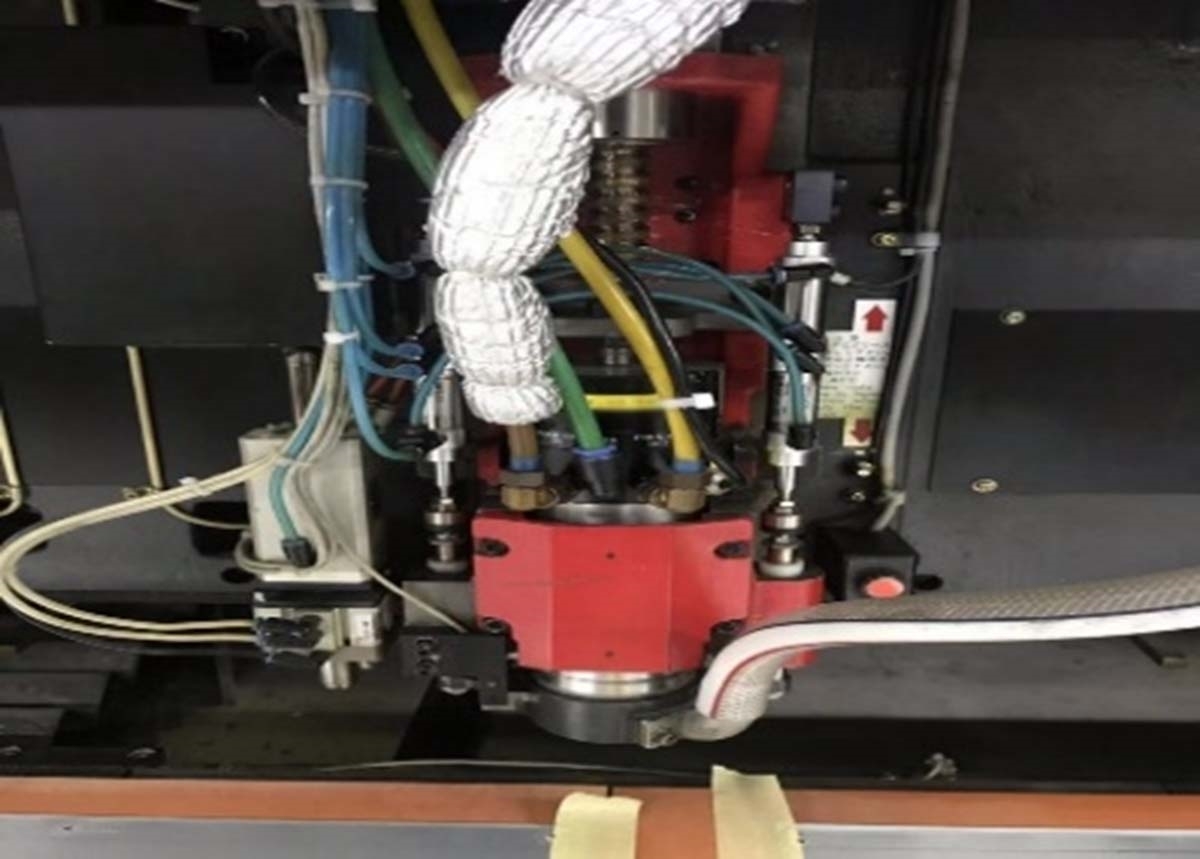

Used HITACHI ND-6N210E #9262748 for sale

URL successfully copied!

Tap to zoom

ID: 9262748

Vintage: 2003

Drilling machine

Table type: Pin clamp

Drilling area: 533 x 660

CNC Controller: H-Mark-30D (W2000)

Broken drill bit detector: Chip count

CCD Sensor (TP-D) diameter check

Spindle: H920E (200 Krpm) x (6) Assemblies (Bit shank 3.175 mm)

Air dryer: SMC (IDF22E-20-X156)

Oil cooler: AKZ568-D200B-1

Type: QIC

Power supply: 3 W, 220 V, 50/60 Hz, 15 kVA, 3 Phase

2003 vintage.

HITACHI ND-6N210E is a machine tool manufactured by HITACHI Seiki Co, Ltd. It is a versatile and reliable tool which offers a range of machining operations on a variety of metals. The tool is of high-performance, and is ideal for precision machining and cutting of metal components and parts. The tool has a machining capacity of 430 mm diameter and 600 mm length. It is constructed with a heavy-duty reinforced cast-iron frame, backed with vibration damping ribbing for an ideal working environment and better machining accuracy. The tool has a unique design which enables it to switch from vertical to horizontal in just a few minutes, allowing for versatility in its uses. The machining operations performed by ND-6N210E include turning, facing, drilling, boring, and end milling. It is equipped with a spindle system which supports both manual and CNC modes of operation. The spindle's rotation speed range is 40 to 4500 RPM, giving it the ability to produce small and large components with equal precision and speed. The machine is capable of high-speed drilling and cutting of metals due to its high-torque motor. It is also equipped with a spindle cooling system; this allows for increased accuracy of machining operations and better performance. HITACHI ND-6N210E comes with a Servo Generating motor with ball screws on all axes. It also features a control box which enables different settings and operations to be carried out; these settings can be adjusted via a 15-inch, full-color LCD touch panel. It also has a PLC for data storage and automatic program management. In order to ensure maximum machining accuracy, ND-6N210E is equipped with a wide range of quality control systems. These include slide position control, a two-way level slide position control, and a spindle speed variation monitor. Also, high-precision sensors are used to monitor the accuracy and details of machined parts. HITACHI ND-6N210E is a premium quality tool that operates both horizontally and vertically, allowing for both precise and reliable machining operation of metals. By utilizing its spindle system and advanced control interface, it can achieve highly accurate results in a number of different machining operations. The machine is designed to be energy-efficient, and its long-lasting performance makes it a dependable tool that can handle different machining applications.

There are no reviews yet