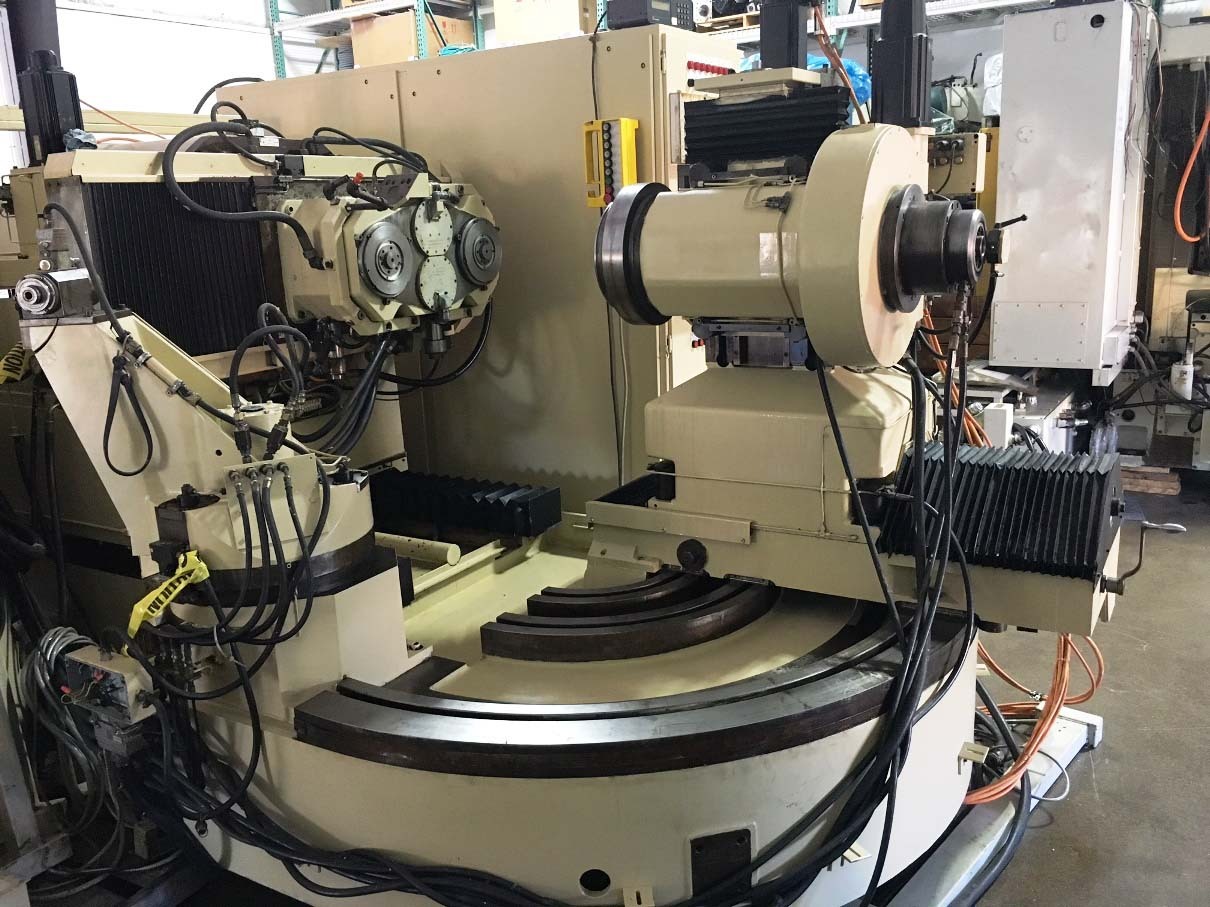

Used KLINGELNBERG WNC 80 #293586818 for sale

URL successfully copied!

Tap to zoom

ID: 293586818

Gear grinder

Size: 800 mm

Work range:

Maximum workpiece diameter: 800 mm

Module range: 1-18 mm

Maximum grindable face width: 130 mm

Swivel range for workpiece spindle head: -5 - 90 Ground

Number of teeth range: 6-360

Axial offset: ±75 mm

Spiral angle: 0° up to standard magnitudes of ~50°

Maximum cone distance: 460 mm

Continuous pressure angle

Grinding wheels:

Unrestricted pressure angle

Grinding wheel diameter: Φ75-473 mm

Grinding spindle revolutions: Up to 5000 min^-1

Workpiece spindle:

Diameter at spindle end: 200 mm

Minimum spindle opening: 155 mm

Maximum mounting distance: 580 mm

Minimum mounting distance: 100 mm

Feeds and speeds:

Maximum generating speed tool head: 23.33°/sec

Maximum generating speed indexing head: 96°/sec

Maximum processing speed infeed: 83 mm/sec

Maximum processing speed transverse slide: 83 mm/sec

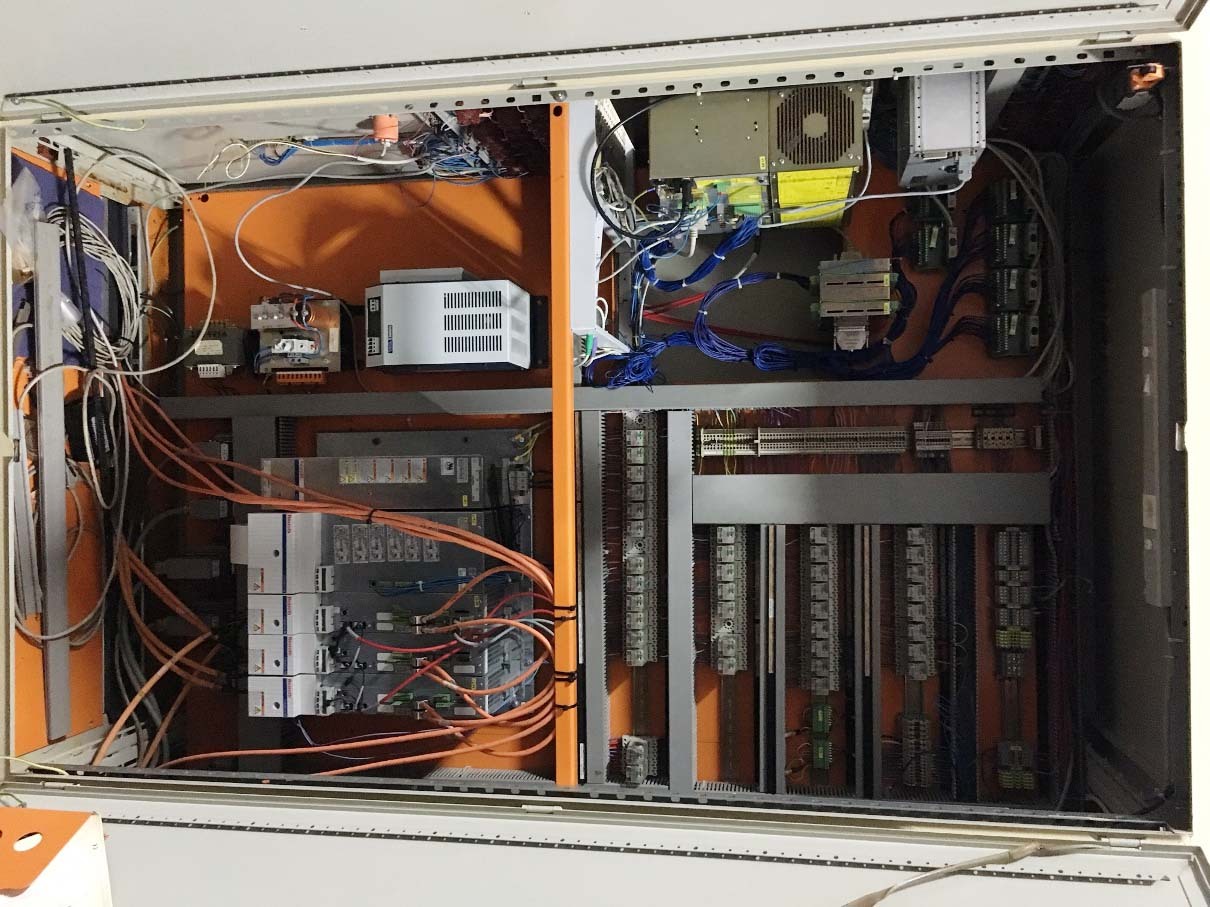

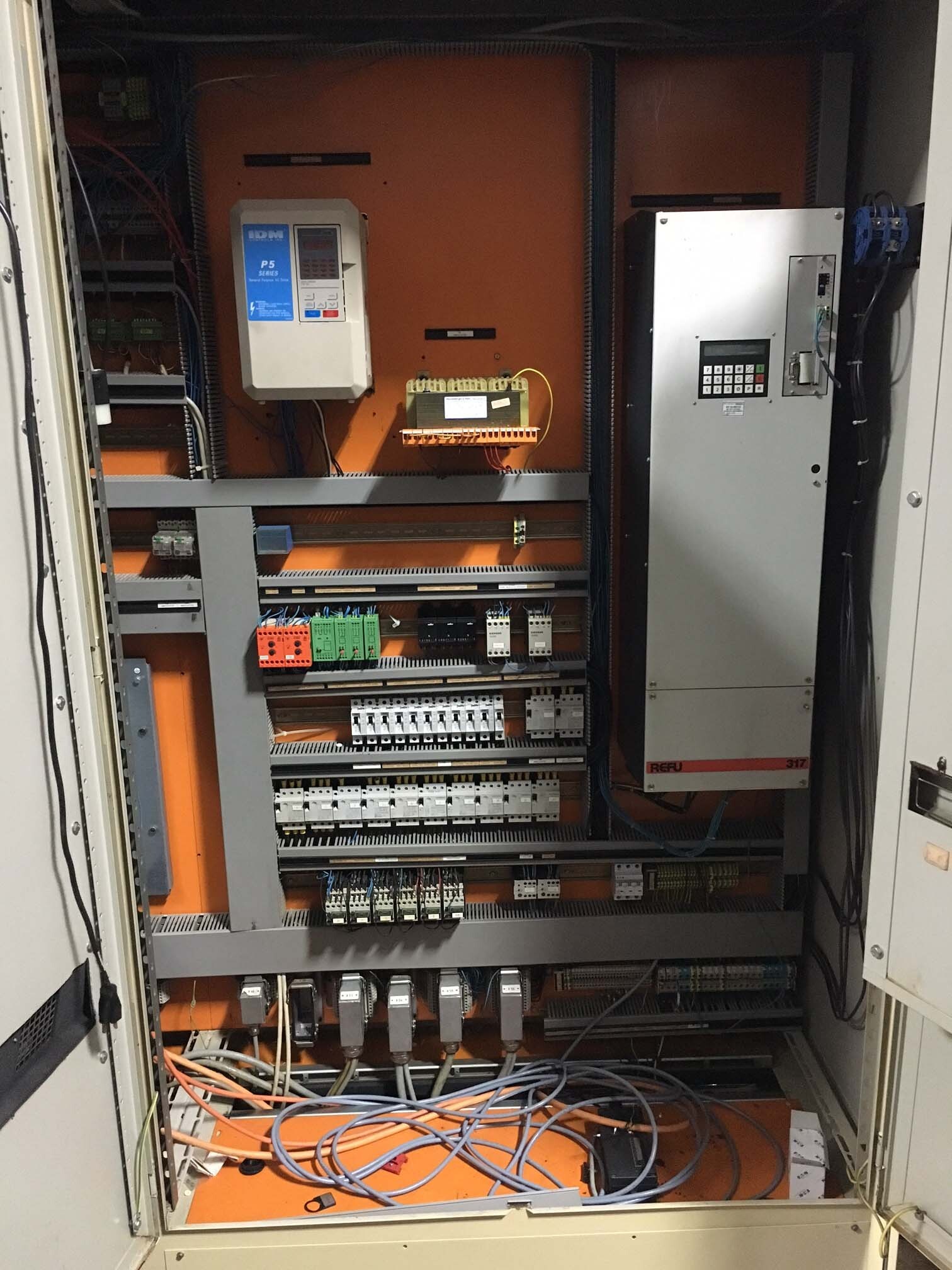

Power and connection data:

24 V Serial interface for serial data input and output

Nominal rating of the motor for the grinding spindle drive: 10kW

Capacity of grinding oil container: 1800 ltr

Capacity of hydraulic oil container: 65 ltr

Capacity of lubricating oil container: 50 ltr

Total connection rating: 19 kW

Power supply: 50/60 Hz.

The Kelingenberg KLINGELNBERG WNC 80 is a machining tool designed for automating complex and difficult machining projects. This machine tool is manufactured by Kelingenberg and is one of the industry-leading precision machining systems on the market for complex machining projects. WNC 80 is driven by high-powered servo motors which offer smooth and efficient handling of the workpiece. The workhead is capable of pivoting from 0° to 90° and is suitable for a variety of machining applications such as drilling, milling, cutting, and tapping. The workhead also features a fixed spindle nose which ensures repeatable accuracies and secure clamping while machining. KLINGELNBERG WNC 80 features a direct drive rotary table and 3-axis CNC control which allows for efficient high speed machining operations. The direct drive table offers heightened accuracy, high-precision positioning, and superior feed rates. The 3-axis CNC control offers efficient and convenient programming and control of the machines' movements, increases production efficiency and enables on the spot corrections and modifications. WNC 80 also features a high-precision linear encoder for superior accuracy along with a superior stator brake for additional security. The machine has a maximum spindle speed of 10,000RPM, and a maximum acceleration of 3G. The worktable is equipped with T-slots and stops to enable customers to quickly and easily fit their workpieces. This machine is also suitable for a variety of materials including stainless steel, aluminum, brass and plastic. KLINGELNBERG WNC 80 is also equipped with safety features such as a safety hood and an emergency stop button to ensure safe and secure operation of the machine's operation. Overall, the Kelingenberg WNC 80 is a powerful, reliable machining tool that is designed to automate complex machining operations with superior accuracy and performance. Its high-power servo motors and direct drive rotary table makes it suitable for high-performance CNC functions, while its safety features ensure secure and safe machining. KLINGELNBERG WNC 80 is an ideal machining solution for automating difficult and high-precision machining projects.

There are no reviews yet