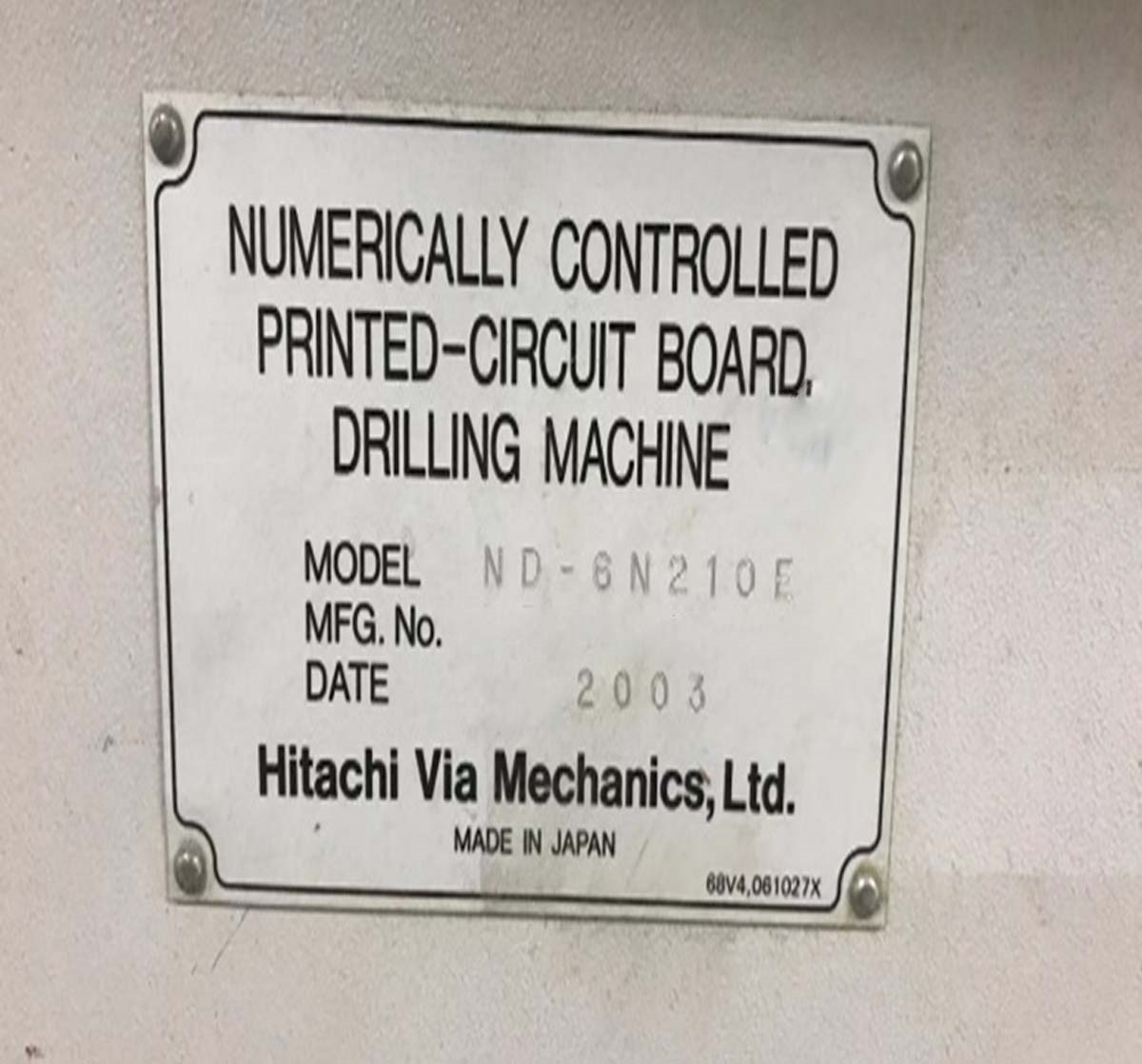

Used HITACHI ND-6N210E #9262755 for sale

URL successfully copied!

Tap to zoom

ID: 9262755

Vintage: 2003

Drilling machine

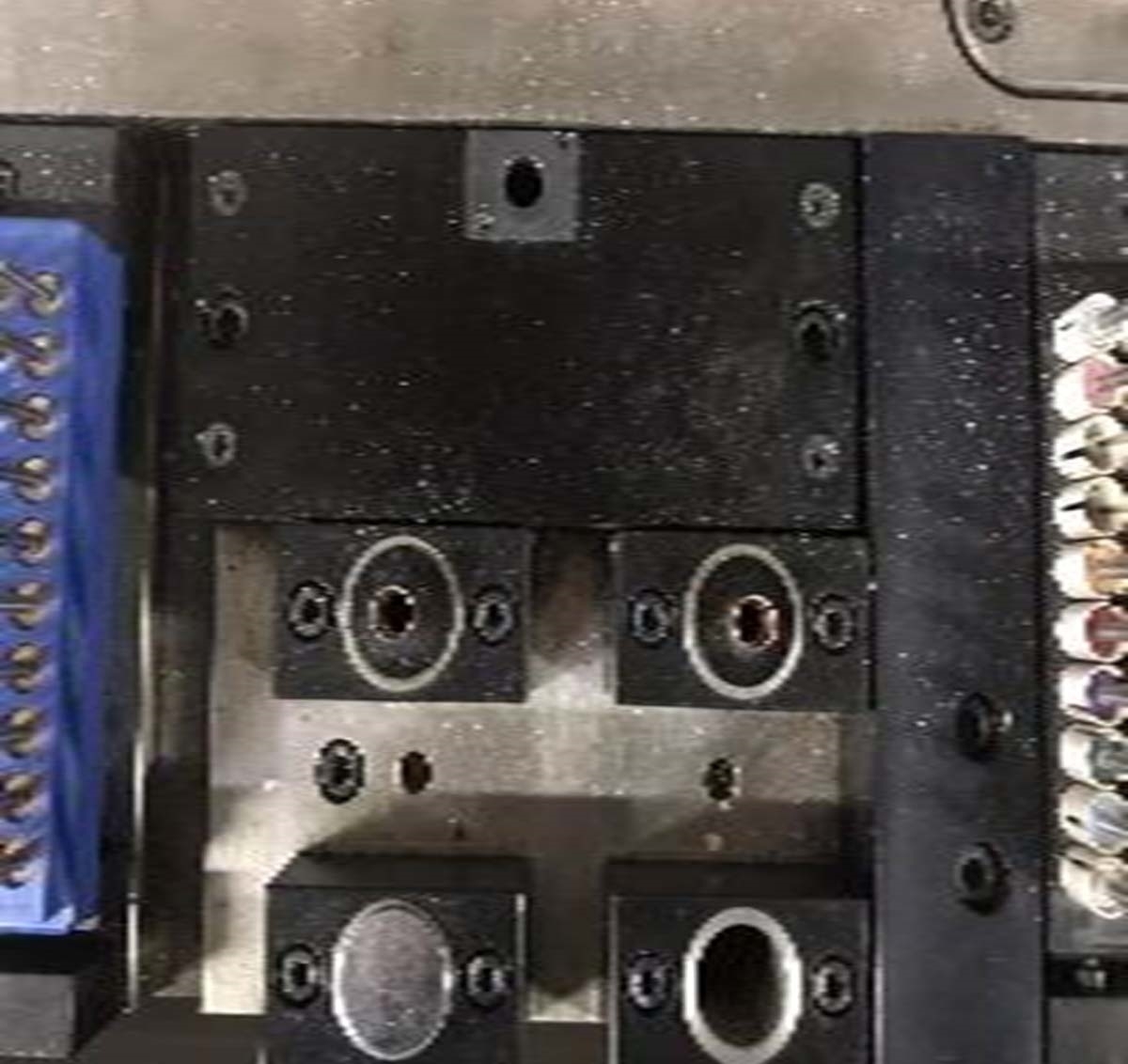

Table type: Pin clamp

Drilling area: 533 x 660

CNC Controller: H-Mark-30D (W2000)

Broken drill bit detector: Chip count

CCD Sensor (TP-D) diameter check

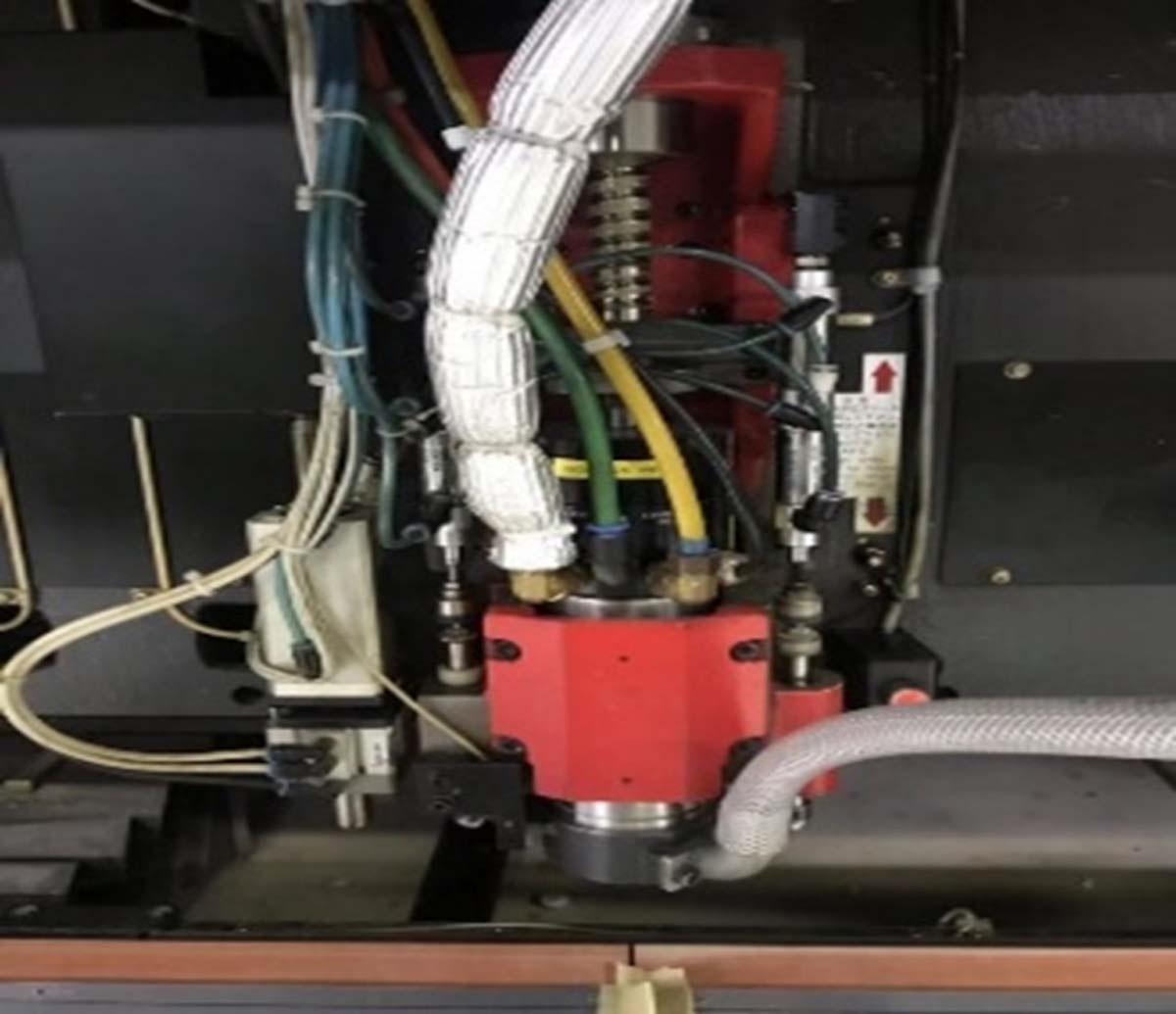

Spindle: H920B (200 Krpm) x (6) Assys (Bit shank 3.175 mm)

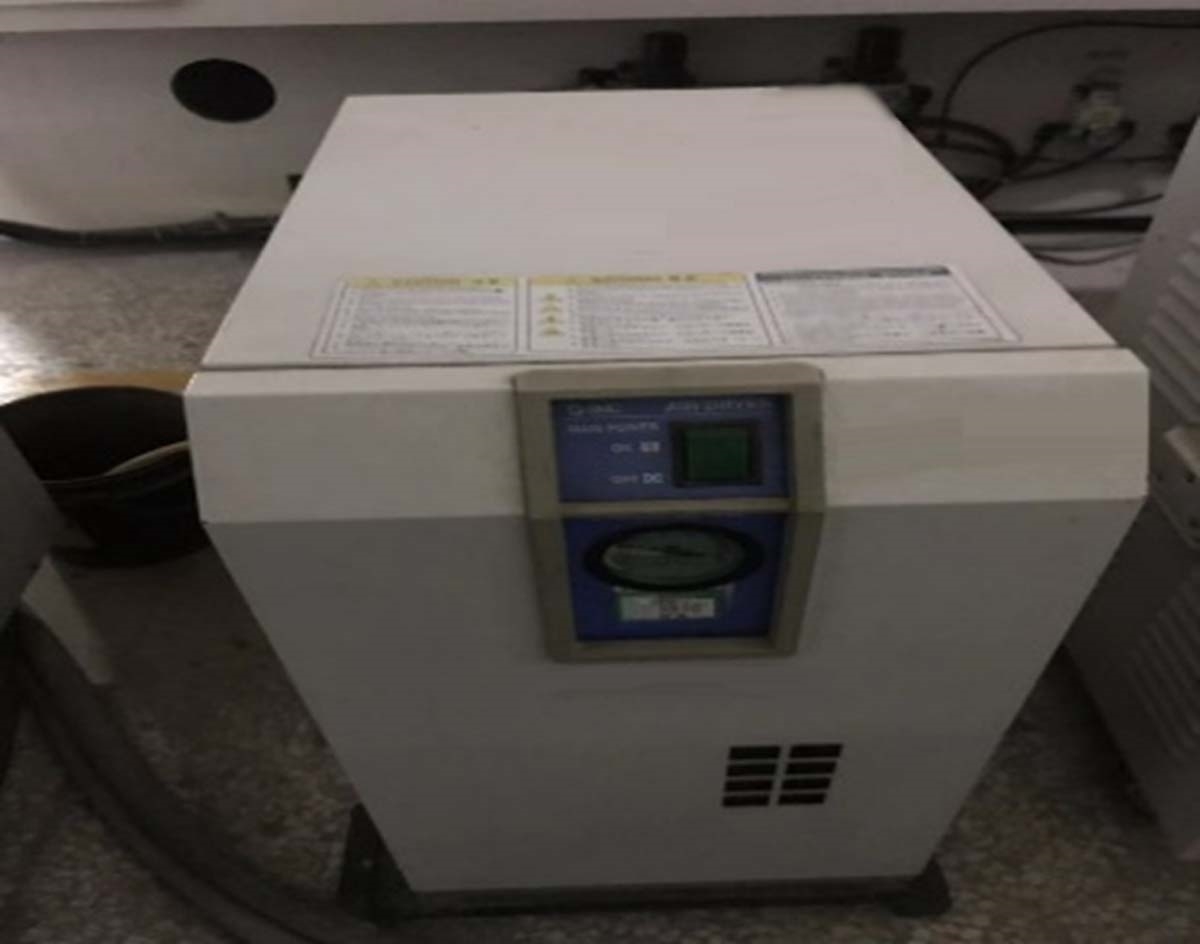

Air dryer: SMC (IDF22E-20-X156)

Oil cooler: AKZ568-D200B-1

Type: QIC

Power supply: 3 W, 220 V, 50/60 Hz, 15 kVA, 3 Phase

2003 vintage.

HITACHI ND-6N210E is a small machine-tool designed to produce parts accurately and efficiently. It is part of HITACHI ECOCÊND family of machining centers. This equipment is designed for industrial use and features a wide range of technologies that help improve accuracy and productivity. ND-6N210E is an X-Y-Z 3-axis machining center designed to perform multiple operations, such as milling, drilling, reaming, as well as tapping and threading. It is equipped with a manual or power feed spindle head for continuous rotational movement around three axes. It is capable of performing precise cuts on complex jobs and tough materials. This machining center has a direct-drive feed equipment that ensures smooth and quick operation. It also features a reliable servo motor which provides powerful performance. The dynamic control system ensures precise acceleration and deceleration, so that the machine runs smoothly and accurately. This unit also helps reduce vibration while cutting, resulting in improved accuracy and reduced tool wear. HITACHI ND-6N210E has a working envelope of 600 mm in the X directions, 400 mm in the Y directions, and 240 mm in the Z directions; its maximum spindle speed is 8000rpm. It is also equipped with an MT4 spindle taper, and a spindle motor of 1.5kW for high power and speed. The 7-position automatic tool changer allows for quick changeover of tools for flexible machining. ND-6N210E is designed to be easy to use, and it features a digital man-machine interface that provides operators with an easy way to control the machine. Its intuitive MPP (Machine Programming Panel) allows for easy programming of parts and commands. The panel also features a full memory of up to 600 profile and 100 part patterns for fast recall and repeat machining. Additionally, it also includes an automatic tool setting machine for precise measuring of tools. HITACHI ND-6N210E also includes detailed safety features. Its enclosed chamber and interlocked guards reduce the risk of injury, while anti-vibration technology and noise reduction reduce operator fatigue. ND-6N210E is a powerful and versatile machining center designed to produce parts accurately and with high precision. Its simple yet full-featured design and user-friendly control panel make it an ideal choice for the manufacturing of small products with tight tolerances.

There are no reviews yet