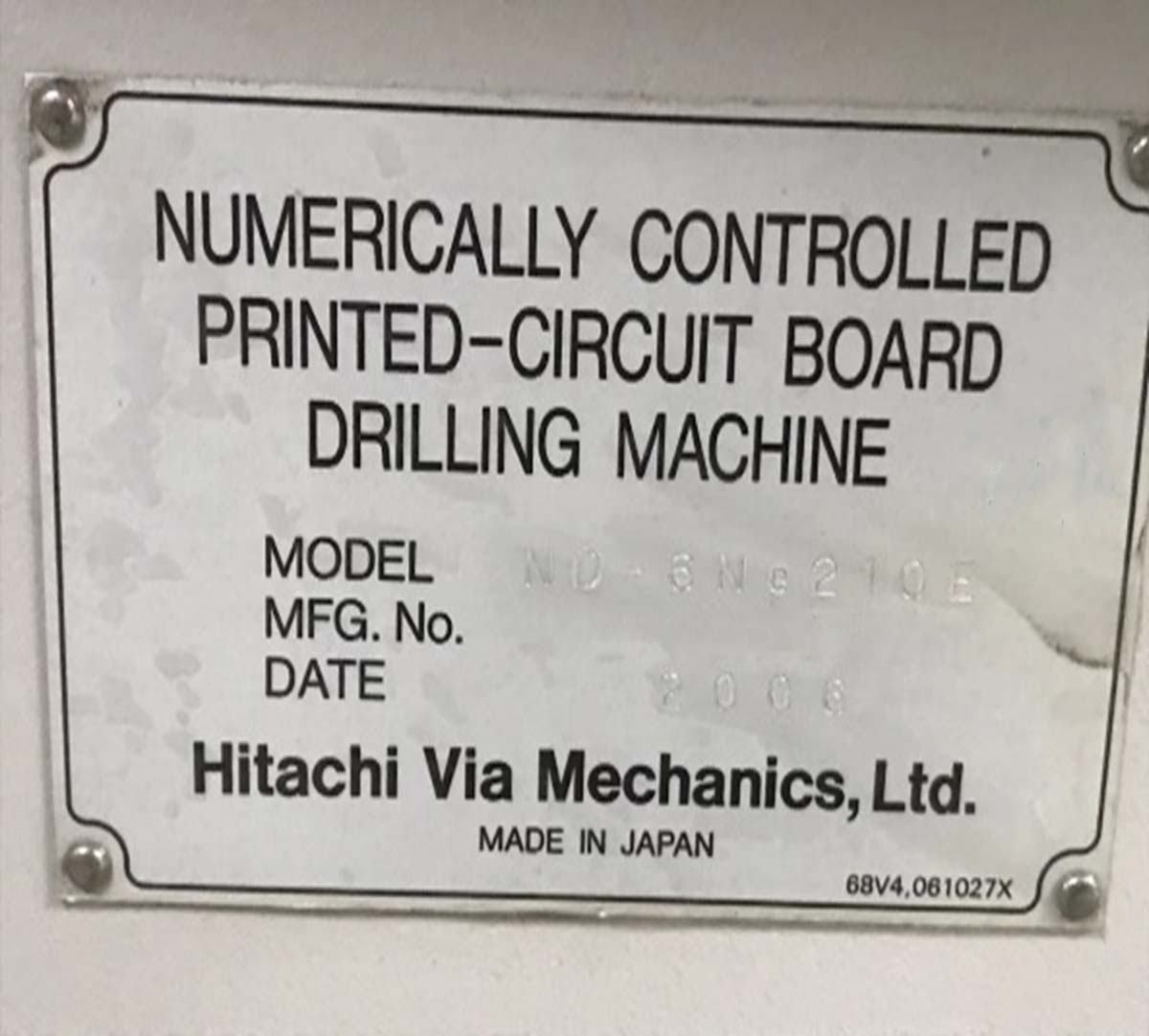

Used HITACHI ND-6Ne210E #9262825 for sale

URL successfully copied!

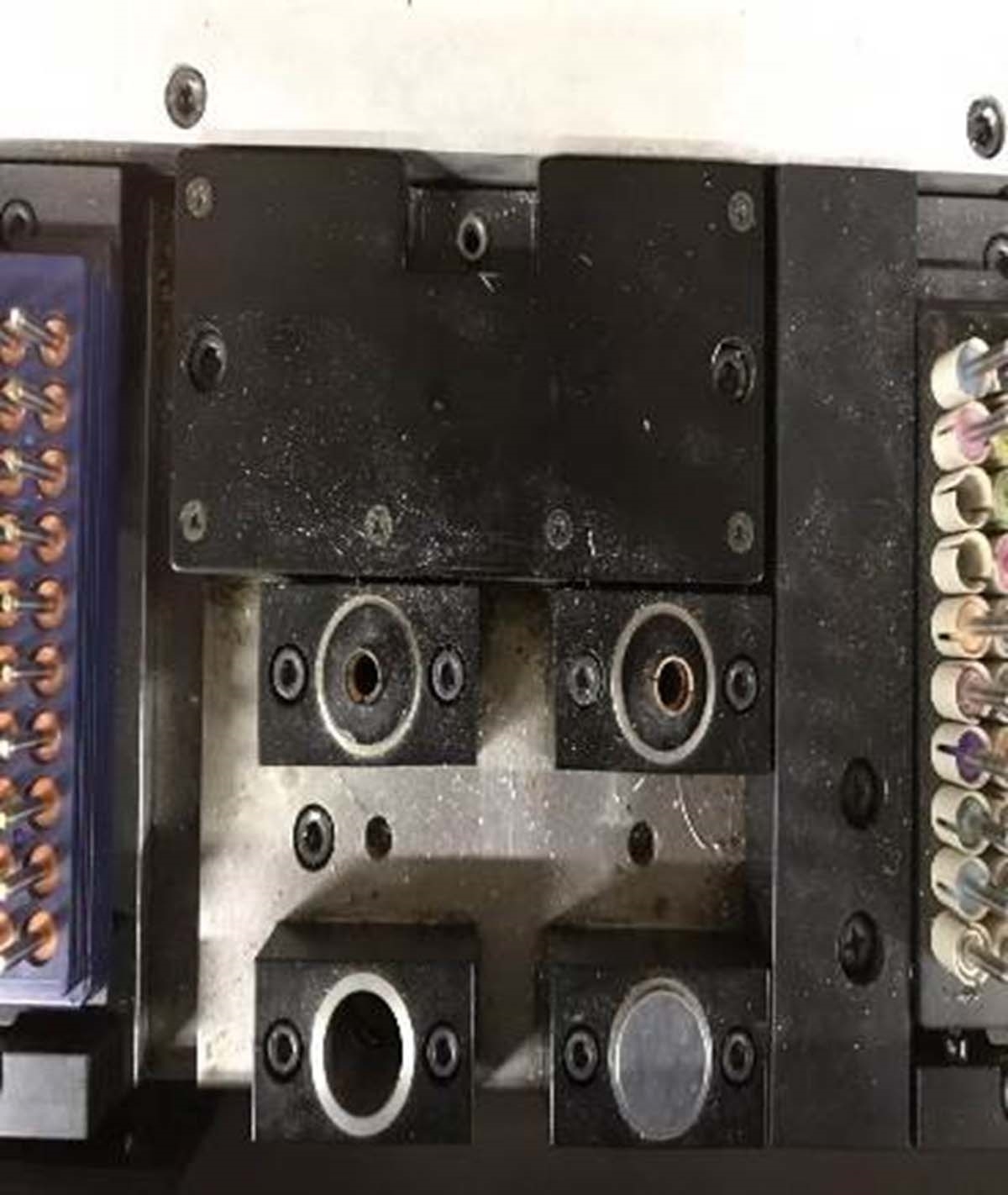

Tap to zoom

ID: 9262825

Vintage: 2006

Drilling machine

Table type: Pin clamp

Drilling area: 533 x 660

CNC Controller: H-Mark-30D (W2000)

Broken drill bit detector: Chip count

CCD Sensor (OP-TS4) diameter check

Spindle: H920B (200 Krpm) x 6 Assys (Bit shank 3.175 mm)

Air dryer: SMC (IDF22E-20-X156)

Oil cooler: AKZ568-D200B-1

Type: QIC

Power supply: 3 W, 220 V, 50/60 Hz, 15 kVA, 3 Phase

2006 vintage.

HITACHI ND-6Ne210E is an automated, CNC-controlled machine tool designed for high precision and increased throughput. It has a C-frame design, 12.6" x 10.6" (variant ND-6Ne220E) or 15.7" x 12.9" (variant ND-6Ne230E) worktable, 12,000-rpm spindle, 12 station automatic tool changer, and fanuc 0i-MD control. The C-frame design is the most common machine-tool configuration and provides a variety of clamping options to secure the workpiece. The table accommodates workpiece sizes up to 300mm (11.8″) in diameter and provides a range to facilitate multiple applications. The 12,000-rpm spindle provides smooth, high-speed operation, allowing for more productive machining processes. The 12 station automatic tool changer allows for quick and precise tool selection to increase production rates and reduce cycle times. The fanuc 0i-MD control facilitates user-friendly programming with its conversational user interface. It features excellent cutting performance, increased machine stability, greater flexibility, and improved throughput. The control also includes an advanced diagnostic system, ensuring system safety and diagnostic accuracy. ND-6Ne210E has a wide range of application flexibility, allowing for a variety of machining processes with multiple operations such as drilling, reaming, tapping, etc. It is suitable for parts with a range of sizes and shapes, making it suitable for a range of manufacturing needs. It can be used for general manufacturing, prototyping, and production of intricate parts with close tolerances. This machine tool is designed for maximum performance and precision. It utilizes a rigid construction to reduce thermal distortion and provide accuracy and repeatability. The re-circulating ball screw and linear motors provide smooth, precise motion and minimal backlash for accurate positioning. Ultimately, HITACHI ND-6Ne210E is a high-precision, automated machine tool designed for increased productivity. Its rigid construction and advanced control system provide accuracy and repeatability while its fanuc 0i-MD control is user-friendly and feature-rich. Its wide range of applications allows for a variety of machining processes and its 12 station automatic tool changer allows for rapid tool selection.

There are no reviews yet