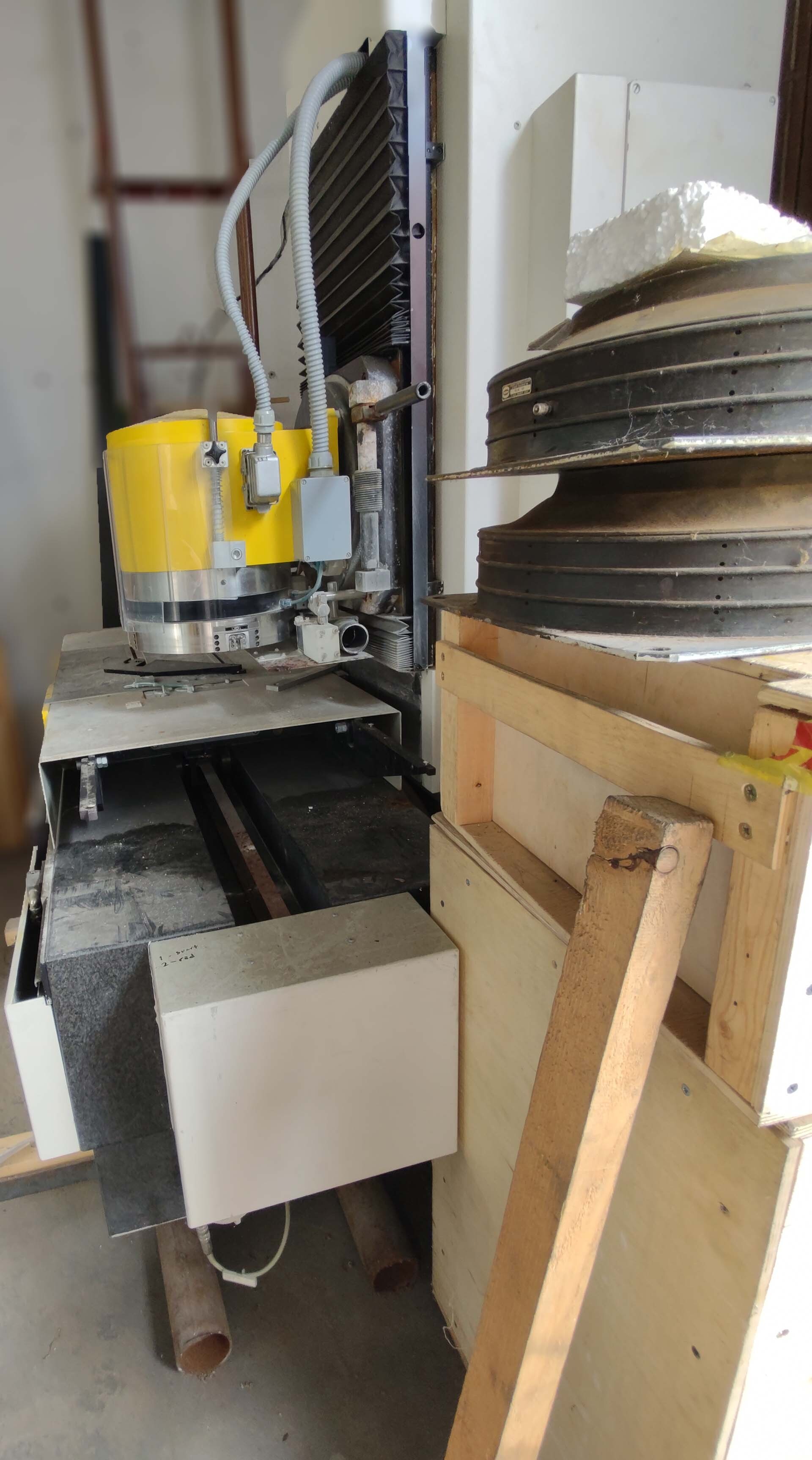

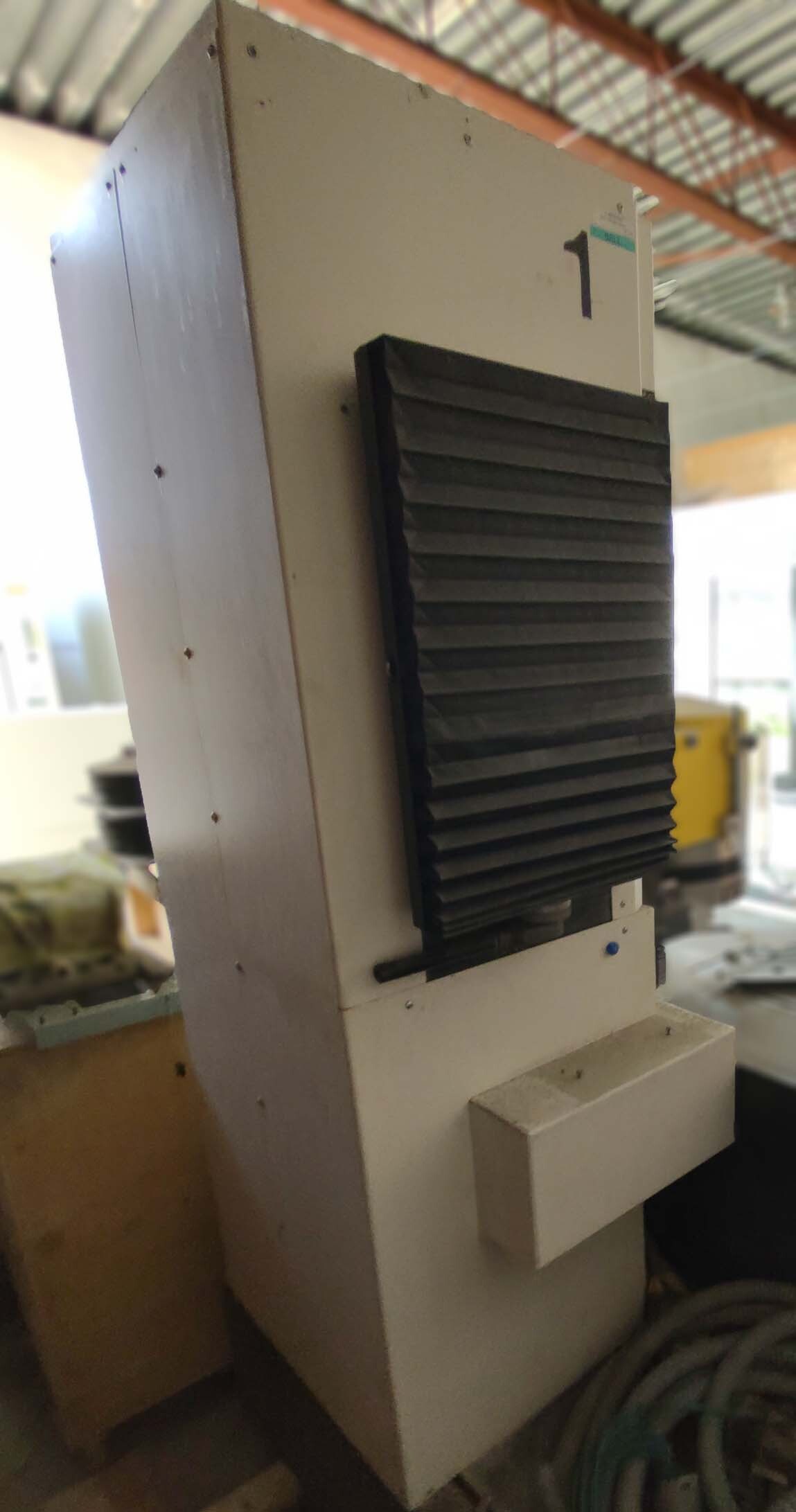

Used KUGLER / OPTIK KUI 2.90 F300/1200 #9383893 for sale

URL successfully copied!

Tap to zoom

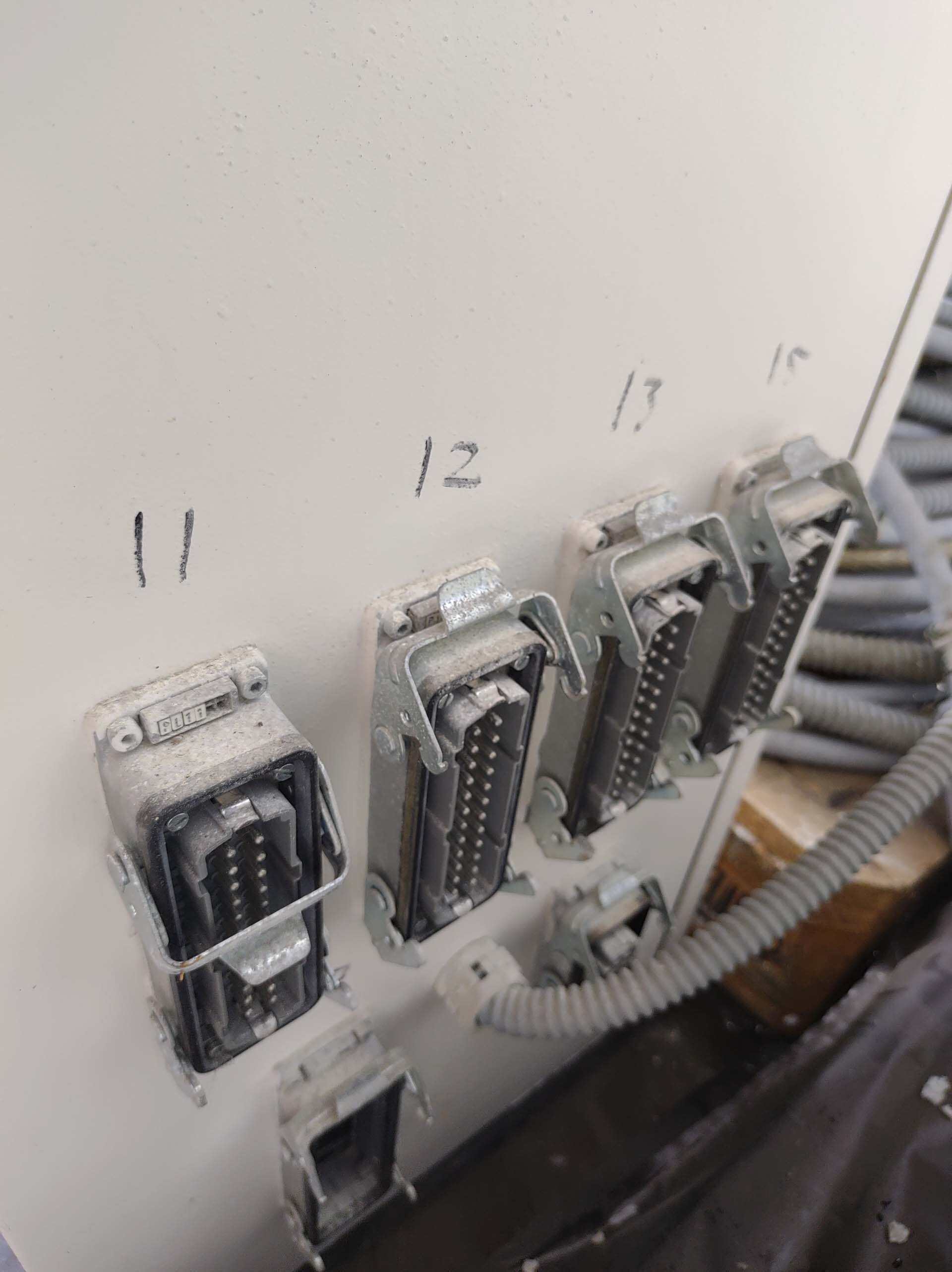

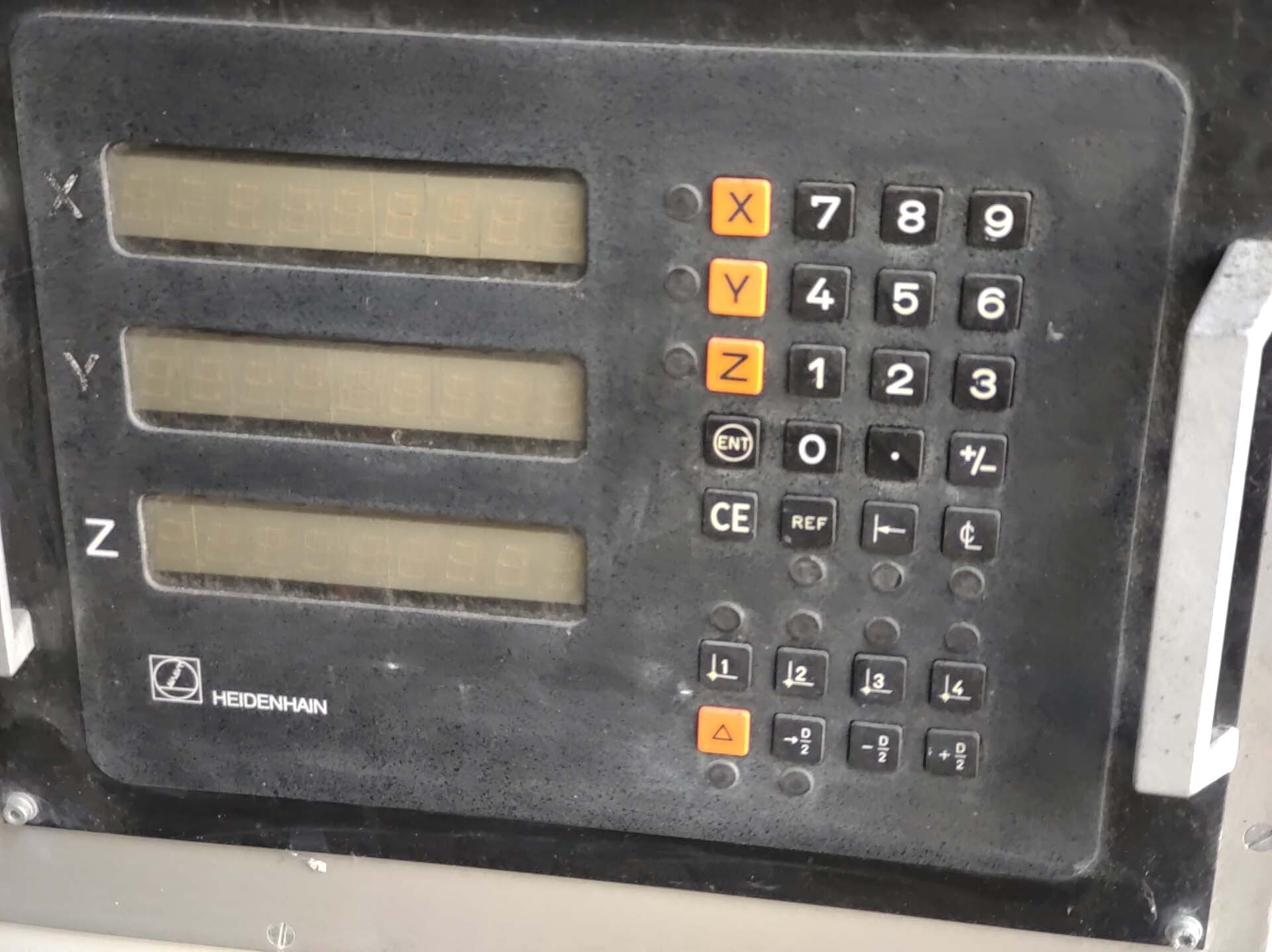

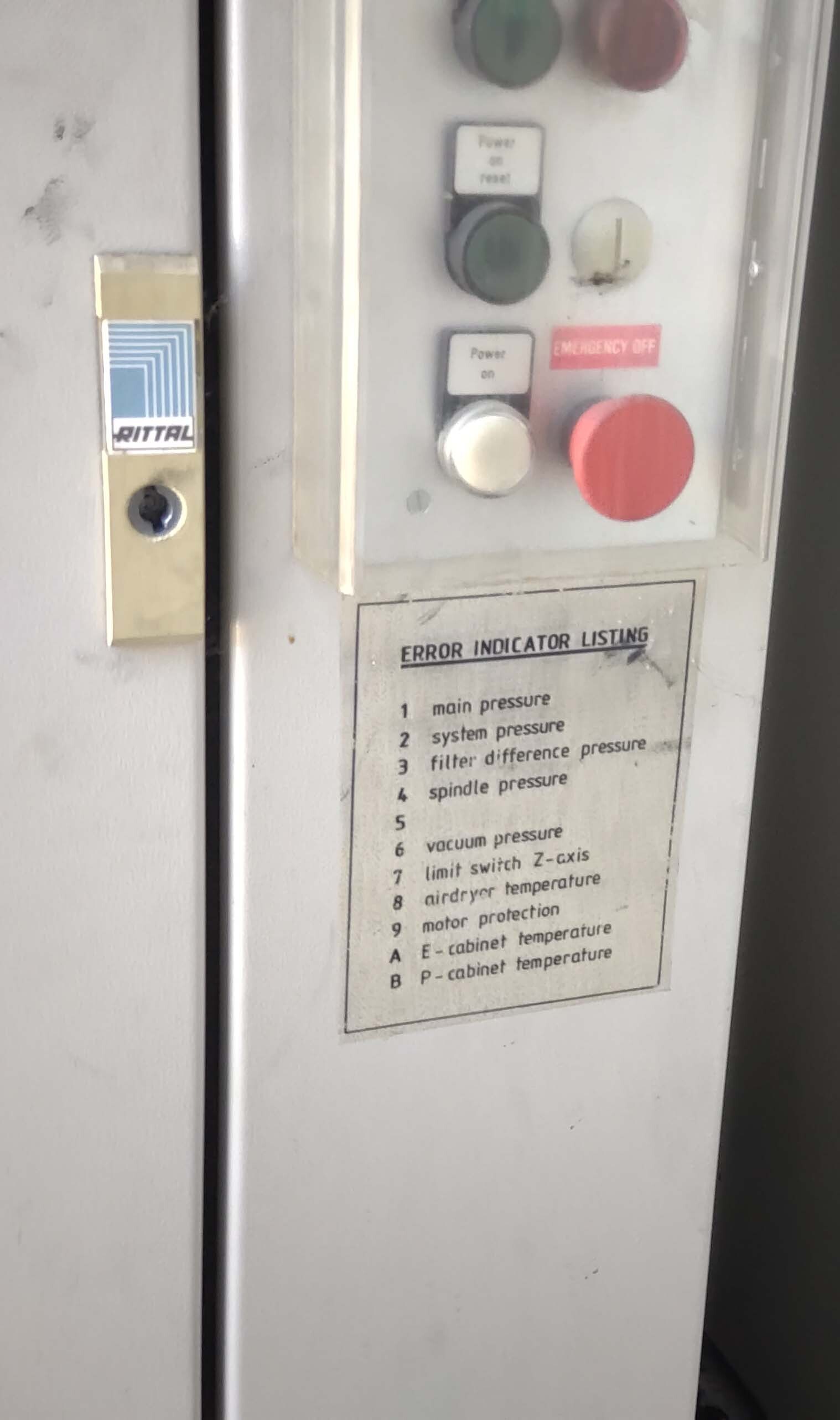

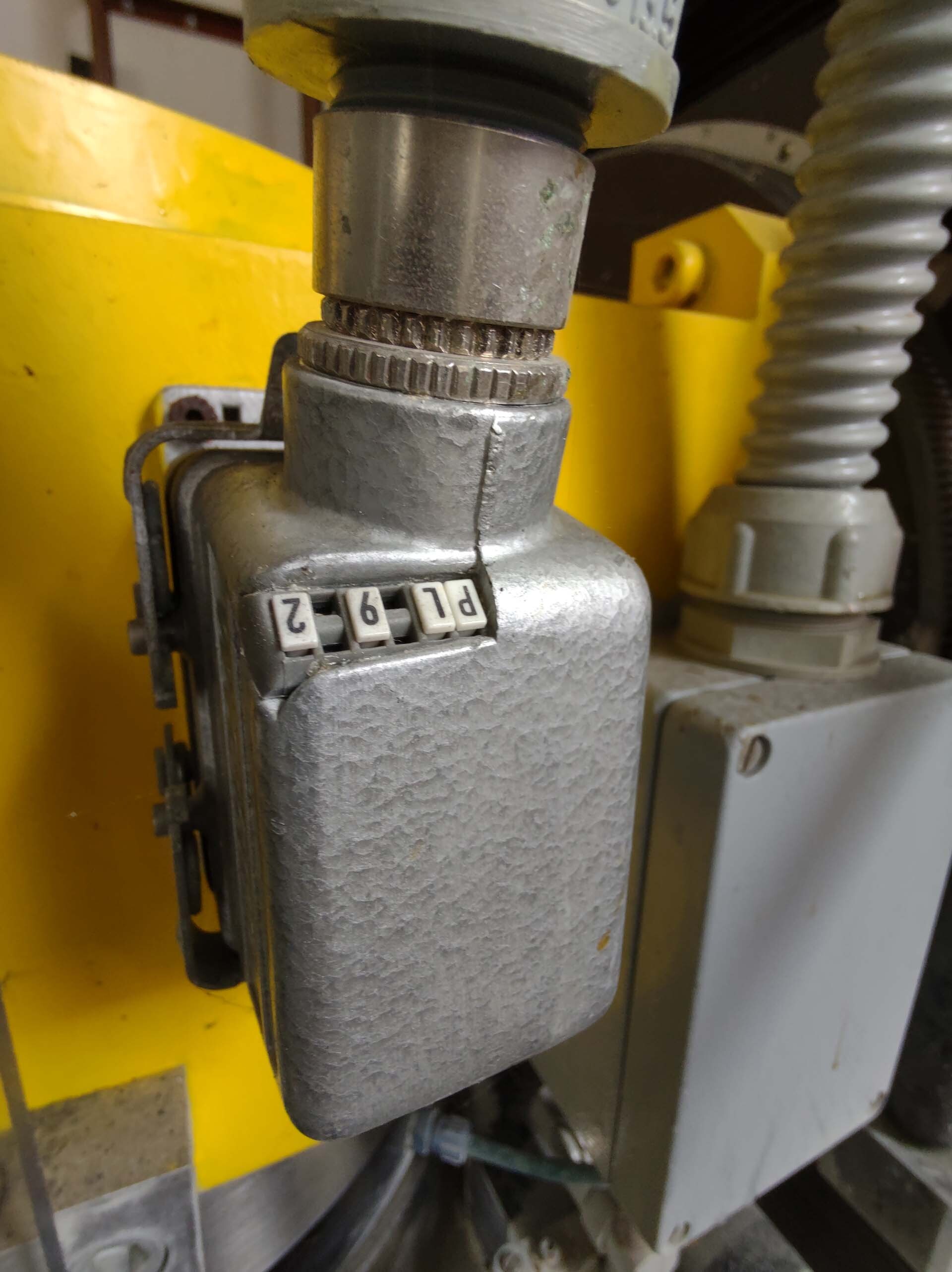

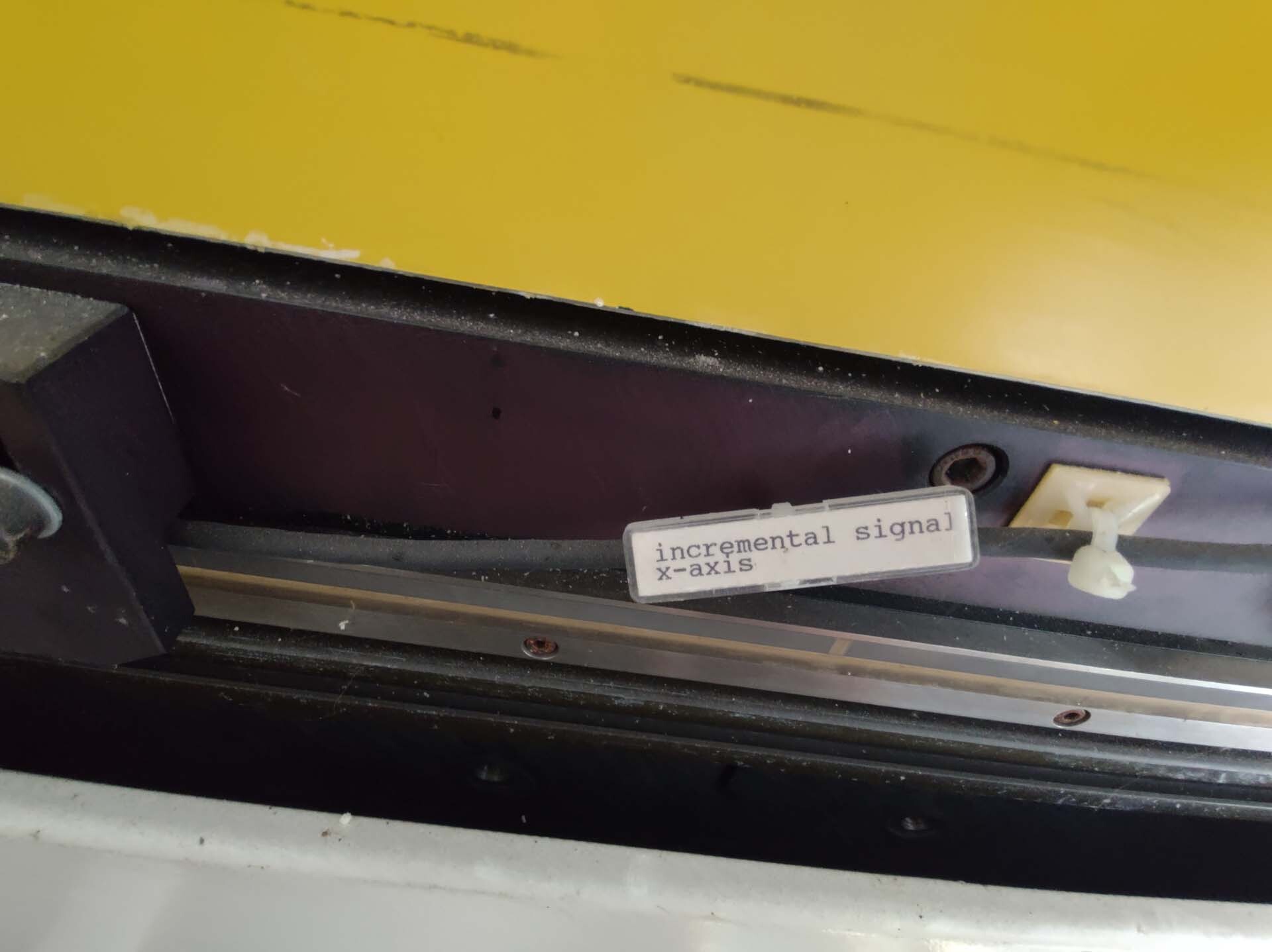

OPTIK KUI 2.90 F300/1200 is a CNC machine tool designed for small to medium sized and complex parts machining on steel, aluminum and other materials. The machine has a 300 mm table travel and vertical movement of up to 1,200 mm for machining of up to 500 mm in diameter. The linear guideways ensure high dynamic performance with a maximum speed of 20 m/min and the rigidity of the frame ensures high machining accuracy. The machine is equipped with a modern 15 kW SINUMERIK 840D CNC controller to integrate the machine functions and provide intuitive operation for easy and reliable processing of varied machining cycles. KUGLER KUI 2.90 F300/1200 is equipped with a spindle head with 12,000 rpm, accompanied by a high-torque motor that can produce a continuous torque of up to 126 Nm. This dynamic spindle is driven by a three-phase current motor with a frequency converter and has a high tool change capacity of up to 30 tools in controlled versions. The spindle motor has a thermal overload protection equipment to prevent the motor from overheating. Furthermore, encoders ensure fine positioning accuracy. The machine features a digital axis positioning system with dedicated position controllers that enable precise and rapid positioning of the axes in order to meet with the machining requirements. KUGLER / OPTIK KUI 2.90 F300/1200 is also equipped with a flood cooling unit controlled by a programmable pressure controller for reliable lubrication of tools and workpiece during operation. Additionally, the machine is designed with a cooling mist suction machine to ensure clean and safe working environment. In addition, the machine is fitted with a manual U and V travel slide and a number of safety features, including a comprehensive safety tool, emergency stop button with a safety monitoring sensor, a hinged safety door, and a penetration guard with electrical isolation and a safety switch for safe access. Moreover, OPTIK KUI 2.90 F300/1200 is equipped with additional accessories such as a DRO, a work piece measuring asset, a spindle pre-positioning control, automatic tool-offset calculation, tool-tip radius compensation correction and an automatic tool breakage detection model. Finally, the machine is designed for a long service life due to its robust structure and reliable components.

There are no reviews yet