Used JOHNFORD VMC-1600S #9116602 for sale

URL successfully copied!

Tap to zoom

ID: 9116602

Vintage: 2006

CNC Vertical Machining Center

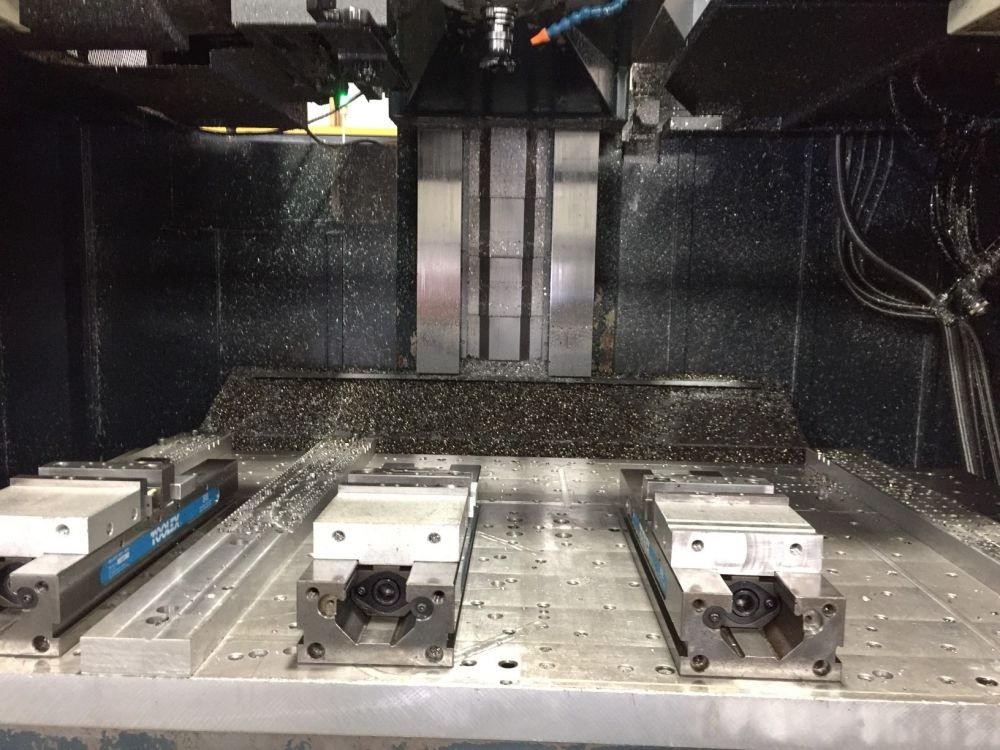

Working Surface of Table: 70.9" x 39.4"

Table Load Capacity: 2645 Lbs.

Travels: X-Axis: 63"; Y-Axis: 43.3"; Z-Axis: 31.5"

Distance Spindle Table Nose 6.7" – 38.2"

Distance Spindle C/L to Column: 45.3"

Rapid Traverse Rate: X- & Y-Axes 18M / Min.; Z-Axis: 12M / Min.

Spindle Speeds: 15,000 RPM

Spindle Taper: CAT 40

Spindle Feeds: 1mm – 12,000mm / Min.

Spindle Diameter: 2.75"

Spindle Motor: 15 / 10 HP 3/60

Maximum Tool Diameter: 4"

Maximum Tool Length: 12.5"

Maximum Tool Weight: 22 Lbs.

Fanuc 0i-MC CNC Controls

32-Position Automatic Tool Changer

Pallet Changer

Through-Spindle Coolant

4th-Axis Interface

Caterpillar Chip Conveyor

2006 vintage.

JOHNFORD VMC-1600S is a heavy-duty vertical machining center manufactured by JOHNFORD Machine Tool Company. This advanced machine tool is designed for heavy machining needs and can handle a variety of applications, such as high-speed machining, profile milling, boring, and drilling. VMC-1600S is equipped with a high-powered spindle mounted on a sturdy, rigid base. The spindle is powered by an 18.5 HP 4000 RPM motor and can generate up to 8,000 RPM. The spindle head can rotate a full 360 degrees in either direction and has a rapid traverse rate of 1250 IPM. The machine has an X-axis travel of 63" and a Y-axis travel of 30" with a Z-axis travel of 20". It can handle a maximum load of 1500 lbs. JOHNFORD VMC-1600S has a precision ground box-ways design and a recirculating ball screw design for excellent accuracy. An optional ATC version is also available. The standard control is a Fanuc OiMate CNC equipment, with a 10.4" color LCD monitor, keyboard and mouse input. The machine also comes with an automatic lubrication system, an electric cabinet, and a cooling unit with an air curtain as standard. VMC-1600S is a reliable and durable machine tool that can easily handle day-to-day operations. It has a large working envelope and provides a superior machining experience. The advanced control machine makes it suitable for complex tasks and allows for easy program editing and debugging. With its rigid construction and reliable components, it ensures consistent results and longer product life. This machine tool is perfect for small- and medium-sized shops and is designed to meet the needs of production and job shops.

There are no reviews yet