Used HITACHI SEIKI CS 25 #9003178 for sale

URL successfully copied!

Tap to zoom

ID: 9003178

Vertical CNC lathe

Capacity

Table diameter: 10"

Max swing: 15.7"

Max height under rail: 14.6"

Spindle

Min speed: 30 rpm

Max speed: 4,000 rpm

Motor: 25 HP

Spindle nose: A2-8

Diameter of thru hole: 3.1"

Bearing inside diameter: 5.1"

Heads: (1) head, (12) turret heads

Travel: X-axis: 15.5", Z-axis: 14.6"

Feed rate of X and Y-axis: 1181 IPM

Turret head

Shank size of O.D. tool: 1"

Boring bar size: 1 1/4"

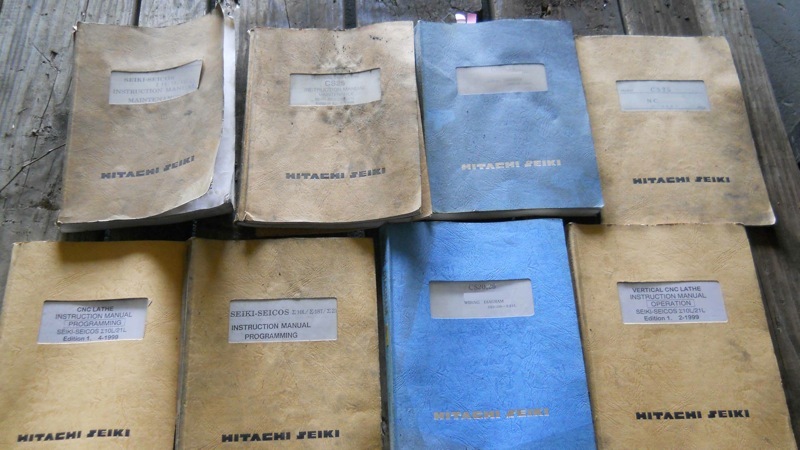

Seicos 21L/CRT CNC Control

Pick and place spindle system

Chip conveyor

RS-232 interface

Transformer

Coolant system.

HITACHI SEIKI CS 25 is a large-size machine tool that is utilized to carry out complex machining operations with precision. It is an ideal choice for tool and die makers, job shops, as well as larger production applications in the automotive and aerospace industries. CS 25 model features a highly rigid frame, with a robust TSC headstock and tailstock. The machine is powered by an AC servo milling motor, and makes use of built-in functions in the form of machining strategies, enabling economical cutting with no chatter on large work pieces. The machine turret, equipped with a standard 8-tool capacity, is driven by a powerful 15 HP AC spindle motor. This allows for high speed machining, as well as precision finish machining. HITACHI SEIKI CS 25 also features a tool life monitoring system, enabling the operator to program the machine to make the most efficient use of the tools in use. CS 25 is designed to provide users with maximum speed and reliability. As such, the machine is designed to provide minimal wear and maintenance in order to maximize productivity and cut down running costs. The machine further features a versatile tooling system allowing for a variety of cutting operations, including slotting, planing, rotary edge facing, drilling, tapping and boring. Moreover, HITACHI SEIKI CS 25 is built for simultaneous 4-axis machining, enabling the machine to perform highly complex operations such as contouring, helical machining, and tapered cutting. To ensure that the machine achieves maximum precision even at extremely high rotational speeds, the machine spindle is cooled using flood coolant, to ensure low temperature and minimal thermal deformation. CS 25 also features an automatic lubrication system which ensures that all parts and components are adequately lubricated for optimal functioning. The machine further includes a CNC controller, with a full range of conversational programming features, allowing for easy integration and operation of existing CAD/CAM software. To facilitate operator safety, HITACHI SEIKI CS 25 also features a lockable emergency stop and hand wheel control for manual operation. In conclusion, CS 25 is the perfect choice for large-scale machine tools, with a highly rigid frame, fast AC servo motor, and a variety of tooling and programming features. The machine offers excellent precision, even at high speeds, and is designed to provide minimal wear and maintenance.

There are no reviews yet