Used MAZAK Integrex 200-3T #9043659 for sale

URL successfully copied!

Tap to zoom

ID: 9043659

Vintage: 2004

CNC turning center, 8"

Mazatrol Fusion 640MT controller

Maximum Swing 26"

Maximum Cutting Dia. Chucking Upper 26"

Max Cutting Length 40"

Max Distance between Chuck Jaws 45.27"

Max Swing over lower Turret 10.6"

Max Cutting Dis Chucking Lower 10.24"

X Axis Travel 22.83"

Y Axis Travel +/- 3.15"

Z Axis Travel 41.14"

X2 Axis Lower Travel 5.91"

Z2 Axis Lower Travel 38.98"

B Axis Travel 225 Degrees

C Axis Increment 0.0001 Degree

Main Spindle Nose / Bore A2-6" / 2.99"

Spindle Speed 35 - 5000 RPM

Spindle Motor 30 min. / continuous 30 HP / 25 HP

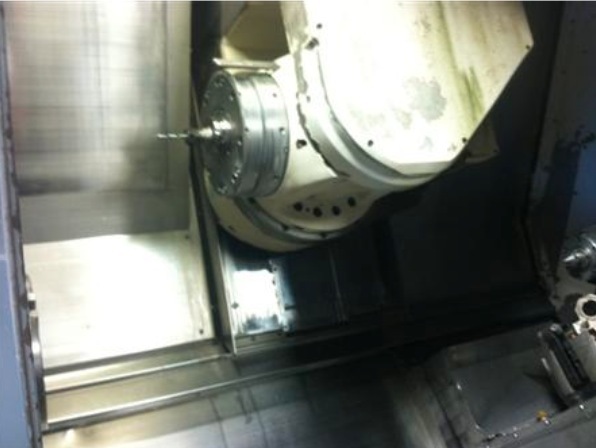

Rotary Tool Spindle Speed 12,000 RPM

Rotary Tool Spindle HP 25 HP

Magazine Capacity 40 Positiion ATC KM63

Lower Turret 9 Position Drum

8" Hydraulic Chuck

Automatic Tool Eye

C Axis Spindle Rotation

Y Axis Capability

B Axis Single Position Pendulum Style Turret

9 Station Lower Turret

Chip Conveyor Side Discharge

40 Position Tool Changer w/ KM 63 Nose

213 High Pressure Coolant Thru the Spindle

Programmable Tailstock

Complete Coolant System

Chuck Air Blast

PCMCIA Interfac - 2 Slots

3.5" Floppy Disk Drive

RS 232 Port Interface

All Available Manuals

All Available Tooling

Cut Mostly Aluminum

2004 vintage.

MAZAK Integrex 200-3T is a powerful and precise, multi-tasking, turning and milling machine tool, produced by MAZAK, a leading Japanese manufacturer of machine tools and related products. Integrex 200-3T has a 12-station, B-type turret and is outfitted with an 8/5-inch straight-select Live Tooling that is replaced with rapid ATC outfitted with a 12-position "Groove Tool Cage" rotary turret for internal and external turning operations. It can process a wide range of materials in a quick and efficient manner. The machine's main chuck is 8"/5" and is fitted with a tooling package of three-jaw E-type chucks, driven by a servomotor. It provides improved instant repeatability and durability, designed to increase the machine's overall productivity. The C-axis selector adds even more versatility to MAZAK Integrex 200-3T with its ability to quickly select the number of revolutions and rotations for each tool. It offers four-axis contouring control and a full range of simultaneous spindle indexing and interpolation functions. The machine's Y-axis provides improved performance for machining operations and is also equipped with a high-speed tool changer, which enables tool switching even while the spindle is in motion. The spindle itself employs a liquid-cooled, high-torque motor making it suitable for heavy-duty cutting. The spindle has a maximum speed of 3,000 RPM and a maximum thrust of 2,000 lb-ft. In addition, the spindle has a full range of servo motors for providing unequalled accuracy and responsiveness. The machine comes with a standard suite of operator controls, including axis selectors, speed reversals, and feed selectors, which deliver complete control over the machine operations. The machine is powered by a Mazatrol Fusion 640MT CNC system, which offers superior control over the machine operations. It has a large colour LCD monitor that allows viewing of all relevant processes and provides automated real-time data collection. Other features of the machine include a built-in chip conveyor, chip buckets, coolant supply, automatic tool length sensing, automatic tool presetting, and auto-tool breakage detection. Integrex 200-3T sets a new benchmark for a combination of power and precision, and is capable of producing highly accurate machined parts in a short amount of time.

There are no reviews yet