Used MAZAK Integrex 200-IVS #9316531 for sale

URL successfully copied!

Tap to zoom

ID: 9316531

Vintage: 2011

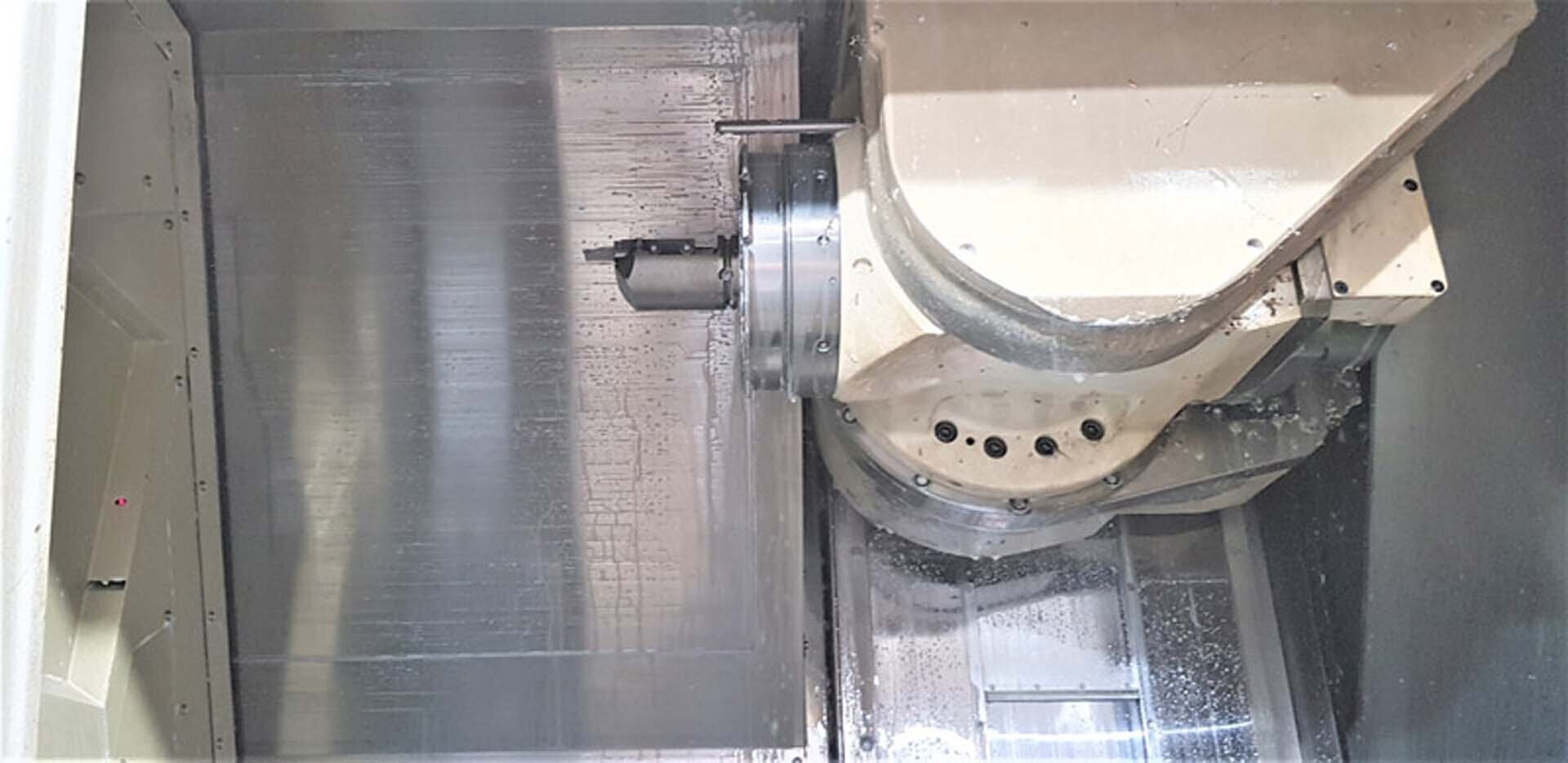

CNC Turning / Milling center

With sub-spindle and Y-axis

Maximum swing: 26"

Maximum swing over carriage: 19.5"-26"

Maximum chucking cutting diameter: 26"

Maximum cutting length: 40"

Maximum distance between standard chuck faces: 41.14"

Main spindle specifications (L):

Spindle nose: A2-6

Spindle bore: 2.99"

Maximum bar work: 2.0"

Spindle speed: 35 - 5,000 RPM

Spindle index (Programmable): 0.0001°

Spindle horsepower (Cont./30 Mins): 20/30 H.P. (A.C.)

Spindle torque (25% ED): 344.2 Ft-lbs

Right spindle specifications:

Spindle nose: A2-6

Spindle bore: 2.99"

Maximum bar work: 2" x 34.6" Deep from chuck face

Spindle speed: 35 - 5,000 RPM

Spindle index (Programmable): 0.0001° (C-Axis )

Spindle horsepower (Cont./30 min): 20/25 HP (A.C.)

Spindle torque (30 Min): 241 Ft-lbs

Turret and tooling specifications:

Type of turret: 1 Position

With ATC

Tool shank height: 1.0"

Boring bar maximum diameter: 1.5"

Magazine capacity: 40 Tools

Tool selection method: Random

Tool to tool ATC time: 1.3 Sec

Maximum tool diameter with all pockets full: 3.54"

Maximum tool diameter with adjacent pockets empty: 4.92"

Rotary tool spindle speed: 12,000 RPM

Rotary tool spindle horsepower (20% ED): 25 H.P. (A.C.)

Rotary tool torque (20% ED): 88.2 Ft-lbs

Maximum face mill: 4"

Maximum end mill: 1.25"

Maximum drill: 1.18"

Maximum tap: 1-8 UNC

Axis travels:

B-Axis: 225°

Y-Axis: ± 3.15"

X-Axis: 22.83"

Z-Axis: 41.14"

Second headstock W-axis: 41.34"

Axis rapid rates:

Y-Axis: 1024 IPM

X-Axis: 1496 IPM

Z-Axis: 1496 IPM

Second headstock W-axis: 1181 IPM

C-Axis: 555 RPM

Equipped with:

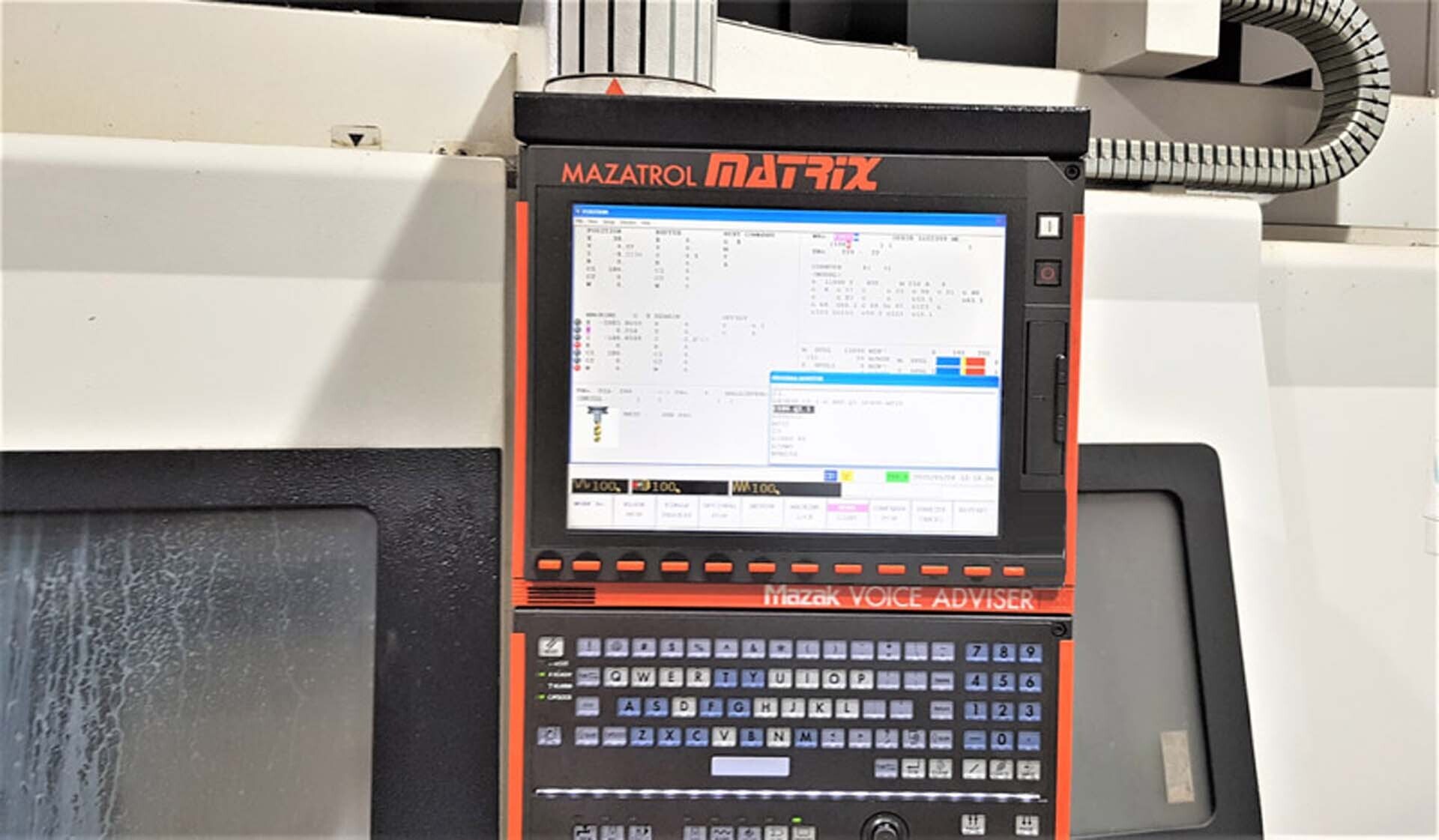

MAZATROL Matrix control

15" Color LCD

Spindle motor: AC 22 kW(30HP)

Spindle position 0.001° without C-axis

3-D coordinate conversion

5kg Thru clnt/flood clnt simul-flowable

8" Thru-hole chuck B-208a615 (1st spindle)

8" Thru-hole chuck B-208a615 (2nd spindle) absolute positioning sys (Linear axes) accuracy inspection

Active vibration control

Air requirements: 71 PSI / 24.7 CFM

Power requirements: 63 kVA

2011 vintage.

MAZAK Integrex 200-IVS is a high-precision three-axis multi-tasking CNC machine tool designed to enhance productivity for a range of industries. This robust and reliable turn-mill center provides a wide range of CNC machining capabilities to produce complex parts complete in one setup. The versatile design of MAZAK INTEGREX 200 IVS machine is capable of milling, turning, boring, drilling, tapping, and API (Automated Part Identification) as well as adding EDM in one operation. It is capable of working on a variety of materials such as mild steel, aluminum, brass, copper, and stainless steel. Integrex 200-IVS features solid Meehanite castings for thermal stability in high-speed machining applications. It also features pressurized lubrication to reduce maintenance and wear and tear and help extend the service life of the machine. Offering outstanding axis travels of 200 x 488 mm, INTEGREX 200 IVS can handle jobs with large diameters, lengths, and heights. Additionally, its spindle bore is a generous ø65 mm, allowing users to process large, heavy parts easily. The CNC capabilities of MAZAK Integrex 200-IVS ensure predictable results with fast setup times. This machine is equipped with a Mazatrol SmoothX Series CNC controller with a 24-inch color touchscreen interface, offering an intuitive tool selection. The controller is also equipped with a 2.2GHz 6-core Intel Core i7 processor for fast calculations. For added convenience, this machine also operates on a variety of standard CAD/CAM packages. MAZAK INTEGREX 200 IVS is the perfect choice for users looking to maximize churn rate and efficiency with a single setup machining solution. Combining highly accurate milling and turning capabilities with improved cycle times and capacities, this machine offers unparalleled performance and productivity for a variety of manufacturing applications. With high dynamic accuracy and a flexible B-axis for easy 5th-axis machining, this machine tool provides the perfect solution for any modern manufacturing facility.

There are no reviews yet