes a fast axis for efficient indexing abilities. HAAS VF-9/50 also includes numerous features designed to maximize productivity and ensure accurate performance. It has an integrated, high-power 1,400-watt vector spindle drive system that provides air-conditioned precision spindle speed controllability up to 10,000 rpm with ±0.0001" through-spindle repeatability. Additionally, the VF-9/50 includes direct-coupled centrifugal pumps which provide both full-load cooling and improved thermal stability. HAAS VF-9/50 has a built-in, programmable spindle orientation system for greater accuracy and repeatability, as well as a fully-integrated operator control panel with a door swing arm with straight-through part access. For maintenance, a simple two-piece enclosure design provides quick and easy access. The machine also comes standard with safety systems such as an enclosed machine frame, light curtain, and other safety components to protect operators and machining personnel from harm. HAAS VF-9/50 possesses the capability and the tools to meet a wide variety of needs. The key to its versatility lay in the rigid construction and the accuracy achievable on the workpiece. Whether for full production runs or complex ground pieces, the VF-9/50 provides the operator with the perfect milling machine solution.

There are no reviews yet