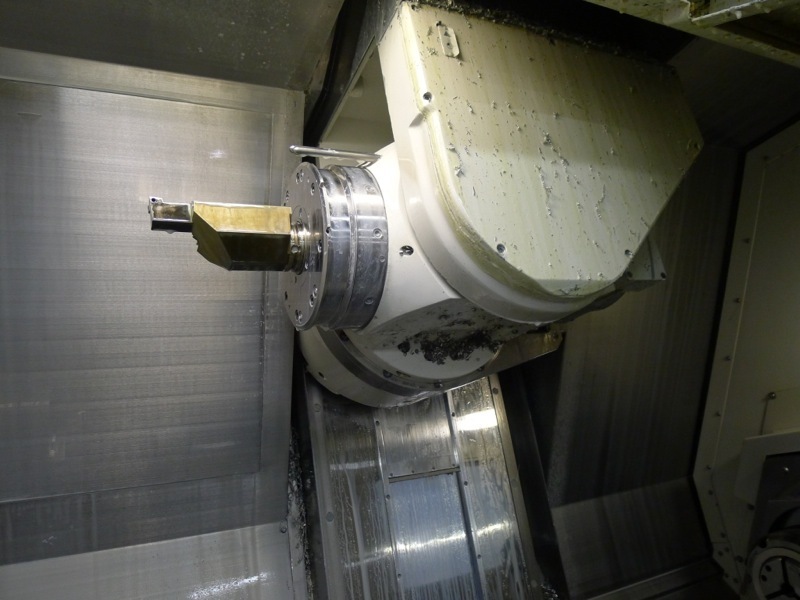

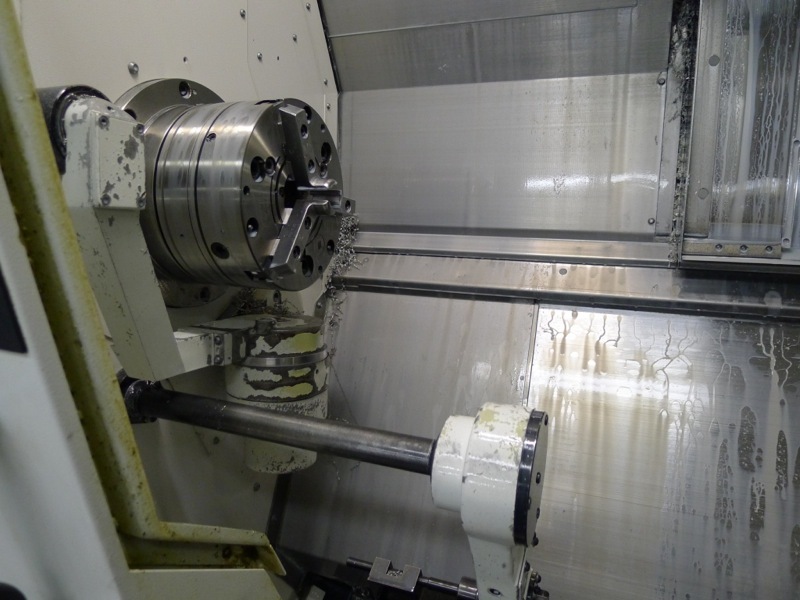

Used MAZAK Integrex 200-IVS #191439 for sale

URL successfully copied!

Tap to zoom

ID: 191439

Vintage: 2007

Multi-axis CNC turning center

Standard specifications:

Standard chuck dia. Main spindle (l): 8"

Standard chuck dia. Second spindle (r): 8"

Maximum swing: 26"

Maximum cutting diameter: chucking: 26" (upper)

Maximum cutting length: 40"

Main spindle specifications (l):

Spindle nose: A2-6

Maximum bar work: 2.5"

Spindle speed: 35 - 5000 rpm

Spindle index (c-axis - programmable): 0.0001 degree

Spindle horsepower (cont./30 mins.): 20/30 h.P. (a.C.)

Second spindle specifications (r):

Spindle nose: A2-6

Maximum bar work: 2"x 34.6" deep

Spindle speed: 35 - 5000 rpm

Spindle index (c-axis - programmable): 0.0001 degree

Spindle horsepower (cont./30 min.): 20/25 hp (a.C.)

Magazine capacity: 40 tools

Max. Tool dia. W/all pockets full: 3.54"

Max. Tool length (from gage-line): 11.81"

Atc tool shank: Mazak km63

Rotary tool spindle speed.: 12,000 rpm

Rotary tool spindle horsepower (20% ed): 25 h.P.

B-axis index 5 degree(coupling clamp)

Movement stroke x: 22.83"

Movement stroke y: 6.3"

Movement stroke z: 41.14"

Movement stroke w: 41.33"

Axis rapid rates:

Y-axis: 1024 ipm

X/x2 axis: 1496 ipm

Z/z2 axis: 1496 ipm

C-axis: 555 rpm

Total power required: 78.7 kva

Equipped with:

Mazatrol matrix cnc control

40 tool km magazine

Tool eye (automatic)

15kg/213 psi thru spindle coolant

Automatic parts catcher w/ejec (2.5" diameter x 4.7"l x 5.5 lb)

Auto chuck jaws open/close (1&2 spindle)

Side exit hinge type chip conveyor

Auto power off

Operation end buzzer

Operator door interlock with lock-switch

Hydraulic pressure interlock

Signal tower yellow light

15" color lcd

Eia/iso code input function

C1-c2 synchronous operation function

3d coordinate conversion

Goo slope constant

Shape compensation for rotary axes

Cylindrical (g07) & polar coordinate(g12)

Milling spindle synchronous tapping

Inch/metric conversion

Cardbus i/f (2-slot)

Lan port

Usb i/f

Y-axis control

Barfeed interface

Windows xp operating system for mazak machine control

Complete set of manuals

Kmz holders:

Turning (rh); qty:10

Turning (lh); qty:3

Boring holder; qty: 13

Er16 collet holder; qty: 16

Er32 collet holder; qty 17

Chucks:

(2) 8" chucks

(1) microcentric cb-65 chuck

Bar feeder:

Lns quick load servo 65

2007 vintage.

MAZAK Integrex 200-IVS is a multi-axis, simultaneous turning and milling CNC machine tool produced by Yamaaki MAZAK Corporation. This highly efficient, flexible machine tool was designed to provide maximum productivity in a compact, user-friendly design. It has a rigidity-enhanced frame and expanded Y-axis that gives operators the ability to complete a variety of complex operations. MAZAK INTEGREX 200 IVS is capable of supporting multi-tasking operations such as milling, turning, drilling, tapping and boring on a single setup. The rotary B-axis allows for 5-axis simultaneous machining, while the integrated tailstock can accommodate long lengths of cylindrical material. The machine has three spindles that are all capable of independently rotating at high speeds to serve multiple processes simultaneously. The integrated spindle motor helps with faster cutting by providing low-energy, high torque performance. The machine tool is equipped with a multi-functional control panel for easy operation. It supports advanced five-axis digitalized programming for fast, precise machining. It has built-in coolant systems, a tool changer with a storage capability of up to 40 tools, and a PSM (programmable spindle mode) that offers a wide variety of spindle control modes. The machine also comes with a chip conveyor system, maintenance alarms, and a foot switch, making it easier for operators to monitor the process. Additionally, Integrex 200-IVS is equipped with MAZAK IMC (Intelligent Machine Control) technology which helps reduce set-up times and machining errors while improving machining quality. The IMC is capable of data logging, quality control data, supporting real-time management, and displaying machine condition indicators. The machine also features a turret indexing time of just 0.15 seconds and rapid traverse rate of 24,000mm/min, allowing for faster and more accurate processing. Overall, INTEGREX 200 IVS machine tool is a highly efficient and user-friendly tool that offers maximum productivity in a compact design. Featuring innovative cutting technologies and advanced programming, the machine tool provides optimized machining, precision, and accuracy in a variety of different operations.

There are no reviews yet