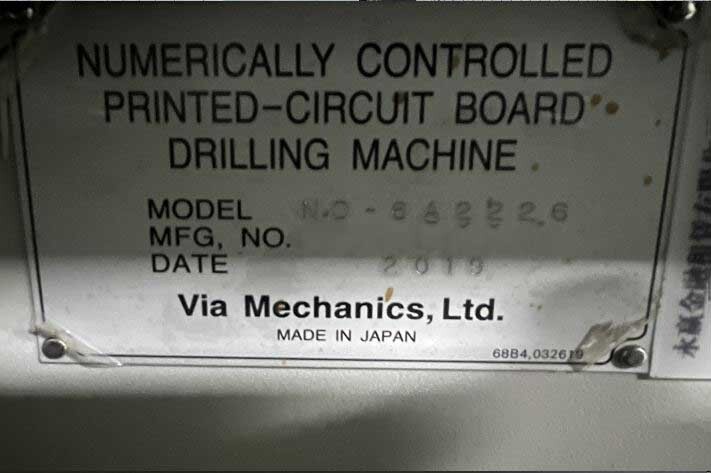

Used HITACHI ND-6A2226 #293639114 for sale

URL successfully copied!

Tap to zoom

ID: 293639114

Vintage: 2019

Drilling machine

6-Axis

Spindle speed: 200,000 RPM

H920E1 Spindle

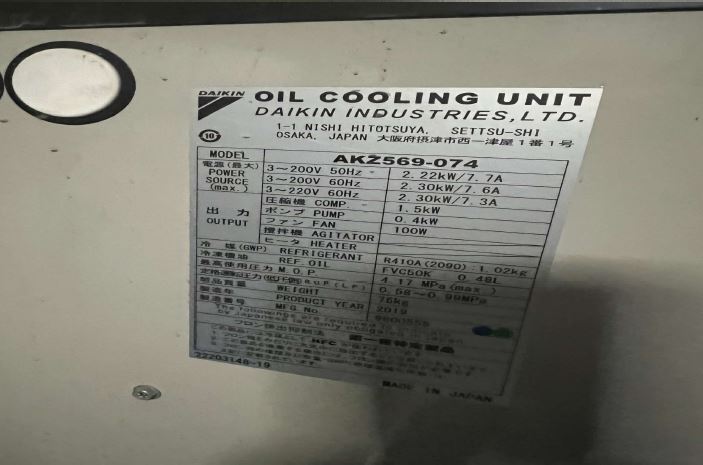

Oil cooler

Dryer

QIC Function

Clip function

Broken needle test

Processing capacity: 0.1-6.35 mm

2019 vintage.

HITACHI ND-6A2226 is a next-generation multi-axis machining center suitable for many different machining operations. The machine is engineered with a sturdy and durable base frame, which helps to reduce vibrations, resulting in quieter and smoother operations. The machine is made up of a column that is slidably attached to the base and a traveling table that is mounted on the base and can be moved in two directions, with two stepper motors providing the power. It is constructed with a wide range of features, including a high-speed spindle, dual and simultaneous 3-axis machining, advanced programing capabilities, and high torque output of up to 2.6 Nm. The machine also provides flexibility and excellent thermostatic stability, and many different cutting tools can be used for different applications. The spindle motor of this advanced machine is driven by a ballscrew with a maximum speed of 11000 rpm. The spindle is wired with high-frequency capacitors and a fan-cooled direct-drive motor with a high thermal overload capacity. This feature helps to reduce the heat produced during machining, thus preserving the integrity of the materials being machined and offering higher precision and quality of the finished product. The machine also features advanced program features to help speed up machining operations. The table of ND-6A2226 has a T-slot to ensure easy tool mounting and easy access to the tool when changing operations. It also features an automatic tool changer that can accommodate up to 20 tools and has a cutting capacity of up to 2.6 Nm. The table is motorized and provides a stable platform for machining operations. The machine also has a high-speed cutting head for fast, accurate and efficient machining operations. HITACHI ND-6A2226 is a versatile, high-performance multi-axis machining center suitable for a wide range of applications. Its high speed spindle motor, 3-axis machining, advanced programing features and high torque output maximizes the precision and quality of the finished product. Its T-slot table and automatic tool changer make it suitable for the rapid production of parts. Its durability, flexibility and thermostatic stability make it ideal for any machining environment.

There are no reviews yet