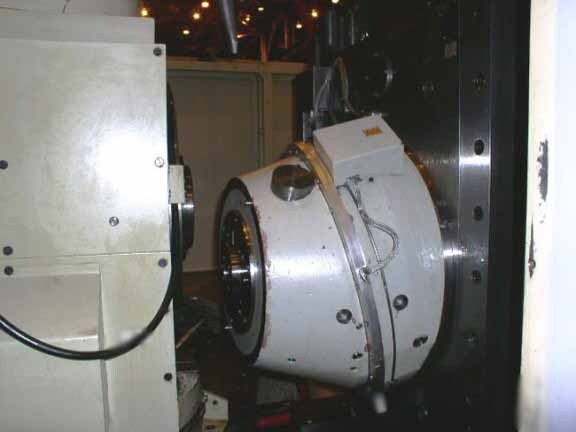

Used KLINGELNBERG S35 #9183654 for sale

URL successfully copied!

Tap to zoom

ID: 9183654

CNC Gear cutting machine

Specifications:

Max workpiece dia: 23.6"

Smallest normal module: 0.137"

Largest normal module: 0.393"

Max tooth width: 3.93"

Smallest transmission ratio: 1:1

Largest transmission ratio: 1:10

Spiral angle (Degrees): 0-60

Cutter head spindle:

Oerlikon short taper 1:4: 0-5.118"

Spindle speeds (Inf Var ): 30-350 min-1

Spindle tilt (Degrees): 0-35

Eccentricity: 0-10.82"

Cutter head radius: 3.46"-7.12"

Workpiece spindle:

Oerlikon outside taper 1:4: 0-8.85"

Inside taper no 39, 1:19,692: 6"

Max spindle speed: 0-160 min-1

Bore: 0-6.29"

Axial offset: +/-2.36"

Swivel range (Degrees): -7 up to 90

Feeds:

Generating feed (Inf Var): 40 Deg / Second

Equipped with:

Schleicher (Siemens) 10-Axis CNC with RS-232

11" Magnetic chip conveyor

Bosch drives

Continuous & Single indexing methods

AC Motors & controls

100 kVA Transformer

Chiller

Mist collector

Mclean air conditioner unit.

Klingelberg KLINGELNBERG S35 is a CNC-controlled four-axis machining center manufactured by the German machine tool manufacturer Klingelberg, renowned for their high quality and reliable machinery. It is ideal for milling, drilling, and tapping operations in medium to large scale industrial productions. S35 features a precision spindle capable of variable speed rotation up to 12,000 rpm, and a tool changing magasine with thirtypositions, enabling working speeds up to 30 m/min. It also features precision linear guides for all three axes, improving accuracy and allowing precise positioning for the various processing operations. KLINGELNBERG S35's operation is implemented by programming its corresponding NC controller. This allows for complex processes consisting of precise sequences, which in turn ensure the highest possible quality and grade of production. In addition, its design allows for easy access, making it easy to reach even complex components and making operations even simpler. This machine tool has an all- cast iron base and a steel fabricated frame which make it factor-2durable and resistant, allowing for long hours of operation with a minimum of downtime. The entire machine frame has been treated against corrosion, and treated with layers of heat and paint to give it a longer life span. S35's machine's working envelope is 500 by 375 by 300 mm and the table surface provides ample space for fixture and clamping of the work pieces and can support most common materials. The strong negative cooling equipment also enables additional operations such as small grinding and surfacing. The innovative control system features a remote operation capability and integrated diagnostic unit. This feature simplifies the usage and offers a full view of the machine's operational data, allowing the operator to monitor and take corrective action if necessary. The control machine also offers multiple CAD/CAM software and machining database integration capabilities. Finally, this machining tool provides easy maintenance and a minimum cost of ownership. Thus, providing its operator with an updated, reliable and productive machine. The Klingelberg KLINGELNBERG S35 is ideal for medium-scale productions, providing engineers with a cost-effective and highly productive machining solution.

There are no reviews yet