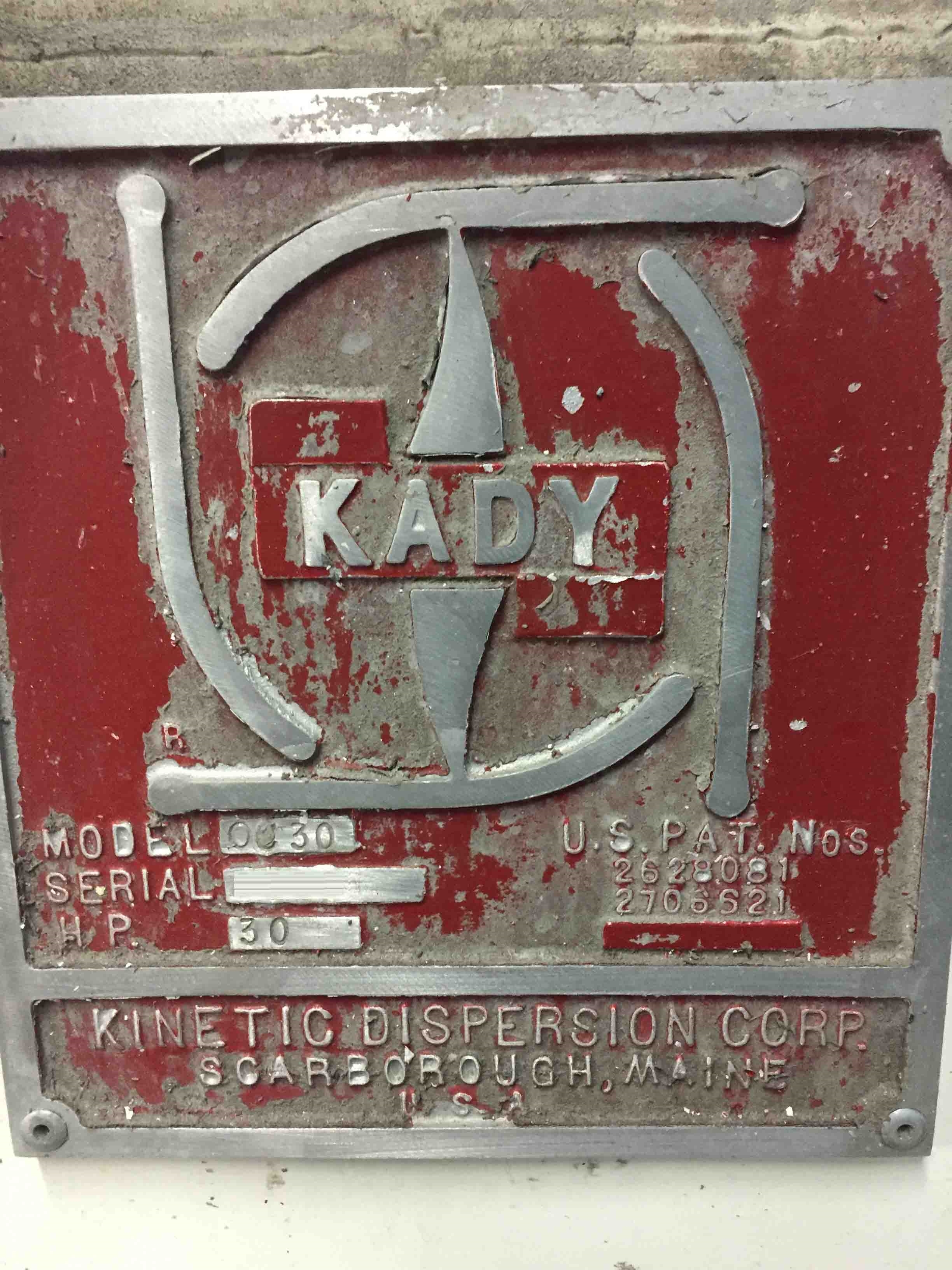

Used KADY OC 30 #9205112 for sale

URL successfully copied!

Tap to zoom

KADY OC 30 is a machine tool from KADY International Corporation that is designed for use in precision CNC machining applications. Specifically, it is a horizontal spindle universal CNC machine that features a conventional design. It is equipped with an accurate, direct-drive AC motor spindle and operates on a two-axis configuration. OC 30 was designed with a high-tolerance, low-warp spindle, offering superior accuracy and reliability. It employs an integrated cooling system to maintain optimum temperatures during machining operations, which decreases precision-tool failure and machine downtime. In addition, the machine is equipped with counterweights that prevent excessive vibration and increase stability. An array of sealed linear bearings and hardened ball screws are used to further improve accuracy, increasing tolerance to errors. KADY OC 30 comes with a full range of accessories for controlling and enhancing the machine's performance. The operator control panel provides access to the CNC system and allows for easy adjustment of various parameters, such as feed rates, spindle speed, and tool wear notification. Various options are available for OC 30 to ensure it can meet the needs of the user. It can be outfitted with an FANUC, Siemens, or Yaskawa CNC system, depending on the user's requirements. It also features a hardened bed construction, with integral Z-axis support and wide-sweep gear box. For spindle head attachment, KADY OC 30 utilizes high-precision serrated spindle couplings, allowing for rapid setup and precise tool machining. It also features an automatic tool changer, enabling the machine to process multiple tools without the need for manual adjustments or restocking. Additionally, the machine supports off-center drilling operations and comes with an integrated vacuum table for holding materials in place. OC 30 is suitable for a variety of materials, including stainless steel, aluminum, plastics, and composites. Its heavy-duty construction and superior accuracy make it an ideal solution for precision machining operations, such as automotive components, mold and die production, and general-manufacturing parts. Its flexibility and dependability make it an excellent addition to any company floor.

There are no reviews yet