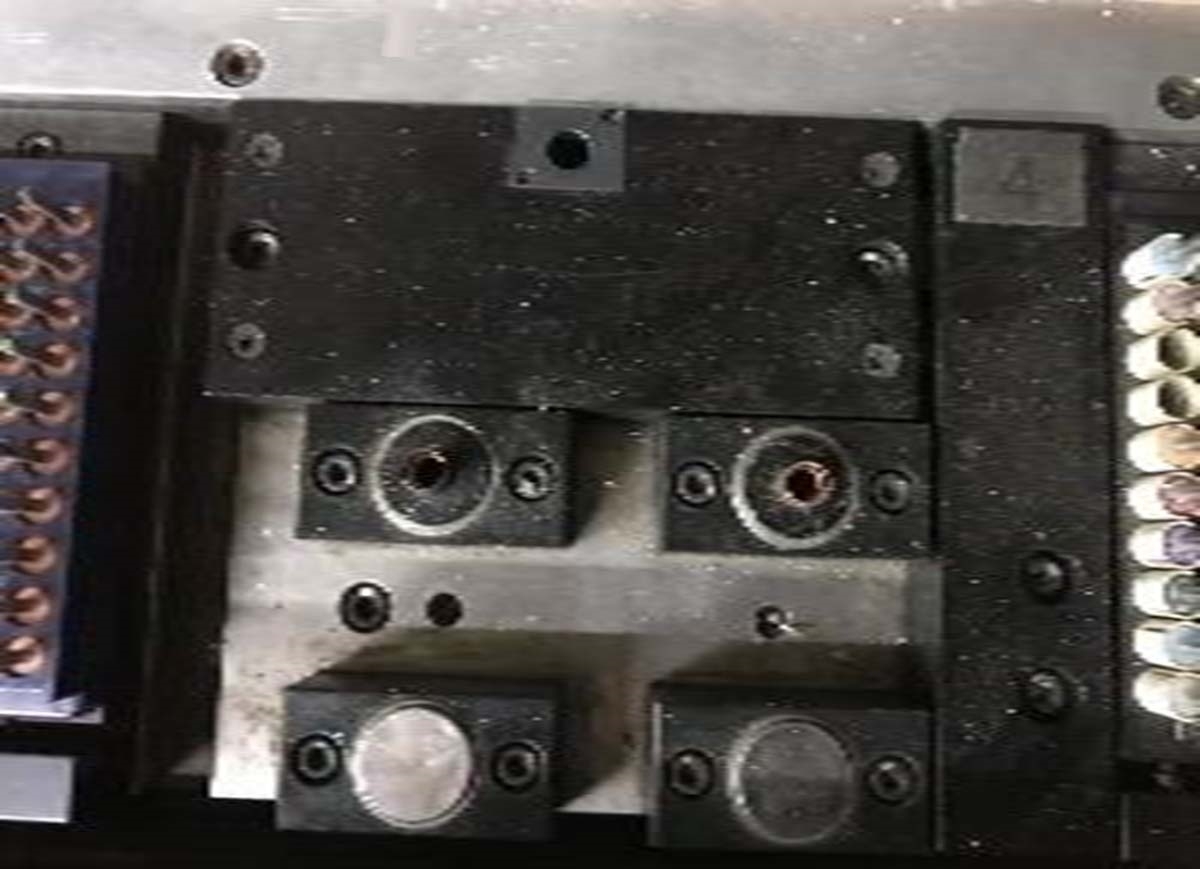

Used HITACHI ND-6Ne210E #9262759 for sale

URL successfully copied!

Tap to zoom

ID: 9262759

Vintage: 2005

Drilling machine

Table type: Pin clamp

Drilling area: 533 x 660

CNC Controller: H-Mark-30D (W2000)

Broken drill bit detector: Chip count

CCD Sensor (TP-D) diameter check

Spindle: H920B (200 Krpm) x (6) Assys (Bit shank 3.175 mm)

Air dryer: SMC (IDF22E-20-X156)

Oil cooler: AKZ568-D200B-1

Type: QIC

Power supply: 3 W, 220 V, 50/60 Hz, 15 kVA, 3 Phase

2005 vintage.

HITACHI ND-6Ne210E machine tool is a high-speed, double-column, vertical spindle CNC machining center. Featuring a highly rigid box swinging construction, ND-6Ne210E is designed for precise and efficient machining of difficult material such as titanium and aluminum alloys. The powerful 13-kW spindle motor enables a maximum spindle speed of up to 18000 rpm. With a table size of 2250mm (88.9in) and a stroke of 3300 mm (130.2 in) along X and Y axes respectively, this machine tool is suitable for efficient operations in the aerospace and automotive industry. Equipped with a cooling equipment and a 132-kW LSI numerical control, HITACHI ND-6Ne210E delivers high performance and outstanding positioning accuracy. The LSI numerical control features functions such as combined thread tapping and interpolated corner and curve movement. Its functions further enhance the machine's overall efficiency. To maintain a consistently high accuracy, the ND-6Ne220E is equipped with four high-rigidity ball-screws and is supported by a state-of-the-art electronic control system. This power unit helps to self-diagnose errors and deliver high output during operation. The use of an air curtain that automatically covers the saddle and column area prevents dirt and dust from entering the inside of the machine. This convenient feature helps to guarantee the accuracy and functional reliability of ND-6Ne210E during operation. HITACHI ND-6Ne210E utilizes a switching valve-type grease lubrication machine to ensure that oil reaches all parts of the machine. The oil is pumped from a separate reservoir into the headstock and the spindle to ensure its proper lubrication. A semi-closed oil circuit is employed to prevent oxidation and to minimize its consumption. ND-6Ne210E is designed to operate in extremely demanding machining conditions. As such, it is equipped with an advanced control tool to manage the machine's dynamic behavior. It also features an enhanced detection asset that monitors the real-time status of the machine's axes, temperature and air pressure, in addition to its positioning accuracy. Finally, HITACHI ND-6Ne210E is housed in a well-structured framework to protect the machine from unnecessary external vibrations and shocks. This stable structure ensures a high-level accuracy and the longevity of the machine tool. This machine tool is an ideal choice for demanding machining applications that require a high-level of accuracy and optimum performance. Combining precision and power, ND-6Ne210E is an efficient and reliable machine tool.

There are no reviews yet