Used MAZAK Integrex 200 II SY #9221116 for sale

URL successfully copied!

Tap to zoom

ID: 9221116

Vintage: 2002

Multi-axis CNC turning center

Specifications:

Maximum swing / Swing over carriage: 26"

Maximum turning diameter: 26.5"

Length: 40"

Spindle distance: 41.14"

Main spindle: 50-5000 RPM

Spindle bore: 2.99"

Spindle bar cap: 2.5"

Spindle nose: A2-6

Sub-spindle nose: 50-5000 RPM

Spindle motor: 25 HP

Turret number of positions: 40 Tool ATC

Travels:

X-Axis travel: 22.83"

Z-Axis travel: 41"

Y-Axis travel / Tilt head: 3.15" +/- / 225°

Sub-spindle stroke: 40"

Indexing main & sub spindle: 360,000°

Rotary tool speed: 12000 RPM

Rotary tool motor: 20 HP

Rapid traverse (X & Z): 1496

Rapid traverse (Y / Sub spindle): 1024 / 1181 IPM

Equipped with:

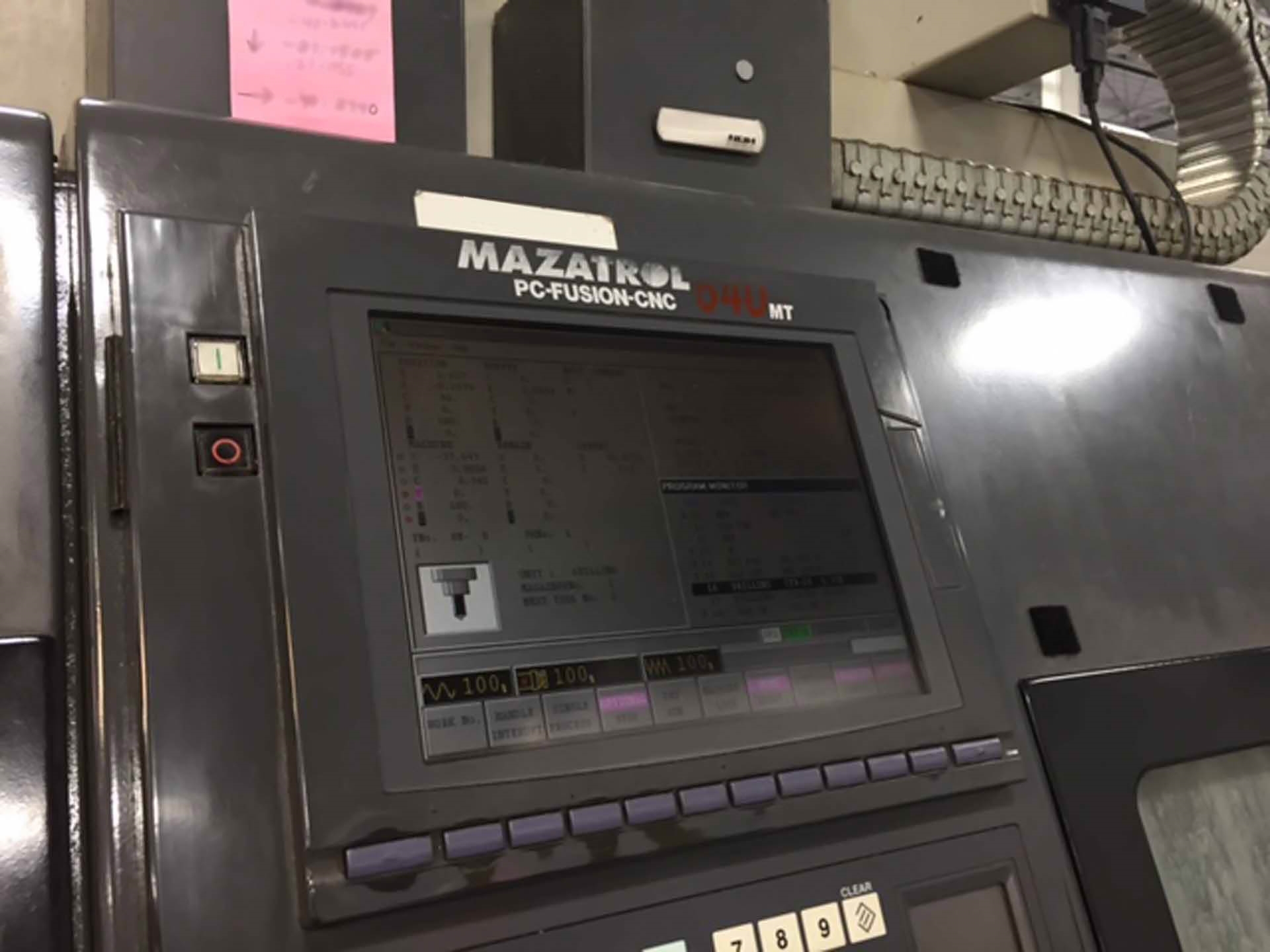

MAZATROL FUSION 640 T

Chuck on main spindle, 8”

Chuck on sub, 8"

Automatic tool eye

Tool life monitor

Chip conveyor

Live tooling capable

Conversational programming

Graphic display

Milling spindle synchronous tapping

EIA / ISO Input function

Background path check

Parts catcher

Coolant through milling head

2002 vintage.

MAZAK Integrex 200 II SY is a multi-tasking machine tool designed for high precision and efficiency in today's machining operations. The machine has a 330mm spindle, which allows it to accommodate work pieces up to 420mm in diameter with a maximum length of 550mm. The spindle features a maximum speed of 6,000rpm and allows for multi-tasking capabilities for turning and milling operations. Integrex 200 II SY offers a variety of features, which allow it to be used for a host of production operations. The equipment provides a fully programmable 12-axis CNC, with up to 34-tool changer and tool storage capacity. This provides the capability for performing multiple machining operations; including milling, drilling, tapering, threading, knurling, profiling, grooving, sawing, broaching, chamfering, and much more. It also features an equipped coolant system with an oil/water separator for efficient cooling of cutting tools during operation. MAZAK Integrex 200 II SY also utilizes multiple linear axes, providing up to 6 axes of interpolation along with digital servo motors and feedback control. This provides for a high degree of accuracy for the machining processes, thus providing ensures quality production each time. The unit also features a spindle headstock tilt for multi-axis machining, two independent pallets for quick and easy workpiece setup and transfer between machining areas, an automatic piece measuring machine, and a resident linear scales. To ensure reliability and ease of use, Integrex 200 II SY features an operating tool that is based on native Windows software. This allows for ease of operation and assists in simplifying the programming of the numerous operations with a comprehensive user-friendly interface. The asset also has a user friendly colour LCD monitor, for clear view of the process display and machine conditions. Overall, MAZAK Integrex 200 II SY is a powerful and reliable machine tool that is capable of tackling a wide range of production operations. It is highly reliable, efficient, and user friendly, allowing the user to maximize quality and minimize machining time. With all of these features, Integrex 200 II SY is a great choice for production operations that require high accuracy and precision in machining operations with a short lead time.

There are no reviews yet