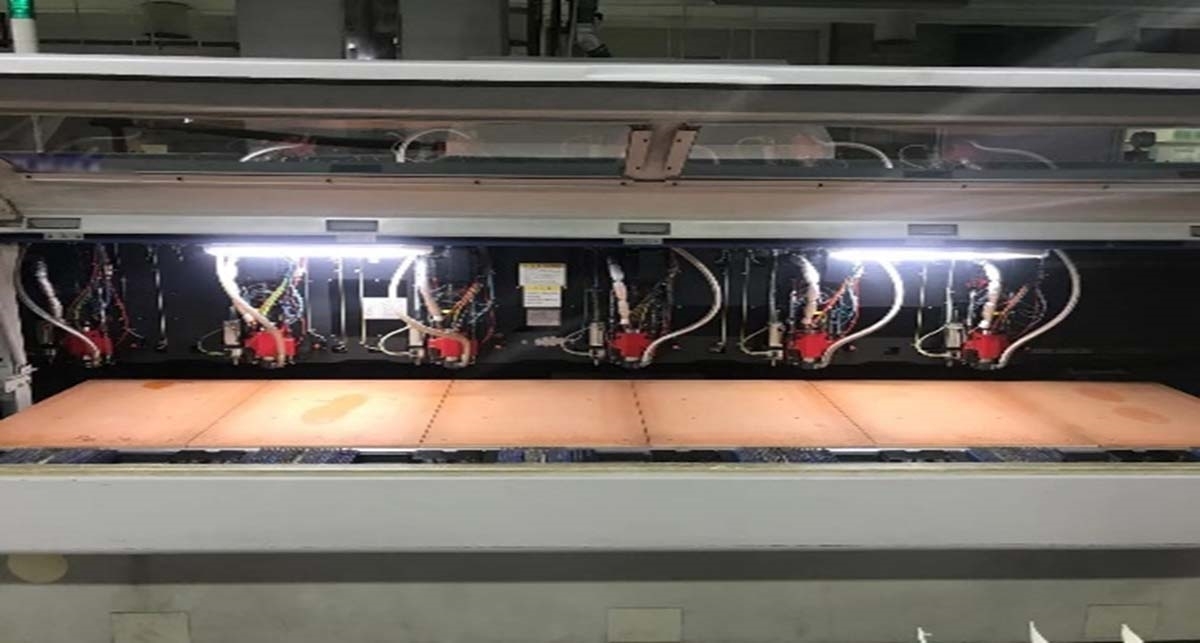

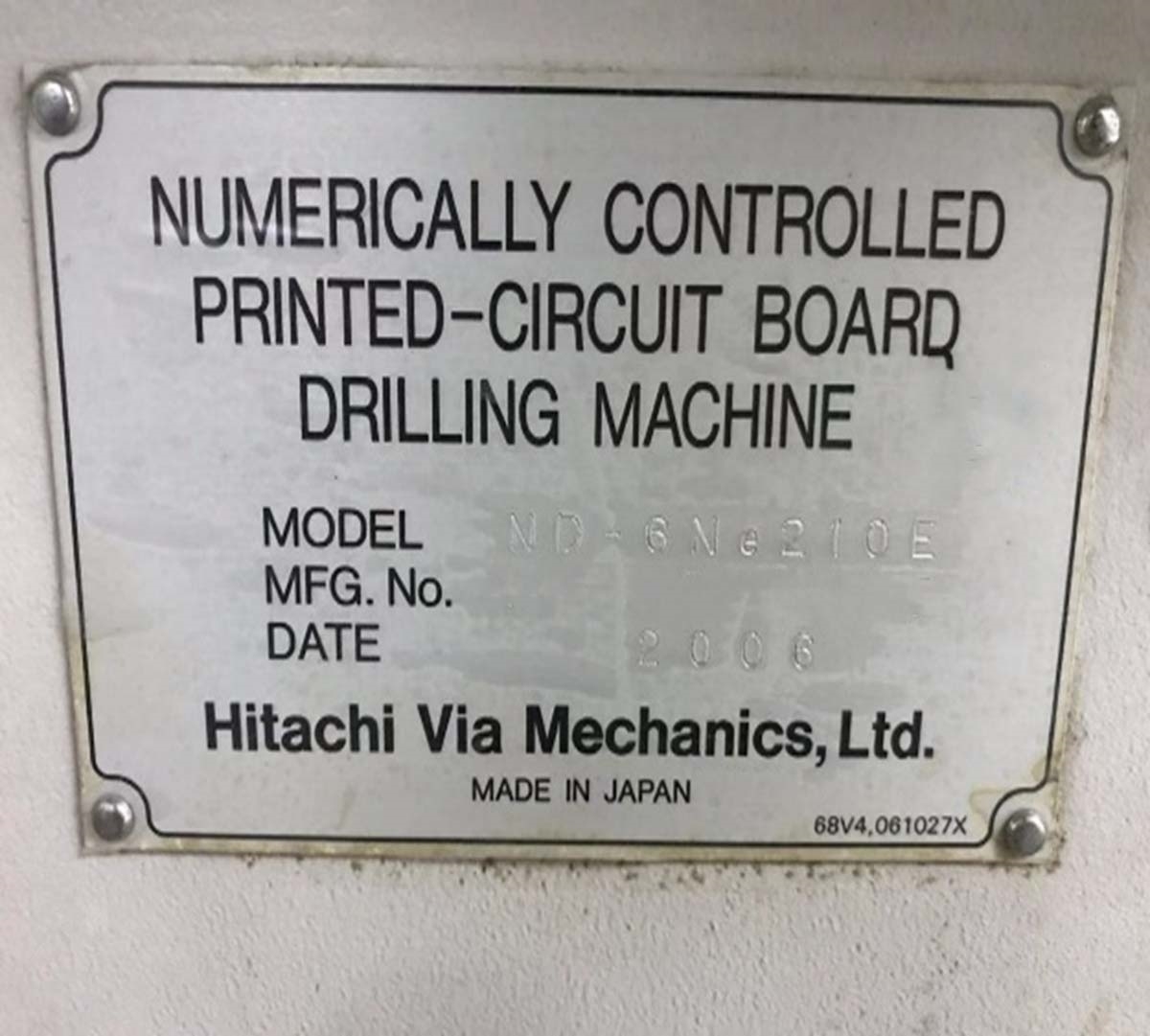

Used HITACHI ND-6Ne210E #9262832 for sale

URL successfully copied!

Tap to zoom

ID: 9262832

Vintage: 2006

Drilling machine

Table type: Pin clamp

Drilling area: 533 x 660

CNC Controller: H-Mark-30D (W2000)

Broken drill bit detector: Chip count

CCD Sensor (OP-TS4) diameter check

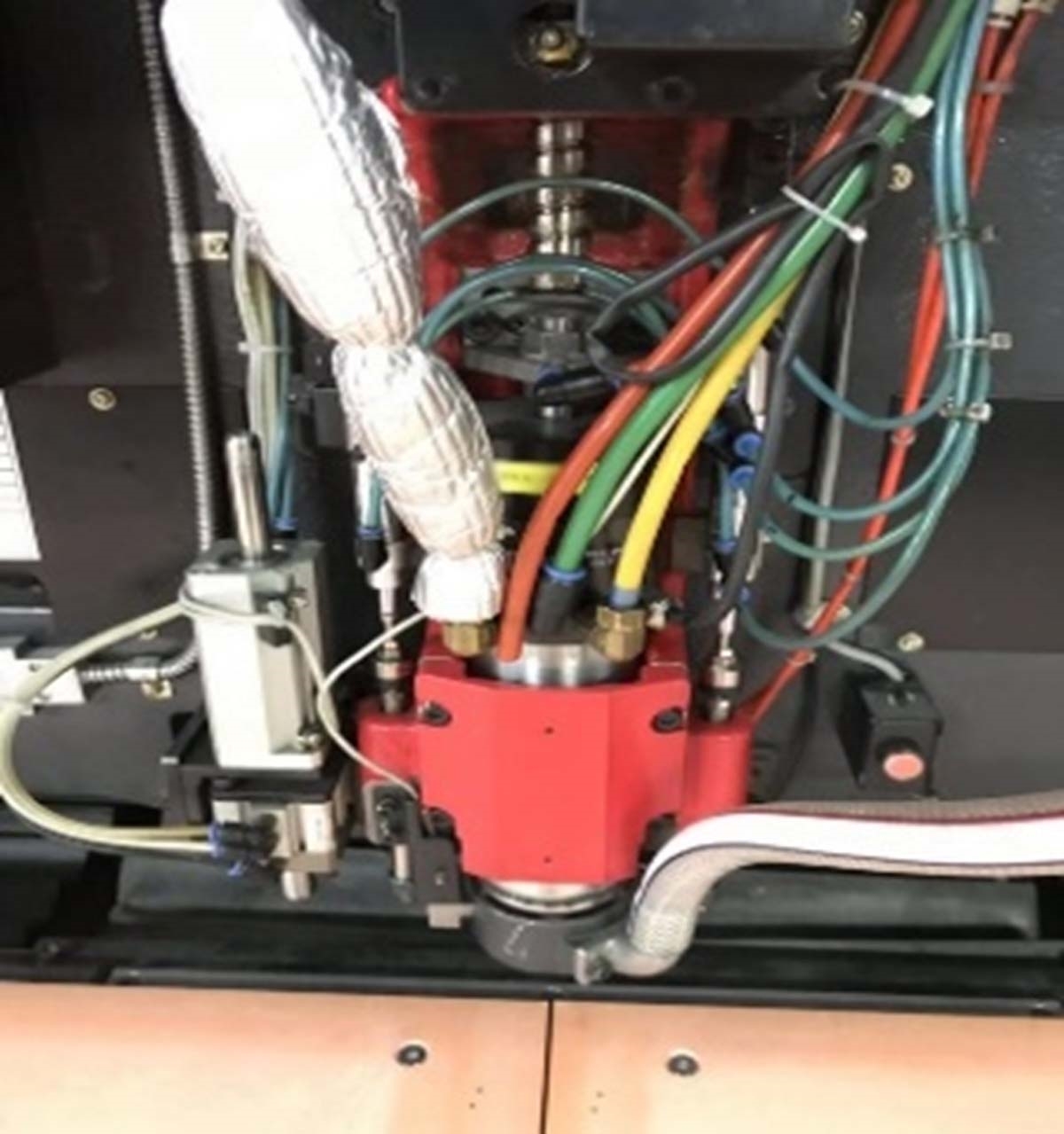

Spindle: H920B (200 Krpm) x (6) Assys (Bit shank 3.175 mm)

Air dryer: SMC (IDF22E-20-X156)

Oil cooler: AKZ568-D200B-1

Type: QIC

Power supply: 3 W, 220 V, 50/60 Hz, 15 kVA, 3 Phase

2006 vintage.

HITACHI ND-6Ne210E is a highly accurate and reliable machine tool that is designed for small to medium-sized parts. It is a 4-axis CNC machining center that uses the compact and rigid linear motor as the main driving mechanism. ND-6Ne210E features a linear motor and rotational servo control that enable it to perform high speed, highly accurate pressure & cutting machining of a variety of materials. It is equipped with a 20,000rpm built-in spindle and a high-precision tapping drive, equipped to 1/100 micro grade automata technology, making it the perfect choice for high level accuracy with high-precision results. HITACHI ND-6Ne210E is a highly productive machine tool, which can perform various machining operations such as milling, drilling, tapping and external thread cutting with a quick response time and high precision. It is equipped with a 0.0001mm resolution on its position control, which enables it to be highly accurate and reliable in its machining performance. Its built-in chip discharging device allows it to dispose chips automatically, drastically improving the efficiency of the machining process. ND-6Ne210E also features an NC control screen and a conversational panel. The NC control screen has a program setup function, which allows the user to check the parts program in a graphical format, as well as setting up programs. This not only saves time and labour, but also helps to improve accuracy and reliability in the program. In addition, HITACHI ND-6Ne210E features an adapter for operations such as drilling and reaming, in order to improve the machining performance. It is highly customizable, and its main spindle motor can be selected between 3.7 [kW] and 5.5 [kW], with a variety of optional spindle motors also available upon request. ND-6Ne210E is equipped with a wide range of safety features, such as a dust detection sensor, when large dust levels are present, this sensor will detect and trigger an alarm to alert the user of the presence of potentially hazardous dust and fumes. It is also equipped with overload control, which stops the machine if an overload occurs. This helps to protect the machine from potential damage and allows the user to perform maintenance on it. Overall, HITACHI ND-6Ne210E is an ideal choice for those looking for a reliable and highly accurate machine tool. It delivers a high speed and accuracy, as well as a maximum level of safety and control for its user. With its compact size and its ability to process a variety of materials, ND-6Ne210E is the perfect choice for small to medium-sized parts.

There are no reviews yet