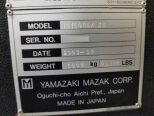

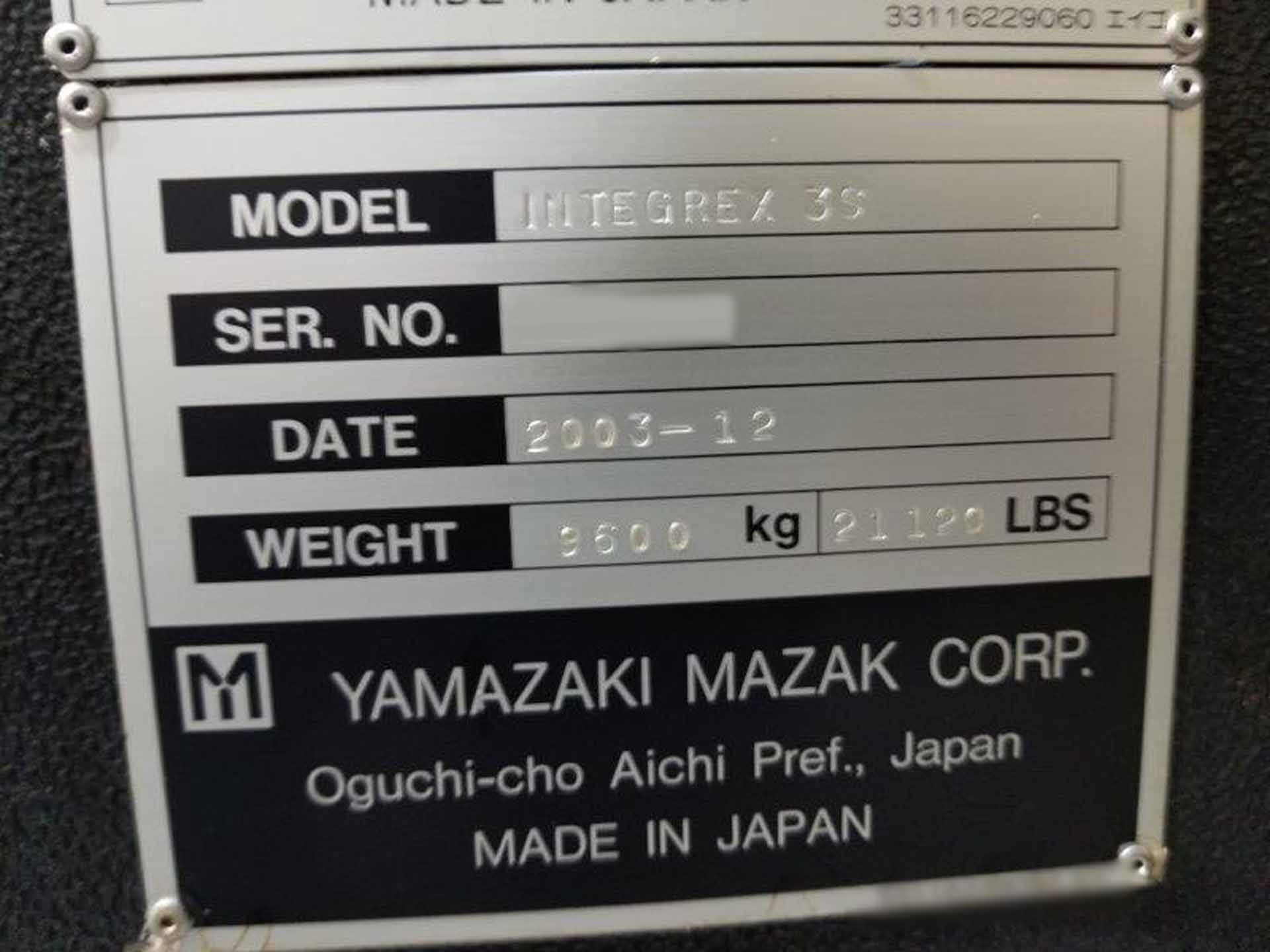

Used MAZAK Integrex 200-IIIS #9210886 for sale

URL successfully copied!

Tap to zoom

ID: 9210886

Vintage: 2003

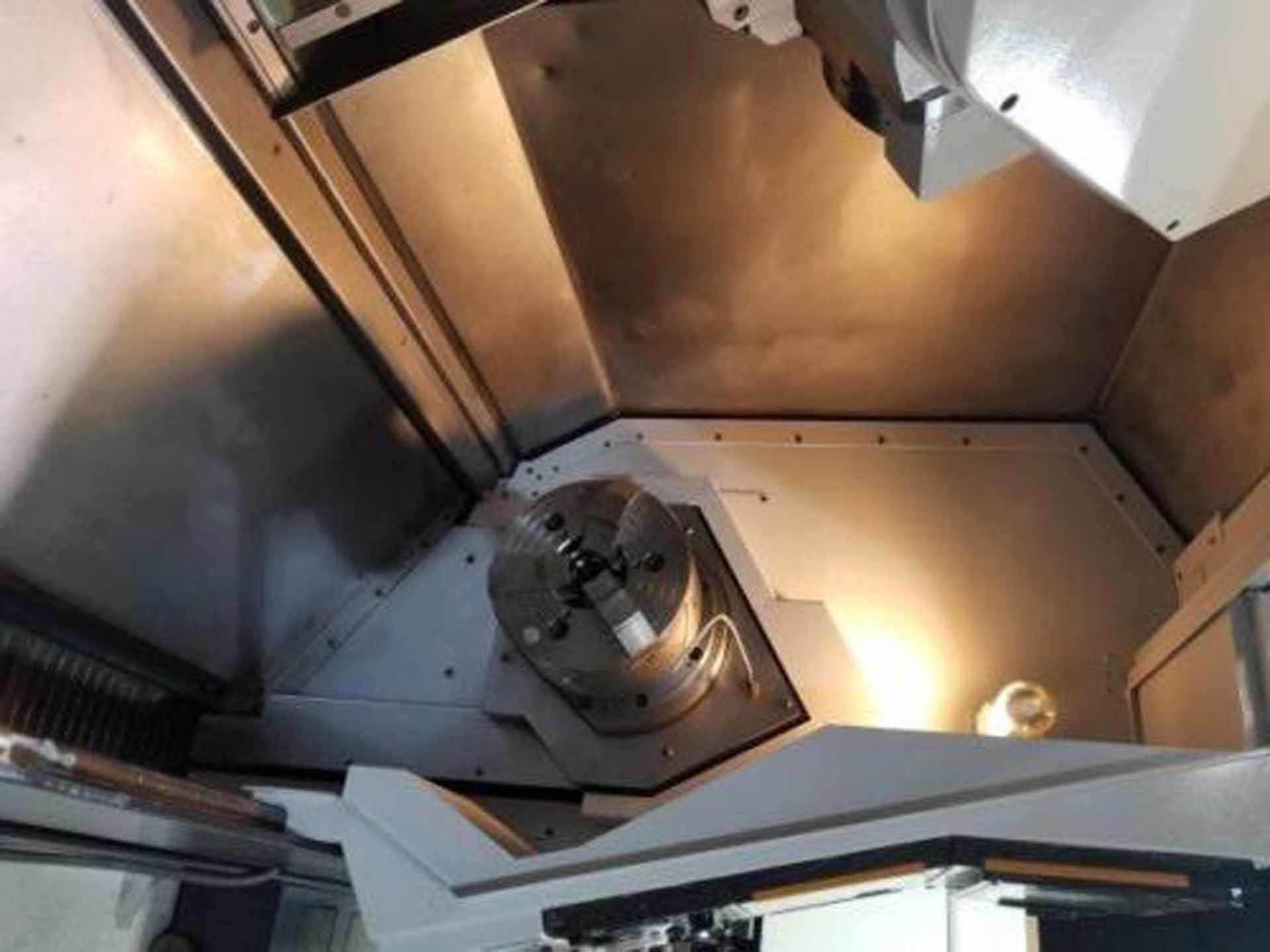

Multi-Axis CNC turning center

With sub-spindle & C-Axis

Specifications:

Maximum swing: 26"

Maximum turning length: 60"

Main spindle nose: A2-6

Spindle speeds: 5000 RPM

Spindle bore: 3"

Spindle motor: 30 HP

Sub-spindle nose: A2-6

Spindle motor: 25 HP

C-Axis rotation: 0.0001 Index

Tool changer capacity: (40) Stations

Z-Axis travel: 41.14"

X-Axis travel: 22.83"

Rotary tool speed: 12000 RPM

Equipped with:

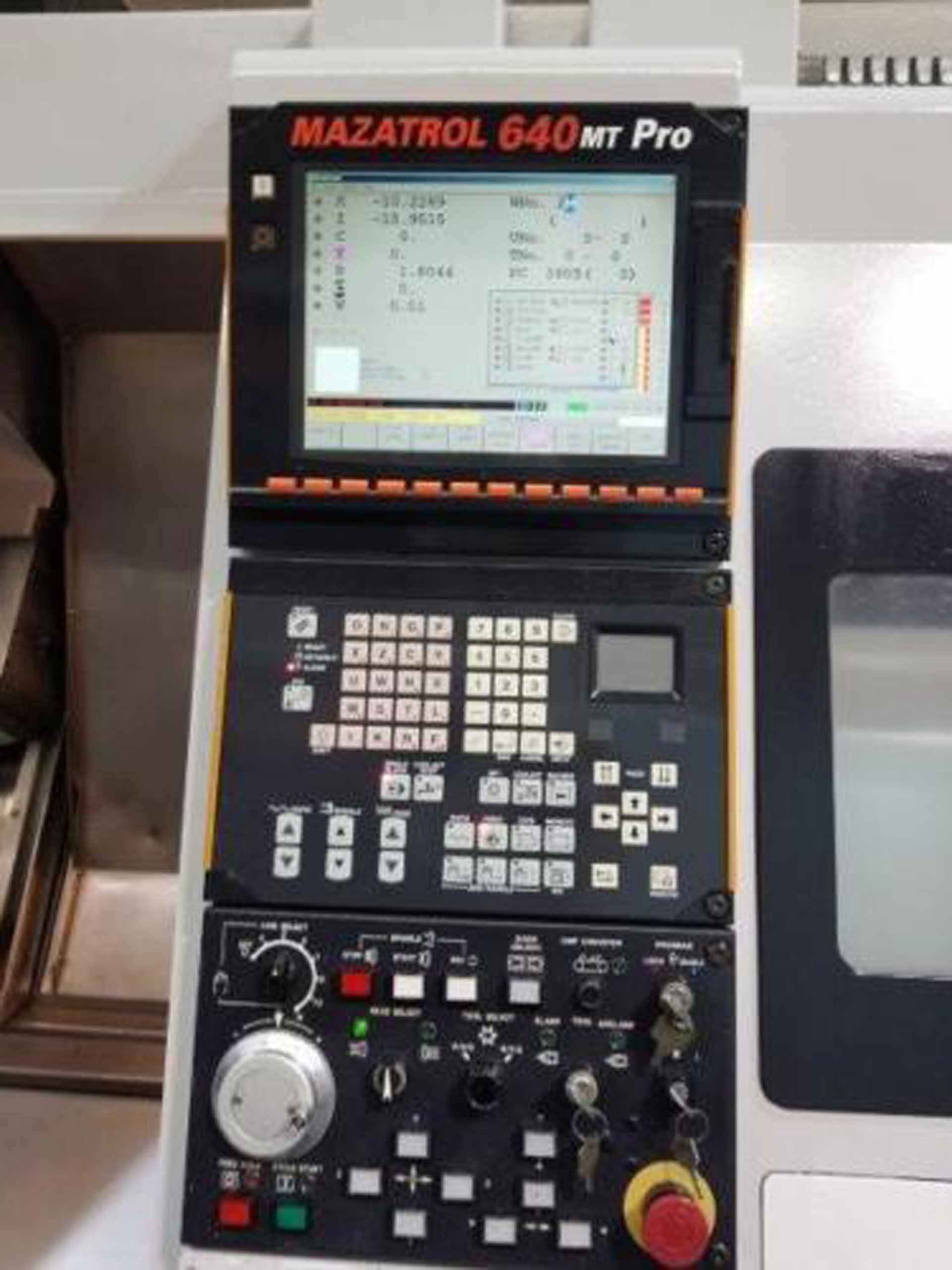

Mazatrol 640 MT-Pro CNC control

Coolant through milling head

2nd C-Axis spindle 0.0001 degree increment

15000/213 Psi thru Coolant/Flood coolant simultaneous-flowable

High/Low chuck press system: First & second spindle

Double foot switch: First & second spindle

Coolant temperature control system

Cylindrical interpolation command G07

2003 vintage.

MAZAK Integrex 200-IIIS is an advanced multiaxis machine tool designed to perform a wide range of machining operations with superior precision. It has a rigid and stable base construction and a highly dynamic, direct drive spindle. This makes it possible to achieve high accuracy and surface finishes while providing a wide range of cutting speeds. The integrated spindle motor also provides an added degree of rigidity and stability to the machine tool. Integrex 200-IIIS has advanced tooling capabilities that make it possible to produce parts that require complex turning and milling operations. The multitasking function is combined with multiple axis capabilities that enable machining on multiple axes in a single machining cycle. This machine is able to perform simultaneous machining and turning operations on multiple materials. The machine features a 60-tool magazine, a 10-position turret, and a 42-position tool changer for an extensive selection of tooling. The advanced control system makes it possible to program complex machining operations and perform all machining operations automatically. The associated advanced software also enables the users to display 3D models and visualize machined parts while operation. The control system is a Fanuc 30i with 15" touchscreen color LCD and 12,000 block capacity, providing added flexibility and control. MAZAK Integrex 200-IIIS has a working area of 16.5" x 20" x 21.6." It has an automatic measurement tool that can be used to measure and correct machine positioning for greater accuracy. The machine can handle material up to 5,300 lbs. It has an integrated coolant system that helps maximize efficiency by avoiding material buildup and keeping tooling clean. The highly reliable design of Integrex 200-IIIS can be seen in the ability to provide high productivity and long-term repeatability with minimum maintenance and setup times. Additionally, the machine tool is also equipped with a wide array of safety features such as barriers and covers, electrical and mechanical interlocks, and encoders as standard components. All in all, MAZAK Integrex 200-IIIS is a powerful and reliable machine capable of a wide range of machining tasks and operations. Its superior accuracy and quality output make it an ideal choice for any complex machining operation.

There are no reviews yet