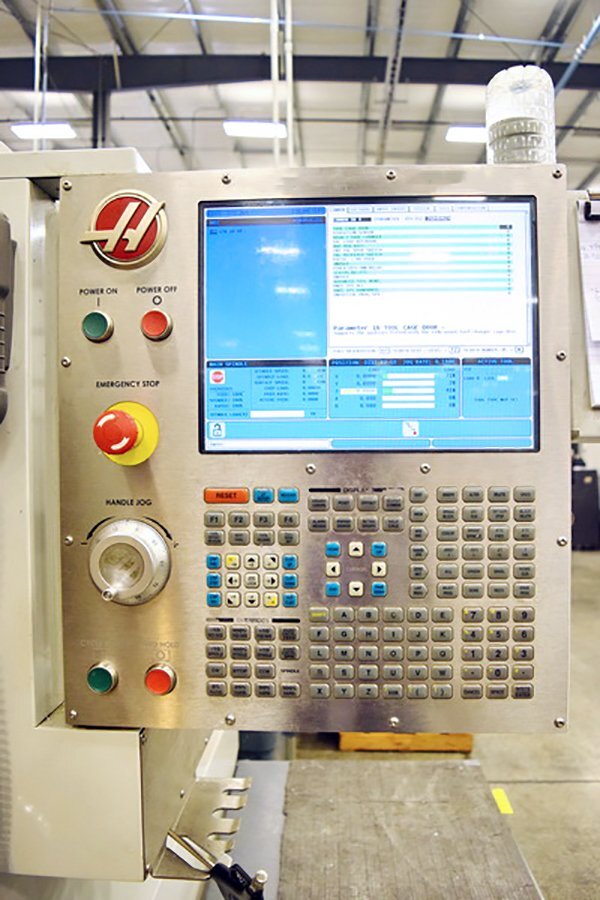

Used HAAS VR-11 #9357792 for sale

URL successfully copied!

Tap to zoom

ID: 9357792

Vintage: 2013

CNC Vertical machine center

5-Axis

Automatic chip auger

Program memory: 750 MB

Rigid tapping

Flood coolant system

Vector drive: 30 HP (22.4 kW)

High intensity lighting

Ethernet interface

32-Station carousel tool changer

Dual halogen lamps door activated

Programmable coolant nozzle: 40 Taper

X-Axis travel: 120"

Y-Axis travel: 40"

Z-Axis travel: 30"

Maximum thrust X/Y/Z: 3400 LB

Maximum rating X: 7.5 HP

Maximum rating Y: 5.0 HP

Maximum rating Z: 5.0 HP

T-Slot width: 5/8 "

A-Axis tilt: ±32°

Maximum cutting A/B: 600° / MIN

Coolant capacity: 95 GAL

Tool to tool (AVG): 11.0 SEC

Bearing lubrication: Air / Oil injection

Repeatability A, B axes: 10 ARC-SEC

T-Slot center distance: 4.92"

Positioning A, B axes: ±45 ARC-SEC

Drive system: Vector drive

Taper: CT40

Table size: 120" x 28"

Tool changer: 32 ATC

Maximum speed: 15,000 RPM

Maximum rating: 30 HP

Maximum cutting: 360"/MIN

Rapids on A / B: 1900°/MIN

Rapids on X: 360"/Min

Rapids on Y, Z: 600"/MIN

Air required: 9 SCFM, 100 PSI

B-Axis rotation: ± 32°

Spindle nose to table: 4"-34"

2013 vintage.

HAAS VR-11 is a high-precision CNC 5-axis vertical machining center. This extremely versatile machine tool offers industry-leading performance for both high-speed and high-precision machining. It is designed by HAAS Automation, the world's largest cnc machine tool manufacturer. VR-11 features a vertical spindle and axis design as well as a rigid structure. This allows it to quickly and accurately produce precision parts at optimal speeds and with minimal chatter. The column and spindle on HAAS VR-11 is designed from one piece of high-grade tool steels that give the machine its inherent rigidity and stiffness. Its bed consists of a pair of T-type slots that run the entire length of the bed. The slots reduce thermal expansion and provide a reliable support system for the cutting tool. This makes it possible to maintain high precision and accuracy during machining operations. VR-11 has a two-speed spindle design that allows for the highest cutting speeds in its price range. This makes it optimal for high-speed production of precision parts. The spindle is capable of up to 12,000 rpm and has a full 5-axis synchronous machining capability. This allows the operator to achieve complex part geometries with less setup time and fewer tools. The machine also features a cast iron base for improved rigidity and stability. The wide work envelope allows for larger parts, and the generous travels and positioning capabilities provide ample tool access. The 24-pocket tool changer makes tool changes quick and efficient, while the 0.001-inch resolution on all axes facilitates high accuracy and repeatability. HAAS VR-11 is equipped with a high-speed logic processor, allowing it to easily handle both 2D and 3D design data. This machine also has advanced contouring capabilities, making it an ideal solution for complex part machining. Finally, the oversized coolant system with high-pressure coolant ensures optimal part cooling and long tool life. In conclusion, VR-11 is an ideal choice for any company looking for high-precision machining of parts with complex geometries. Its two-speed spindle design, cast iron base, and advanced programming capabilities make it a reliable and efficient machine tool.

There are no reviews yet