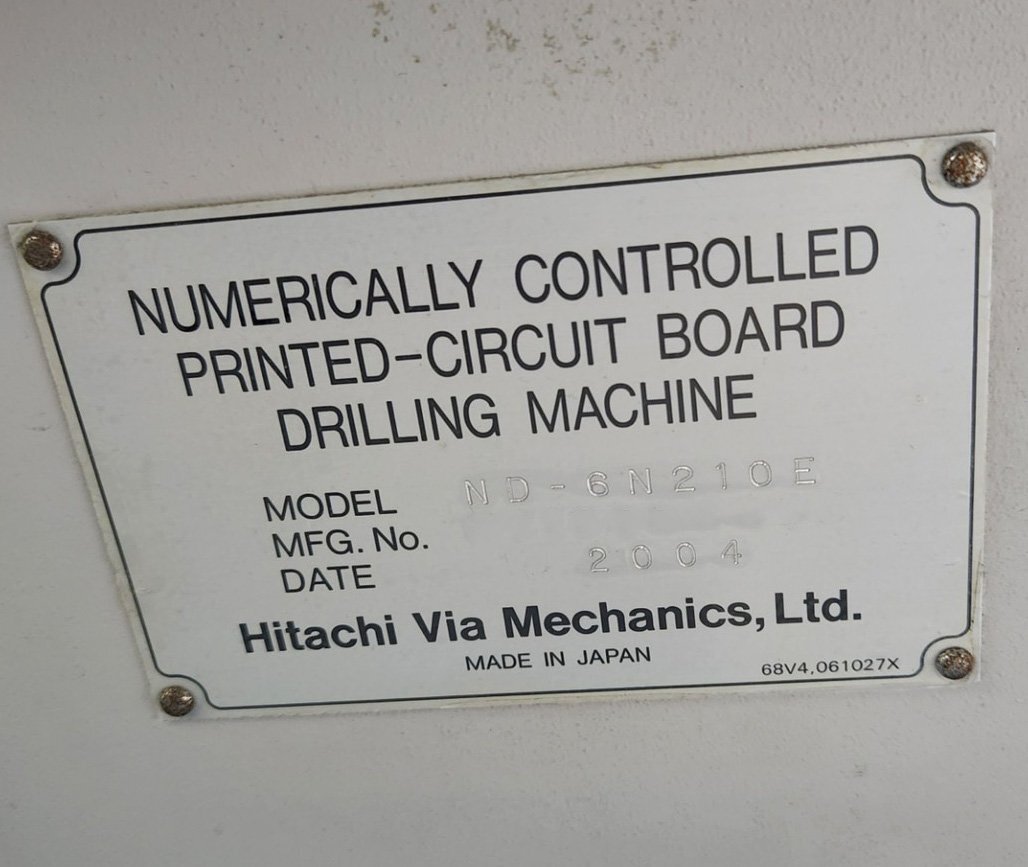

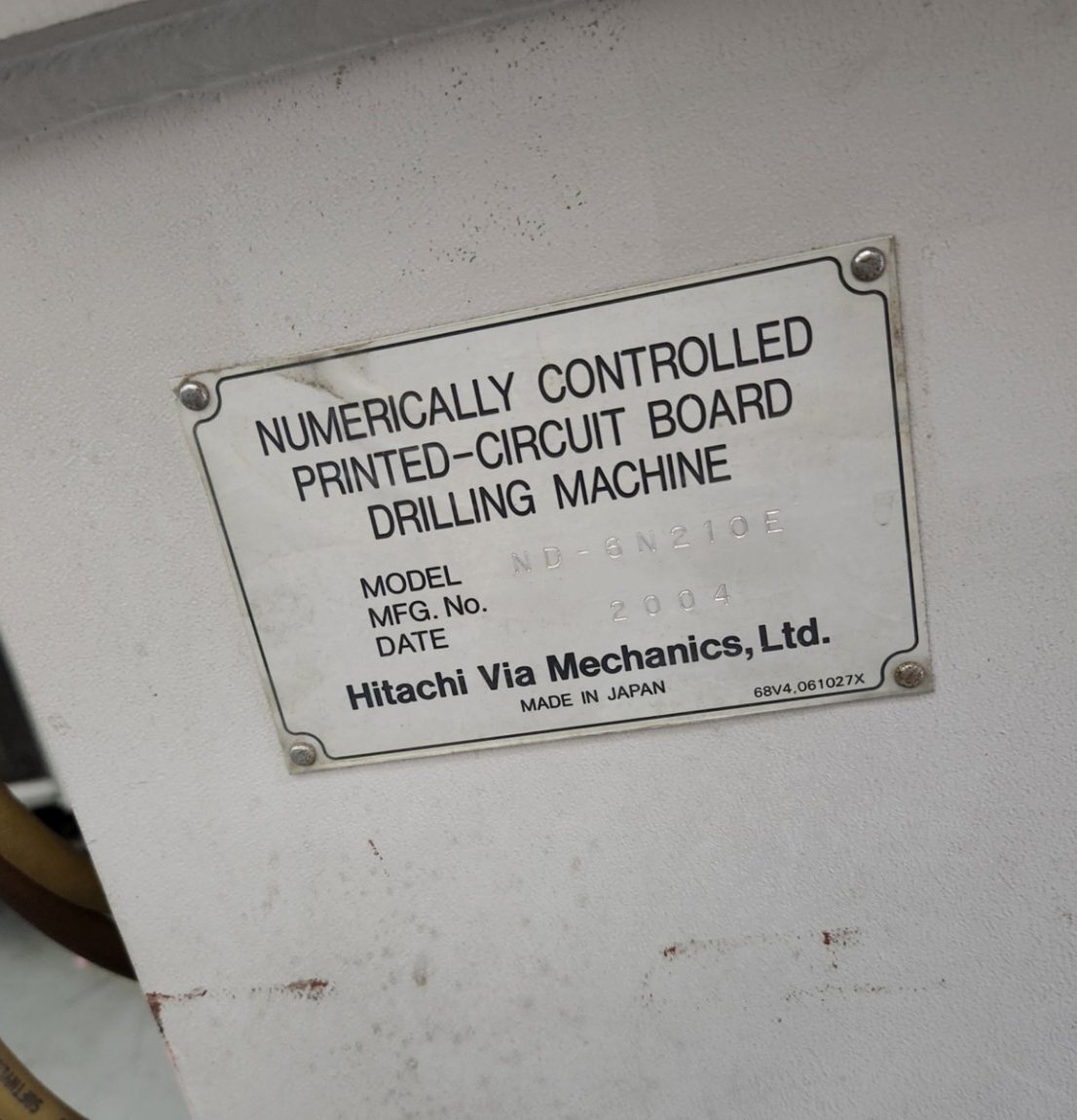

Used HITACHI ND-6N210E #293638992 for sale

URL successfully copied!

Tap to zoom

ID: 293638992

Vintage: 2004

Drilling machines

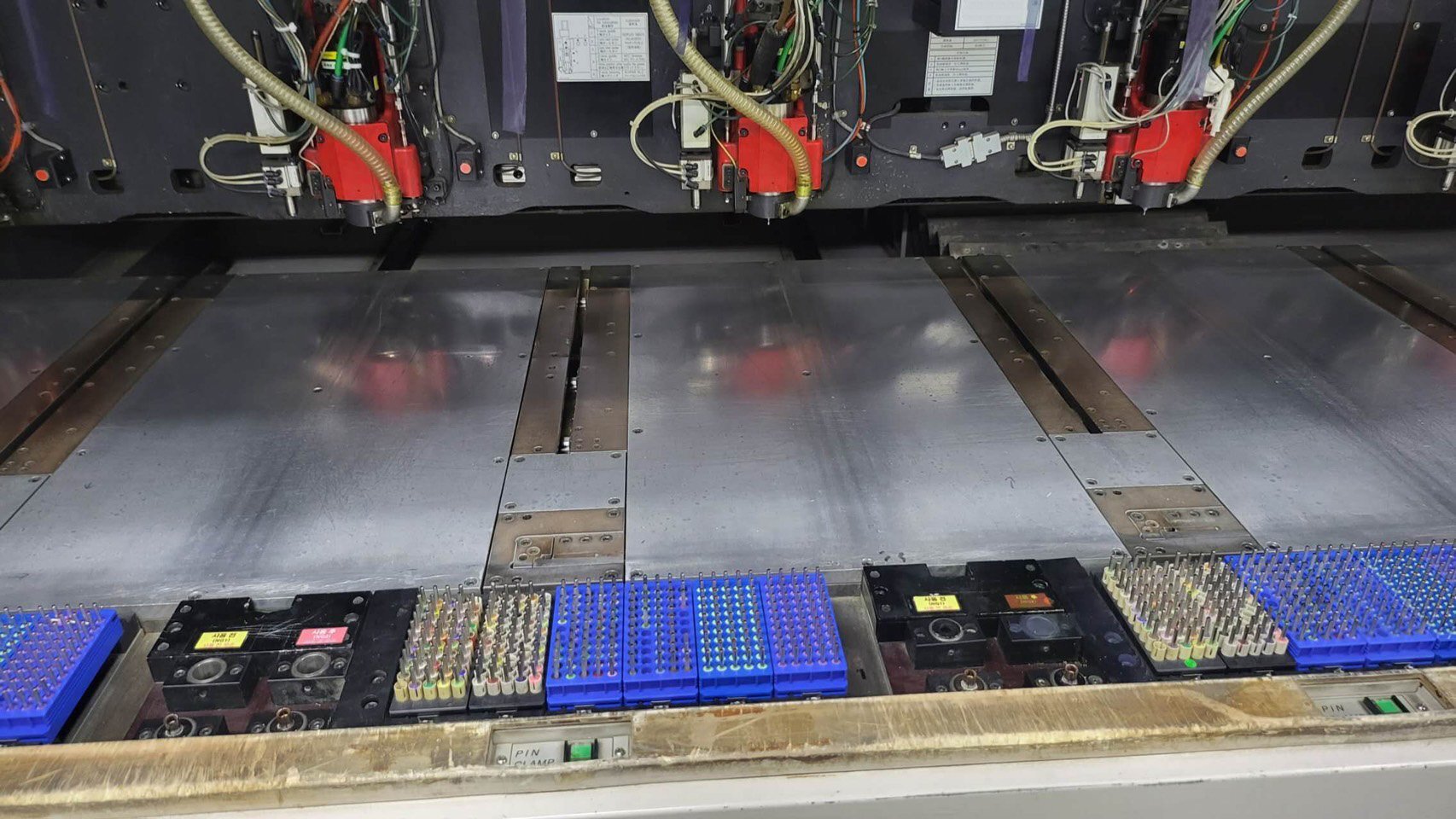

Table: Clamp type

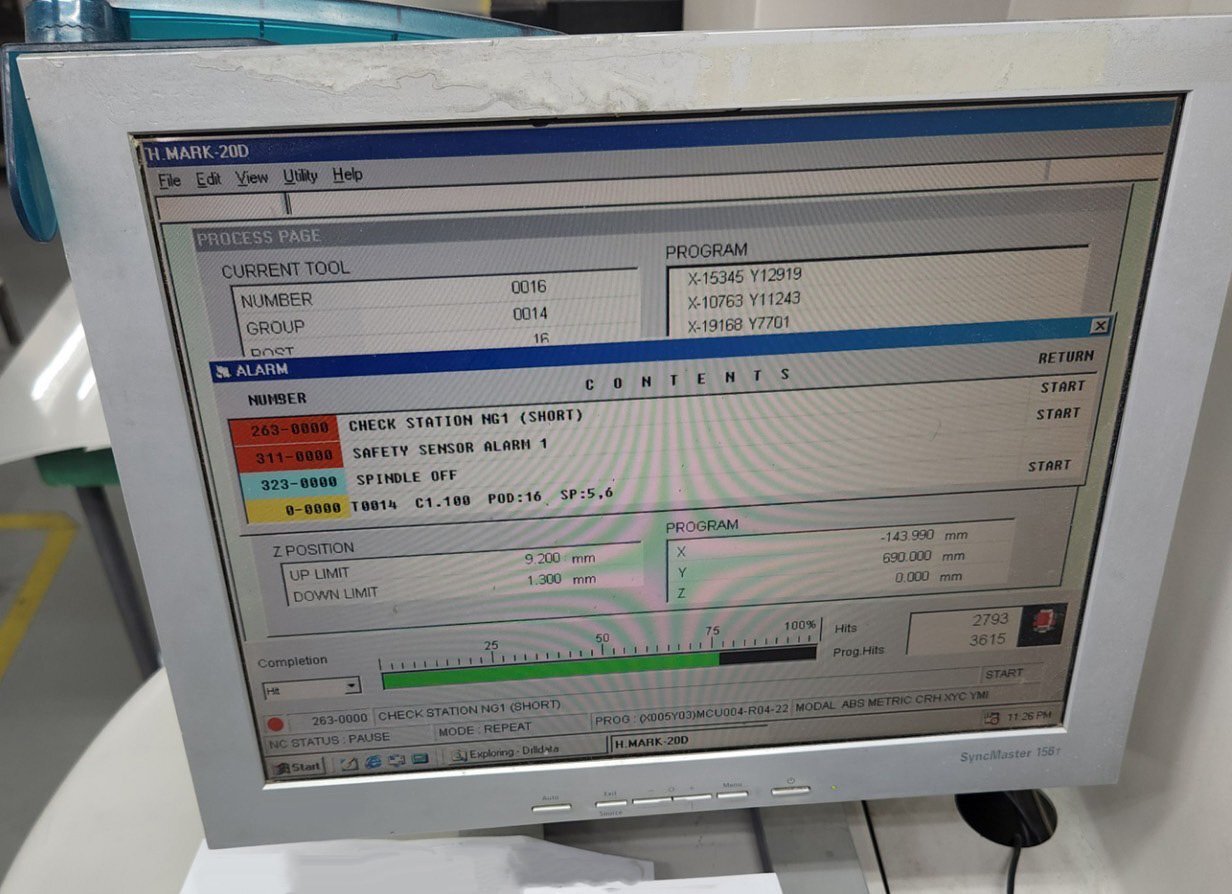

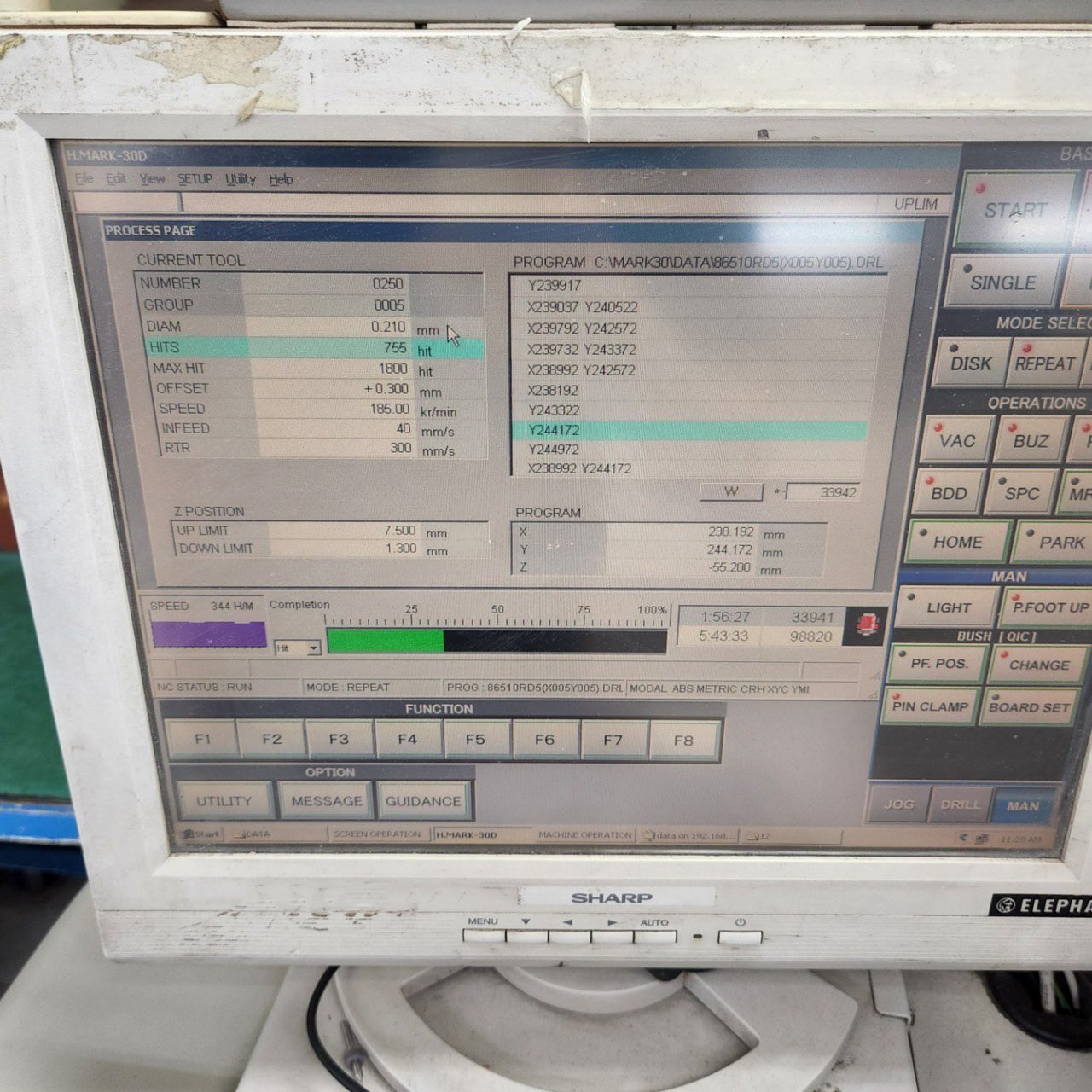

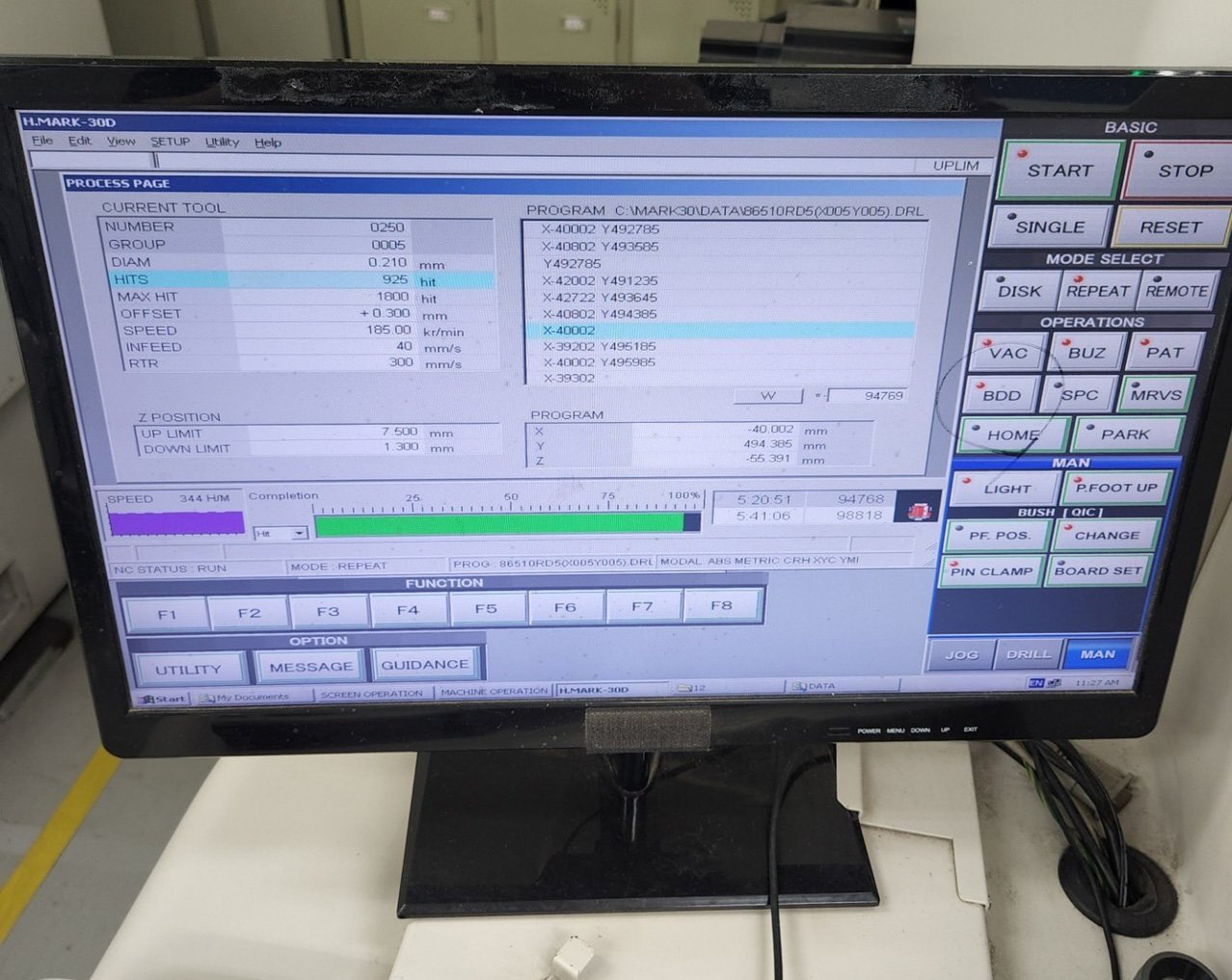

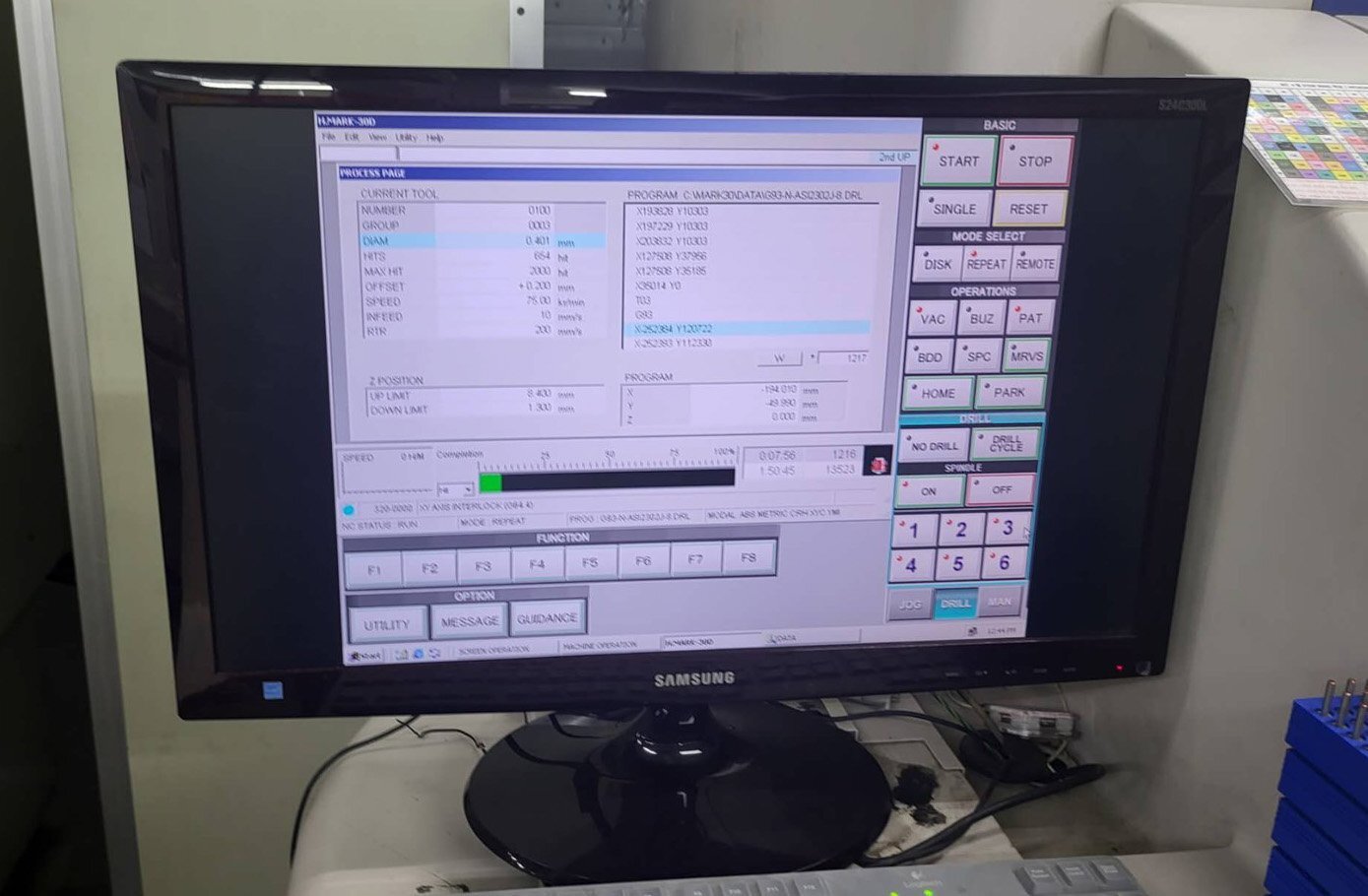

CNC Controller: H-Mark-30D

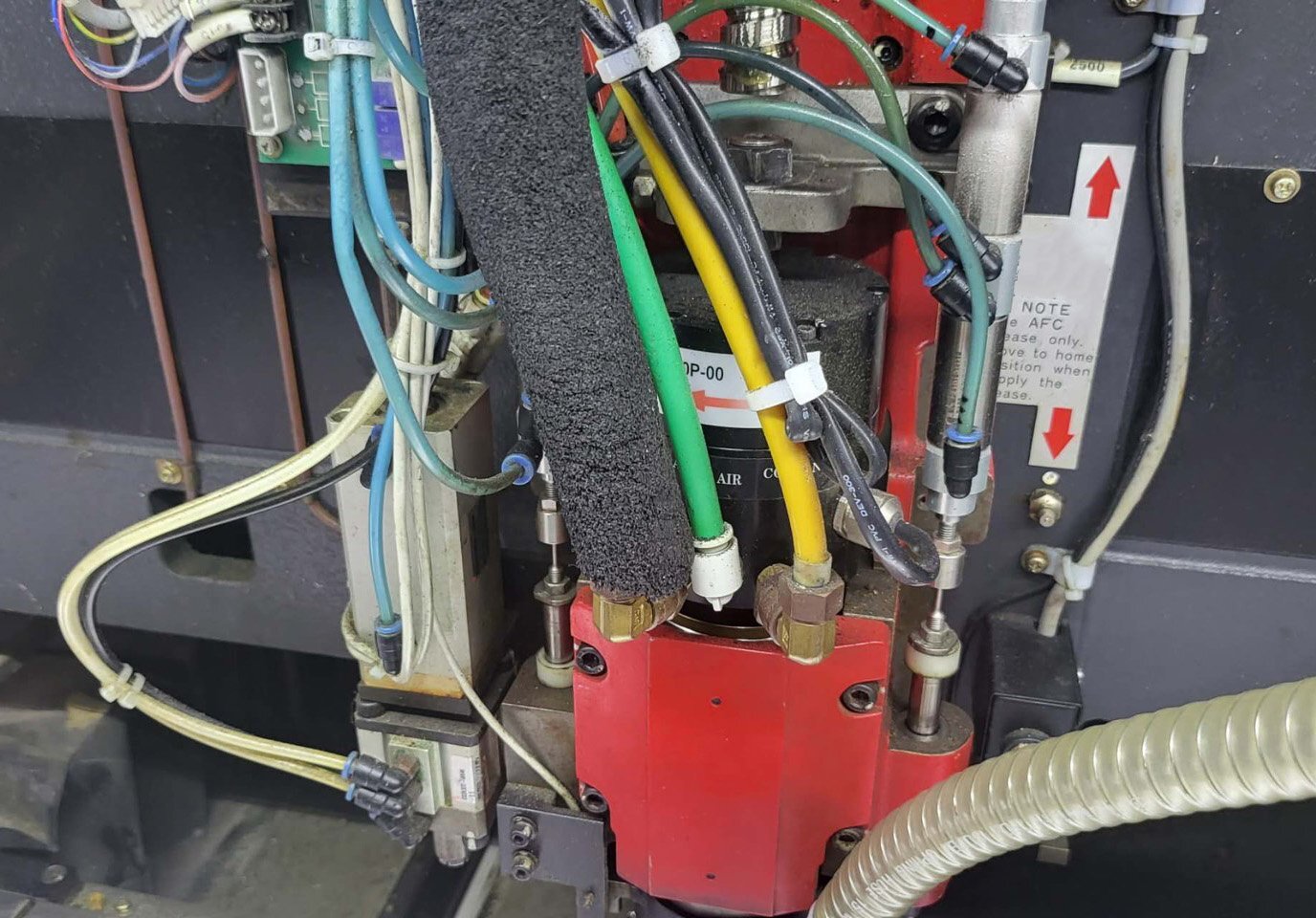

Spindle: H920B

2004 vintage.

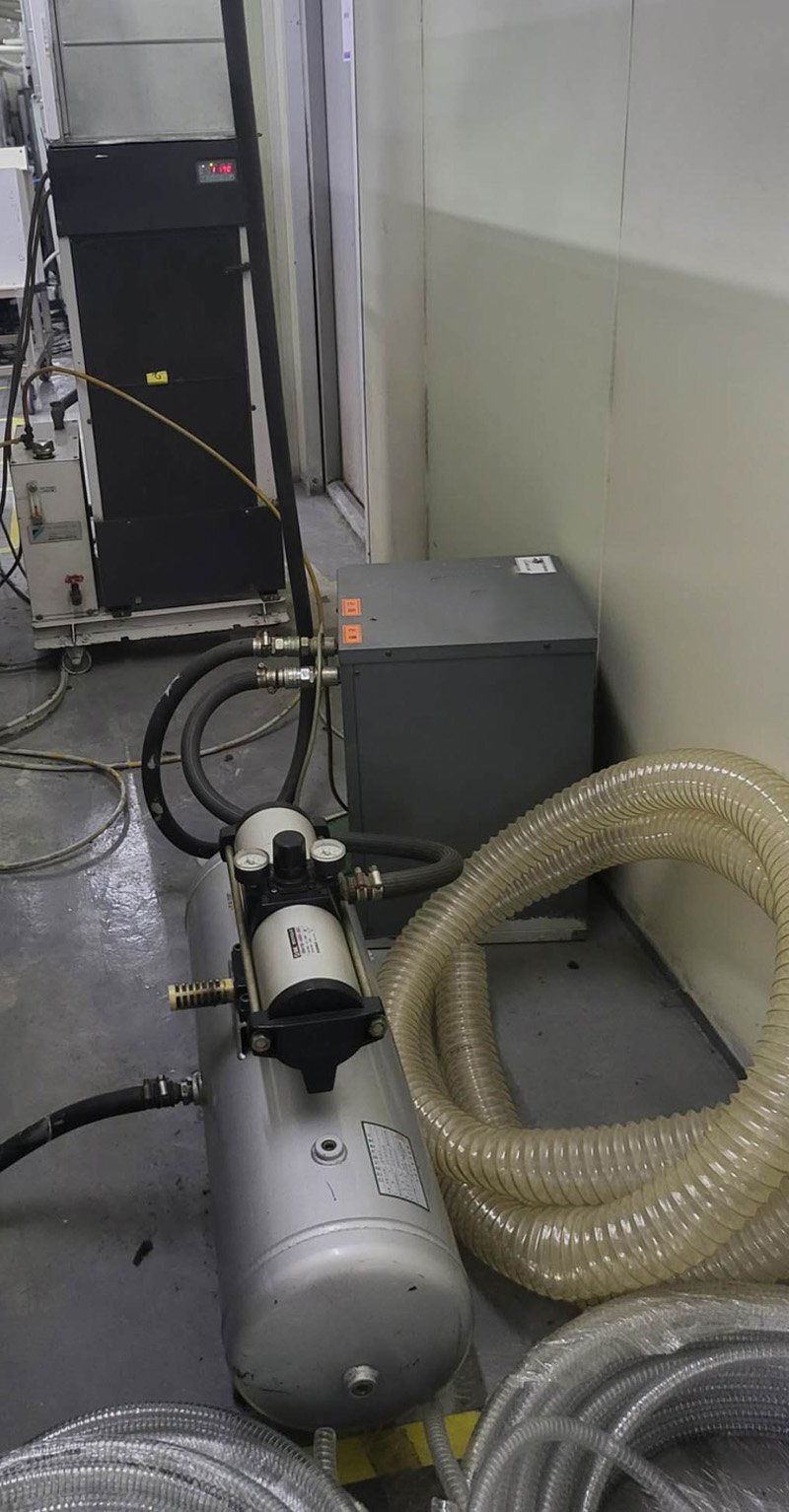

HITACHI ND-6N210E is a 3 axis vertical machining center with a maximum cutting speed of 8,000rpm. It features a spindle speed of 8,000rpm, rapid traverse speed of 19.3m/min, and a high-torque milling head for high cutting speed and reliability. The machine has a 7.5 KW spindle drive motor that provide high power and torque for higher cutting capacity. It is equipped with a 24 tool magazine for quick tool changes and increased productivity. ND-6N210E machine has Automatic Tool Changer (ATC) capabilities. The ATC allows for quick and automatic change of tools and faster machining cycles. It has a two-axis ATC system that includes seven-position arm and turret-type tool changer. The turret-type tool changer can hold up to twenty-four tools in an equal-length carousel. HITACHI ND-6N210E is also equipped with an Automatic Pallet Changer (APC). The APC allows for quick and easy loading and unloading of workpiece pallets directly into the work zone. The ATC and APC helps to increase machining efficiency. Other feed-rate control options are available for the X, Y, Z axes. These options include vector control, electronic step feed control, and manual pulse generator speeds. ND-6N210E has an advanced PC-based CNC controller with a graphical user interface. The color LCD display features easy to use programs and programming modes, as well as edit-on-the-fly capabilities. The onboard memory stores up to 25 programs, and 350 subprograms, which can be previewed on the LCD display. HITACHI ND-6N210E has two input methods available, these are RS232, and a USB port. The RS232 port is used for CNC programming and the USB port is used for downloading software and workpiece programs. The machine is equipped with multiple safety measures to ensure protection of operators and workpieces. ND-6N210E is ideal for a wide range of machining jobs, particularly for high-tolerance and complex parts. With its multi-axis capabilities and high cutting speed and torque, it is perfect for a variety of machining applications. It is a reliable and efficient machine that is ideal for manufactures and machining industries.

There are no reviews yet