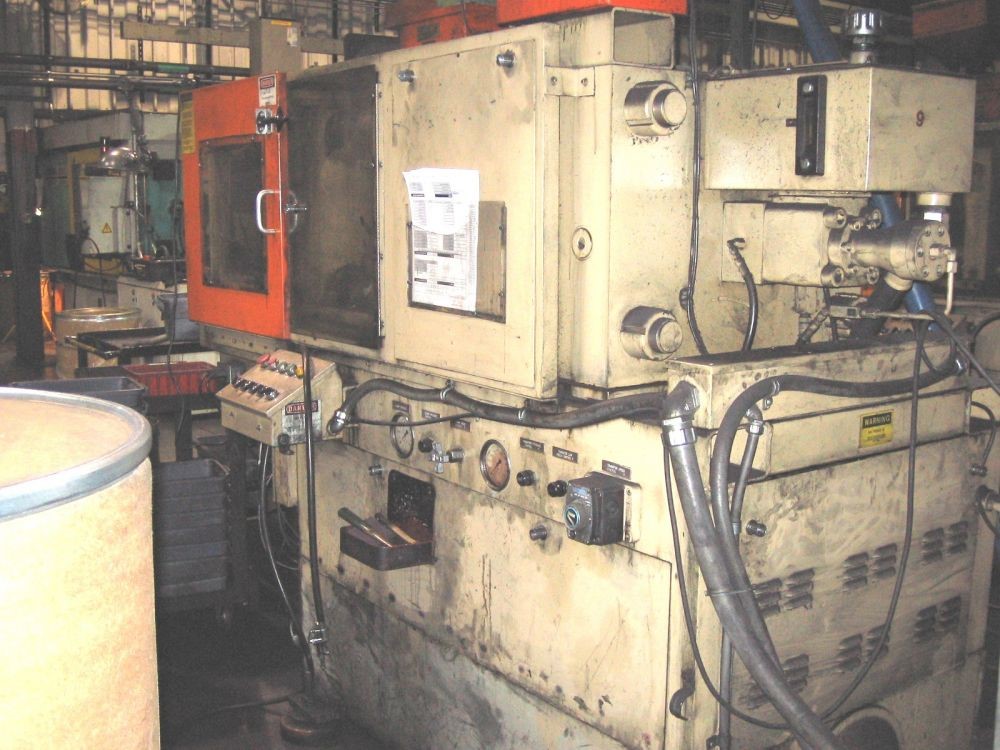

Used HULL TH100 #9114006 for sale

URL successfully copied!

Tap to zoom

ID: 9114006

Automatic Transfer Molding Machine

Hydraulic Ejector

Hopper

Pushbutton Controls for: Cull Knockoff; Feeder

Liquidaire Coolant System

Selector Switches for:

Man/Semi/Auto

Clamp Close/Open

Ejector Retract/Advance

Transfer Retract/Advance

Trans. Low On/Off

Tonnage Capacity – Clamp: 100 Tons

- Transfer:25 Tons

Stroke Length – Clamp: 10"

- Transfer:10"

- Hydraulic Ejector (Adj.): 0" – 3"

Daylight Opening: 20"

Die Space: 20" L-R x 20" F-B

Minimum Mold Height: 10"

Height to Platen Centerline: 52"

Working Pressure - Clamp: 2735 PSI

- Transfer:2545 PSI

Oil Reservoir Capacity: 90 Gallons

Clamping Speeds – Fast Close: 385" / Min.

- Pressing: 0" – 21" / Min.

- Returning: 542" / Min.

Transfer Speeds – Fast Close: 325" / Min.

- Pressing: 0" – 70" / Min.

- Returning: 388" / Min

1991 vintage.

HULL TH100 is a high-precision machine tool designed for precision machining applications. It is manufactured by HULL, a renowned provider of professional quality tools for metalworking and other industrial applications. TH100 is built for a wide variety of cutting applications ranging from small drill bits to larger end mills, countersinks, and thread mills. It has a full range of accessories for greater versatility and maximum production efficiency. It has a sturdy column-type design and a wide working area to ensure excellent accuracy and stability. HULL TH100 features a robust, rigid vertical hunting machine base with carbide-tipped, hardened and ground screws for stability and accuracy over the full range of travel. It is equipped with electronic overtravel and auto-shutoff for superior safety. The headstock can be adjusted by an adjustable stop screw, front-mounted double-spindle tailstock, and the spindle with adjustable depth stop. This allows for superior coordination of the machine centerline for easier and better setting-up of workpieces. TH100 is equipped with an 8-position automatic tool-positioning indexing system for quick and easy tool changing. Its precision-machined spindle features a universally-reversible spindle bore and it is designed to accept a wide range of taper tooling, from straight shank and long collet holders to a full range of universal quick-change collet chucks. The advanced motor and spindle design of HULL TH100 enable higher cutting capacities with removed shaped end mills, while offering multiple spindle speed options. It is also equipped with safety features, including a full-length door guard for maximum protection, and interlock switch to shut down the spindle motor in the event of a door or table opening. The front-mounted tailstock barrel and center can be swiveled in any direction for superior flexibility in machining operations. TH100 also features pre-programmed functions for semi-automatic operation that help reduce setup time and tool wear. HULL TH100 is perfect for machining small-to-medium parts and job-company production where precision, accuracy, and quality are top priorities. It requires minimal maintenance to stay reliable and hold its accuracy over multiple runs and long production times. Its versatility and ease of use make it an ideal choice for a wide range of machining operations.

There are no reviews yet