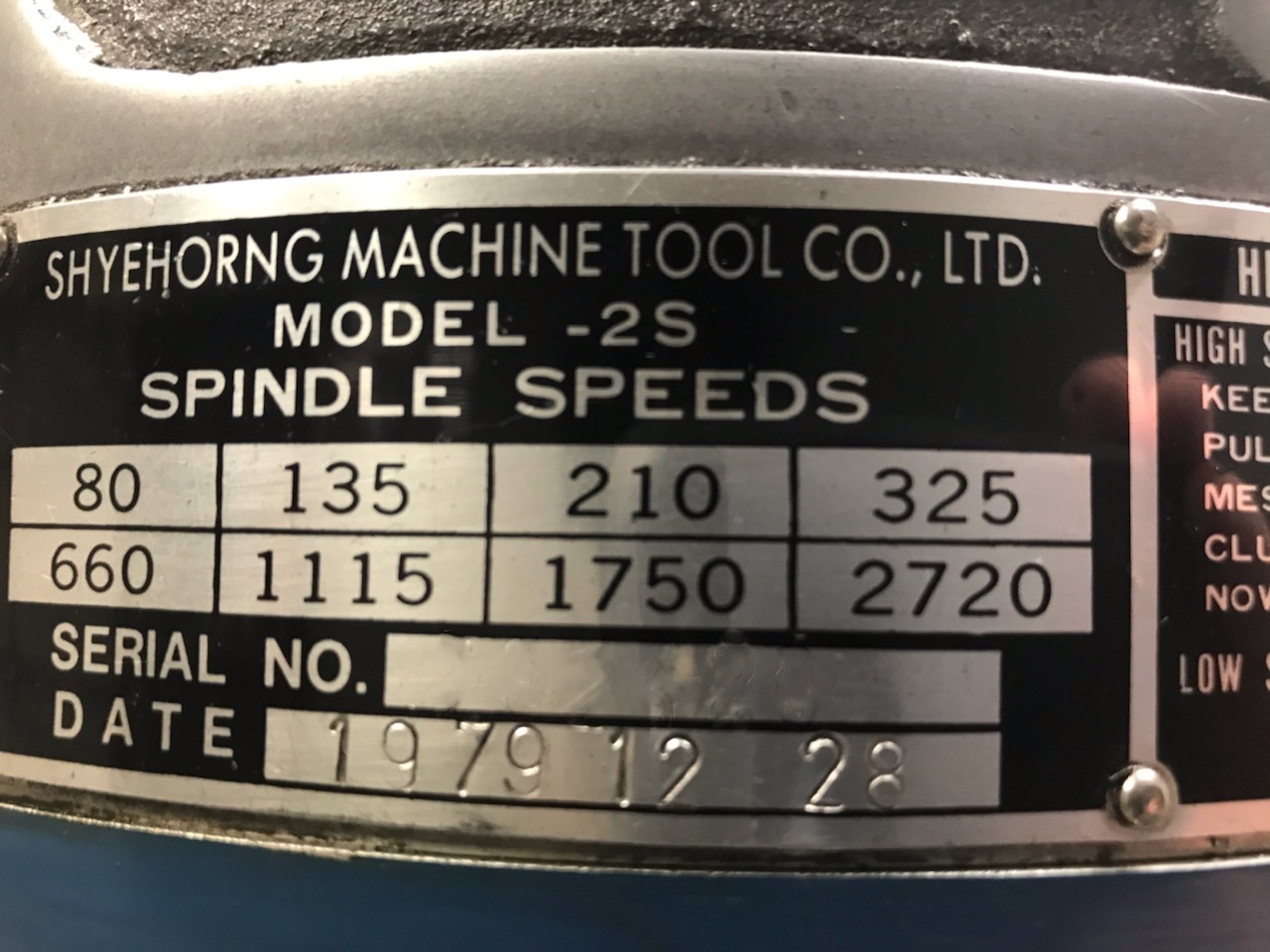

Used HARTFORD 2S #9277914 for sale

URL successfully copied!

Tap to zoom

HARTFORD 2S is a high-precision machine tool designed to deliver precision and accuracy throughout machining operations. It is a multi-functional machine that can be used for turning, tapping, thread milling, and boring operations. The machine is equipped with an array of features and accessories that make it one of the most versatile machines in the industry. The machine consists of a high-precision spindle and headstock, along with an automatic, quick-change tooling equipment. It also features a microscope-style X-Y linear guide rail system, which ensures a precise and controlled machining path for greater accuracy and flexibility. The machine also comes with a slotted tailstock and large working table that is designed to accommodate a variety of workpiece sizes. Additionally, the machine is equipped with a CNC control unit that can be programmed and monitored to achieve complex contouring operations. 2S is designed for high-precision machining and cutting operations, as well as production runs with small and precise features. The robust spindle and operation machine ensure that geometry and tolerance levels are met perfectly. The machine can also be outfitted with various options, such as high-speed tapping attachments, auto feed mechanisms, and multi-axis add-ons, to create a complete machining package. Furthermore, HARTFORD 2S comes with a 100-step programmable cycle counter for faster production rates and handling of multiple cycles with precision accuracy. The handling program also includes an easy-to-understand user interface and a display with programming prompts that make operations easier to understand. 2S offers superior speed, accuracy, and repeatability, as well as savings in edge trims and production costs relative to manual operations. In summary, HARTFORD 2S is a multi-functional machine tool designed for high-precision machining operations. It features an advanced CNC control tool for programming convenience, along with a host of dynamic interchangeable accessories and features to provide superior accuracy and repeatability. Furthermore, the machine's 100-step programmable cycle counter, easy-to-use and comprehensive user interface, and slotted tailstock and working table enable a higher rate of production and quality results.

There are no reviews yet