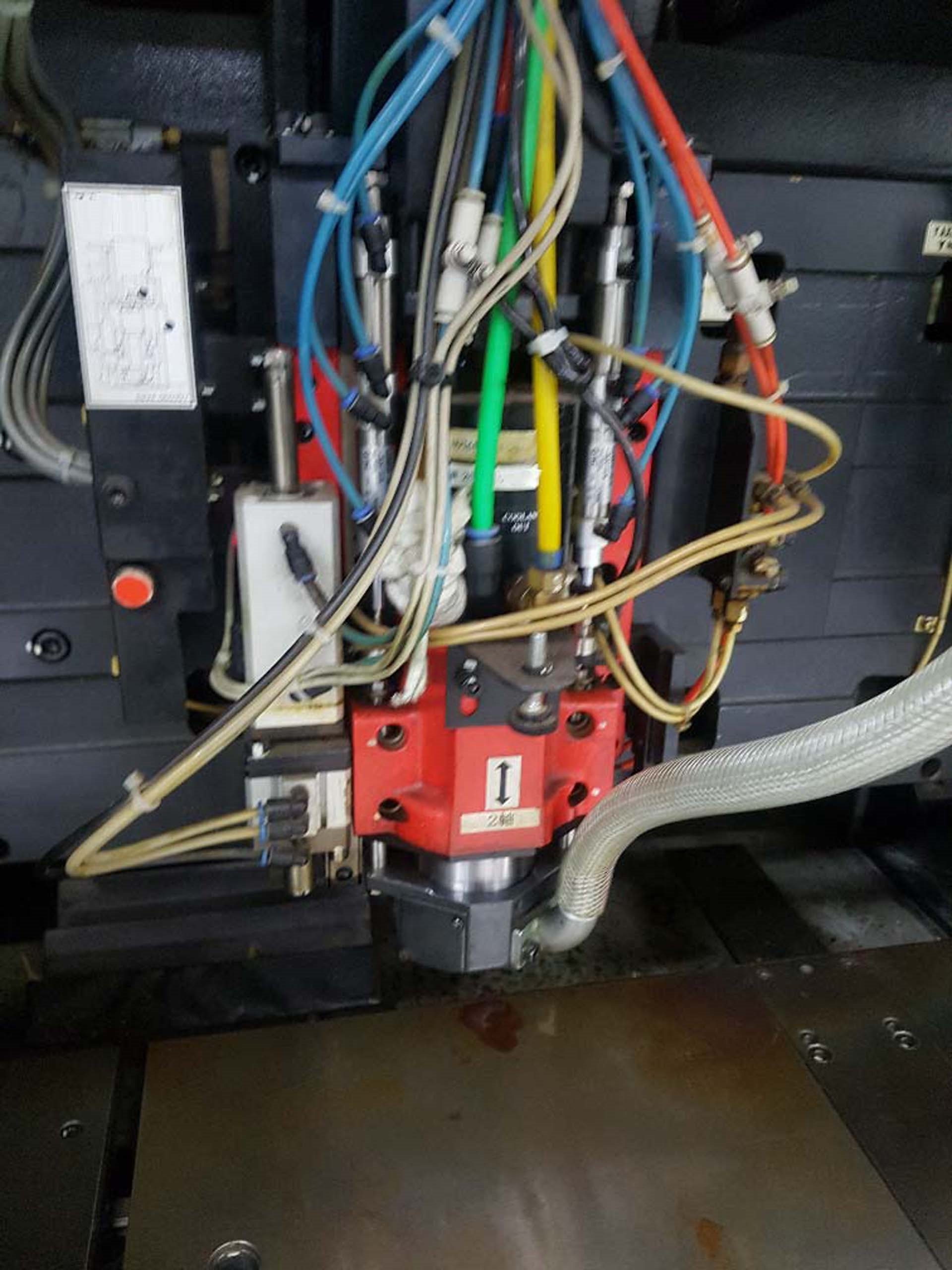

Used HITACHI ND-6L180E #9262738 for sale

URL successfully copied!

Tap to zoom

ID: 9262738

Vintage: 2000

Drilling machines

(6) Heads

Options: 160K, M20D, CCD, BDD, QIC

2000 vintage.

HITACHI ND-6L180E is a cutting edge machine tool designed for precision production. This superior product is the successor of the company's popular ND-5L180E milling machine. ND-6L180E features an increase in cutting performance, rigidity, and reliability over its predecessor. This CNC machine has a wide range of features such as 3-axis CNC with a spindle speed up to 7,500 RPM, a compact design, and superior machine rigidity. Starting with the machine's X, Y, and Z axes, the spindle speed is accurate within the range of 0 to 7,500 rpm, making it perfect for a faster cutting process. The X, Y, and Z axes are equipped with servo motors and linear scales for increased accuracy over its predecessor. The linear scales are encased in dustproof housings that make them reliable and resilient. The linear scales, coupled with the servo motors, make the movements of the axes smooth and precise. The machine has a compact structure that provides rigidity and stability. This allows for highly precise machining parameters. The overall size of the machine is 790x820x1,400mm, which makes it suitable for use in most production spaces. The three axes are supported by two robust guide rails and two roller bearings. Both guide rails and roller bearings are designed for improved rigidity of the machine during machining. The machine uses HITACHI RS-6b CNC controller. This CNC controller provides easy setup, diagnostics, and machining features. It also includes an auto-tuning feature which adjusts to optimum feed speed for maximum surface quality. The RS-6b CNC controller is user-friendly and contains many features such as tool management, program library, macro functions, editing windows, digital input/output controls, error recovery, data storage, and a 3-D graphical display. HITACHI ND-6L180E is loaded with safety features that allow for operator protection when working with the machine. There are two mechanical interlocks that stop the machine when the control box is open; all moving parts stop during this time. There is also a warning system coupled with the control panel that shows any issues with the machine. This prevents any malfunctions and allows for smooth operation of the machine tool. Overall, ND-6L180E is a top-of-the-line machine tool designed for maximum accuracy, rigidity, and reliability. It features a spindle speed up to 7,500 RPM and is equipped with a CNC controller that includes a range of programmable functions. The machine also offers an enhanced level of operator safety and protection.

There are no reviews yet