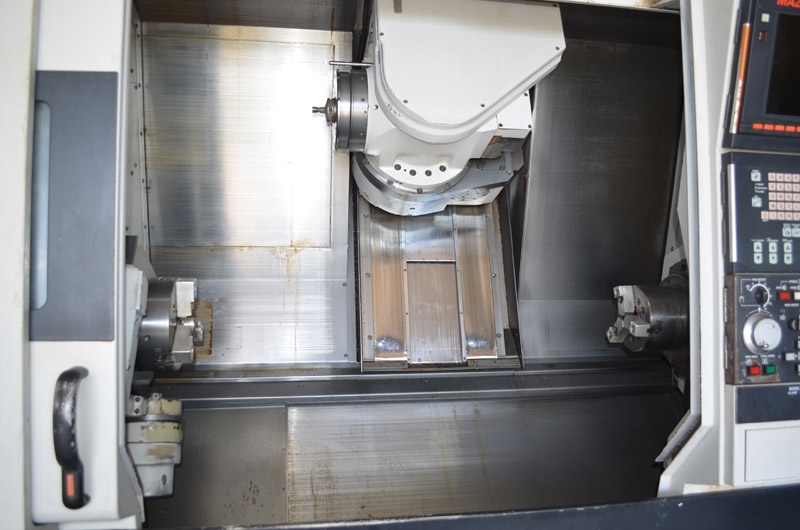

Used MAZAK Integrex 200-IIIS #9296620 for sale

URL successfully copied!

Tap to zoom

ID: 9296620

Vintage: 2004

Multi-Axis CNC turning center

With sub-spindle & Y-Axis

Specifications:

Maximum swing: 26"

Maximum swing over carriage: 19.7"-26"

Maximum cutting diameter: Chucking, 26"

Maximum cutting length: 40"

Maximum distance between standard chuck faces: 41.14"

Main spindle specifications (L):

Spindle nose: A2-6

Spindle bore: 2.99"

Maximum bar work: 2"

Spindle speed / Ranges: 35 - 5,000 RPM / 2

Spindle index (Programmable): 0.0001°

Spindle horsepower (Cont./30 Mins.): 20/30 H.P. (A.C.)

Spindle torque: 258.1 ft-lbs

Second spindle specifications (R):

Spindle nose: A2-6

Spindle bore: 2.99"

Maximum bar work: 2"

Spindle speed / Ranges: 35 - 5,000 RPM / 2

Spindle index (Programmable): 0.0001° C-Axis

Spindle horsepower (Cont./30 min): 20/25 HP (A.C.)

Spindle torque: 241 ft-lbs

Turret and tooling specifications:

Type of turret: 1 Position, with ATC

Tool shank height: 1.0"

Tool size (Boring bar max. dia.): 1.5"

Magazine capacity: 40 Tools

Tool selection method: Random

Tool to tool ATC Time: 1.3 Sec.

Max. tool diameter with all pockets full: 3.54"

Max. tool diameter with adjacent pockets empty. 4.92"

Max. tool length (From gauge-line): 11.8"

ATC Tool shank: KM

Rotary tool spindle speed / Ranges: 12,000 RPM / 1

Rotary tool spindle horsepower (20% ED). 25 H.P. (A.C.)

Rotary tool torque (20% ED): 88.2 ft-lbs

Maximum face mill: 4"

Maximum end mill: 1.25"

Maximum drill: 1.18"

Maximum tap: 1-8 UNC

Axis travels:

B-Axis: 225° (0.001° Increments)

Y-Axis: +/- 3.15"

X-Axis: 22.83"

Z-Axis: 41.1"

Second headstock W-Axis: 41.34"

Axis rapid rates:

Y-Axis: 1023 IPM

X-Axis: 1496 IPM

Z-Axis: 1496 IPM

Second headstock W-Axis: 1181 IPM

C-Axis: 400 RPM

General specifications:

Floor space (W x L x H): 87.1" x 150.39" x 102.24"

Machine weight: 21340 lbs

Equipped with:

MAZATROL Fusion 640MT PRO Control

PCMCIA I/F (2-Slots, card bus)

Network interface (For LAN and MODEM)

Y-Axis control

Coolant through milling head

Flood coolant: 213 PSI Through

C-Axis: 0.0001° (1st Spindle)

2nd Spindle C-axis: 0.001°

Tool magazine: 40 KM

B-Axis: 0.0001° Increment N/A contouring

B-Axis: Index 5° (Coupling clamp)

Chip conveyor side disposal (Consep)

Automatic tool eye

Auto chuck jaws open / Close (1 and 2 Spindle)

Chuck open / Close confirm (1 and 2 Spindle)

Auto power ON / OFF + Warm up

Coolant temperature control

Shower coolant: 38 PSI / 16 Gal

Through hole chuck B-208A615 (1st Spindle) through hole cyl S1552, 8"

Chuck B-208 2nd spindle with non-through hole cyl. Y-1225, 8"

2004 vintage.

MAZAK Integrex 200-IIIS is a multi-tasking, multi-axis machine that provides various CNC Turning, Milling and Drilling capabilities in a single setup. It utilizes a powerful control equipment that offers ample levels of automation, making it ideal for medium-sized and large-scale machining jobs. Integrex 200-IIIS employs a compact bed with a large main spindle and sub-spindle. It offers 3 spindles with a total of 20 tool stations that are enabled with a big-bore bar feeder and gang-style tool changer. It allows for simultaneous milling and turning operations, giving users the ability to produce complex components quickly and with increased accuracy. The machine is driven by a reliable MAZATROL 640MT Pro CNC Control system that runs the latest Version 12 software. The control unit consists of an 8.4" Monochrome LCD screen and a bilingual keyboard for easy manual data entry. It contains memory formats for quick job setup and a library of preprogrammed machining cycles for efficient machining. The machine can be programmed using conversational programming, EIA/ISO, and MAZAK proprietary DNC Parallel Linker software. MAZAK Integrex 200-IIIS also features a powerful AC servo drive motor that offers smooth, stable cutting with high positioning accuracy. It is also equipped with Fanuc's Absolute Position Detection machine for improved accuracy and greater reliability. The integral axis drive technology helps to reduce vibration and deliver consistent, accurate cutting. In addition to its performance, Integrex 200-IIIS is designed with user safety in mind. It is equipped with a rigid boxway (slant-bed) cutting area and electronically interlocked safety doors that prevent access to the cutting area when machining. It also has an operator-friendly manual mode that allows trained personnel to access the machine without fear of disruption. MAZAK Integrex 200-IIIS is an efficient and precise machine tool designed for versatility and reliability. Its wide range of cutting functions and reliable operation make it suitable for a variety of machining operations, including oil, gas, automotive, and aerospace applications. The machine's automated features and its ease of operation make it an ideal choice for applications that require both precise accuracy and rapid production times.

There are no reviews yet