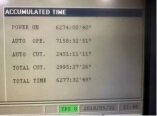

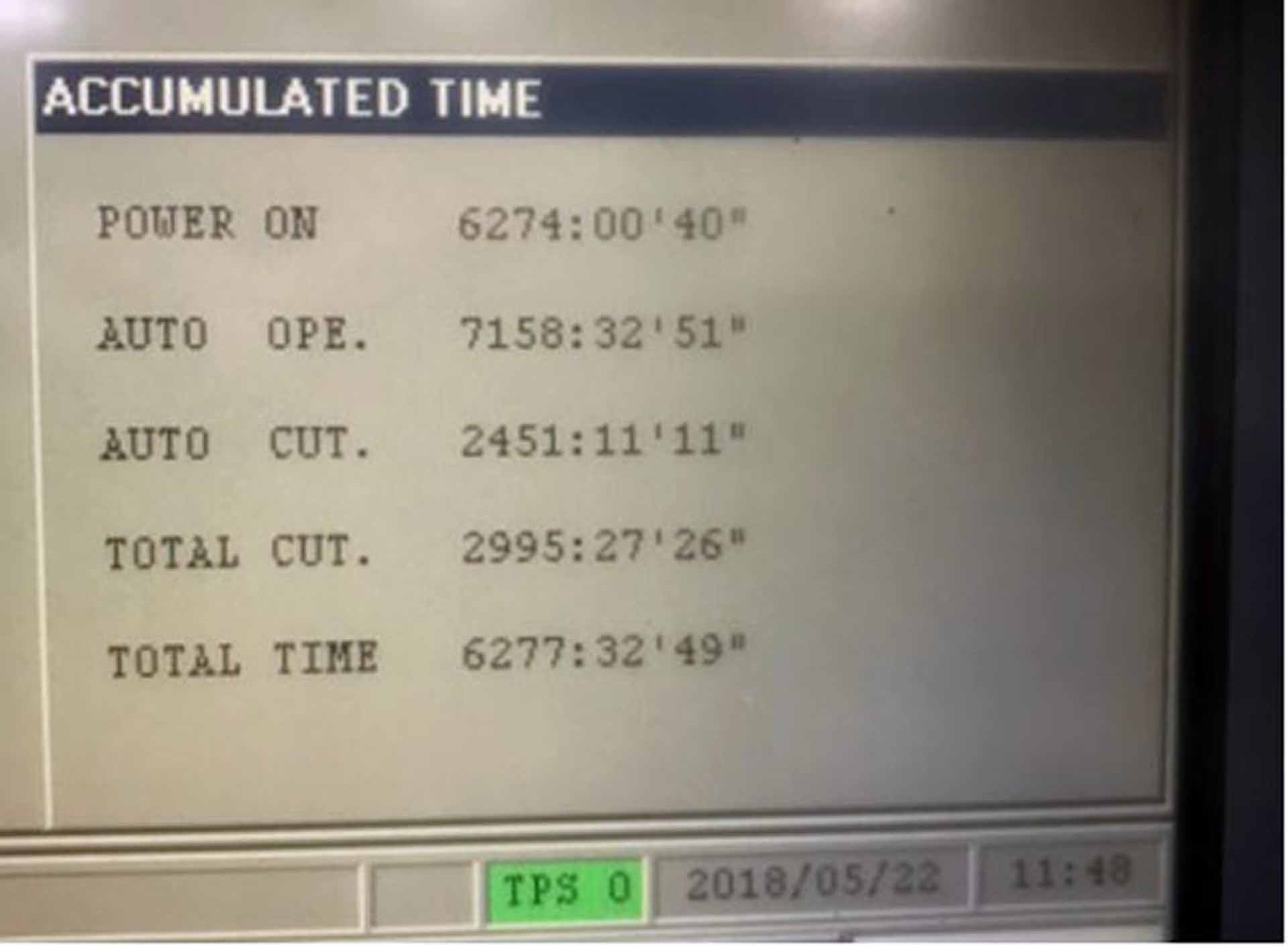

Used MAZAK FH 6000 #9220585 for sale

URL successfully copied!

Tap to zoom

ID: 9220585

Vintage: 2000

Horizontal machining center

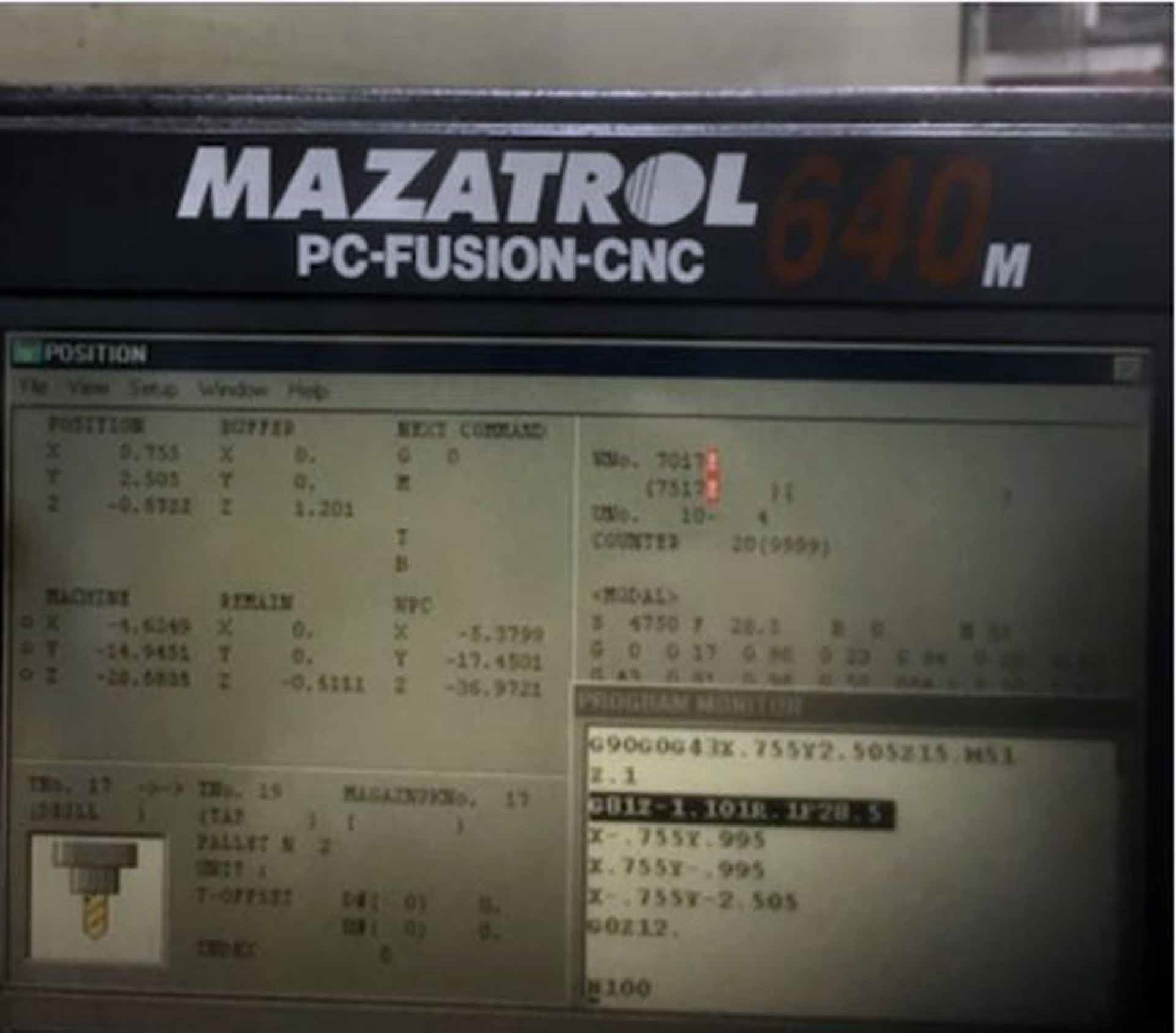

Control: MAZATROL PC-Fusion-CNC 640M

Pallet size: 19.69" x 19.69"

X-Axis travel: 31.5"

Y-Axis travel: 31.5"

Z-Axis travel: 34.7"

Pallet index: .001 positioning

Distance of spindle center to top of pallet: 3.9" - 35.4"

Maximum table load: 2,200 lbs

Max workpiece height: 40"

Max workpiece diameter: 36"

Spindle taper (Cat / Bt)

Cat: #50

Spindle motor: 40/30 HP

Spindle speed: 7,000 RPM

Spindle speed increment: 1 RPM

Tool changer type: 80 ATC

Obtains full hp: 480 RPM

Constant torque range: 35 - 480 RPM

Range

Options / Equipped with:

Dual rear discharge chip conveyors

(2) pallets changer with T slots

MAZATROL & EIA / ISO Programming language

10.4" color LCD (Liquid crystal display)

Dual rear discharge chip conveyors: (2) Screws feeding into belt

Prep for mmsb optical MP10

IC Memory card interface (Download / Save only RS-232)

3.5" Floppy disc drive

Tool life monitoring (MAZATROL)

Tool breakage recovery (MAZATROL)

Tool length measurement (MAZATROL)

Synchronized tapping background

Tool path check (MAZATROL)

Coolant thru spindle

2000 vintage.

MAZAK FH 6000 is a high efficient machine tool that produces accurate parts at high speeds and is designed to meet customer requirements for a variety of machining operations. The machine's main features include a 10,000 RPM spindle, a lock-type spindle nose, and a large 180-degree rotary table. With its help of an optional 3-dimensional monitoring equipment, FH 6000 is capable of performing efficient and accurate finishing operations on large parts. The spindle of MAZAK FH 6000 is powered by a 24HP spindle motor with a maximum speed of 10,000RPM. This permits rapid machining and allows the machine to work with small to large parts, making it ideal for industries that need high precision parts. The spindle is supported by a high-speed roller type bearing that provides maximum rigidity and accuracy. Additionally, the machine is designed with rigid construction for reduced vibration, faster acceleration, and smoother operation. The lock-type spindle nose is another feature of FH 6000 that prevents the collet from slipping while machining. This unique feature also contributes to increased accuracy and precision. The table has a switching time of 1.5 sec that is suitable for efficient machining. It is supported by four separate servo motors and is equip with a high speed direct drive system that delivers smoother rotation and higher rigidity when compared to other machines. The optional 3-dimensional monitoring unit of MAZAK FH 6000 machine is capable of controlling the workpiece's position and size. It can also detect vibrations, deformation, and displacement to ensure highly accurate finishing operations. This is beneficial for users who require accurate, separate parts or those who need to make parts with complex geometries. FH 6000 is designed for efficient and precise cutting processes, making it a favorable machine for those in the heavy machining industry. With its robust design and features, such as a high-speed spindle, lock-type spindle nose, and 3-dimensional monitoring machine, users can trust the device to produce quality and accurate machining parts. Additionally, the machine is designed with efficient acceleration, reduced vibration, and smoother operation that increases production output while reducing costs.

There are no reviews yet