Used MAZAK Integrex 200-IVST #9316430 for sale

URL successfully copied!

Tap to zoom

ID: 9316430

Vintage: 2010

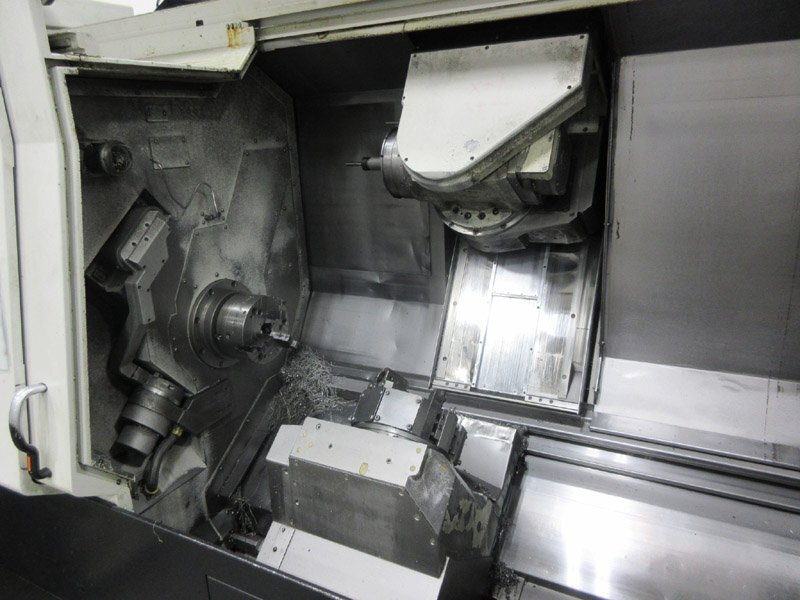

CNC Turning / Milling center

Maximum swing: 26"

Maximum swing over carriage: 19.5" -26"

Maximum swing over lower turret, 10.6"

Maximum distance between chuck jaws: 60"-60.83"

Maximum cutting diameter:

Upper chucking: 26"

Lower chucking: 10.24"

Main spindle (L):

Spindle nose: A2-6

Spindle bore: 2.99"

Maximum bar work: 2"

Spindle speed: 35 - 5000 RPM

Spindle index (Programmable): 0.0001°

Spindle horsepower (Controller/30 Mins.): 20/30 H.P. (A.C.)

Spindle torque (25% ED): 344.2 ft-lbs

Second spindle (R):

Spindle nose: A2-6

Spindle bore: 2.99"

Maximum bar work: 2"x 34.6" Deep from chuck face (2" thru optional)

Spindle speed: 35 - 5000 RPM

Spindle index (Programmable): 0.0001° C-Axis

Spindle horsepower (Controller/30 Min): 20/25 HP (A.C.)

Spindle torque (30 min.): 241 ft/lbs

Upper turret and tooling:

Type of turret: 1 Position with ATC

Tool size (Boring bar maximum diameter): 1.5"

Magazine capacity: 40 Tools

Tool selection method: Random

Tool to tool ATC time: 1.3 Sec

Maximum tool diameter with all pockets full: 3.54"

Maximum tool diameter with adjacent pockets empty: 4.92"

ATC Tool shank: KM63

Rotary tool spindle speed: 12,000 RPM

Rotary tool spindle horsepower (20% ED). 25 H.P. (A.C.)

Rotary tool torque (20% ED): 88.2 ft-lbs

Maximum face mill: 4"

Maximum end mill: 1.25"

Maximum drill: 1.18"

Maximum tap: 1-8 UNC

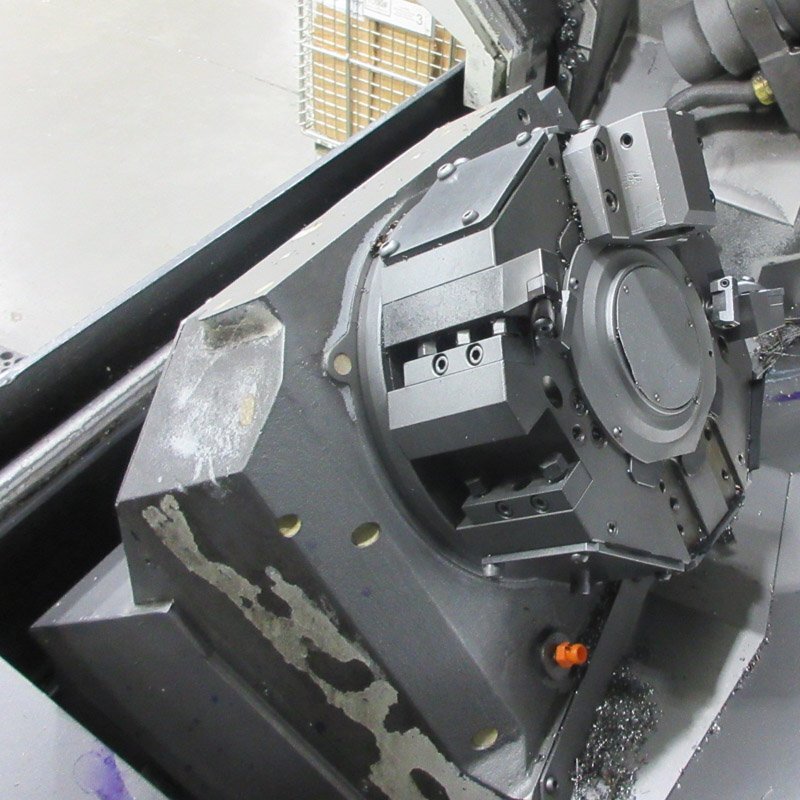

Lower turret and tooling:

Type of turret: Drum

Boring bar maximum diameter: 1.25"

(9) Tools (6 Rotary)

Tool selection method: Bi-directional

Tool index time: 0.14 Sec

Lower turret with milling option rotary tool spindle

Speed: 6,000 RPM

Rotary tool spindle horsepower: (10% ED), 5 H.P. (A.C.)

Rotary tool torque for 6,000 RPM: 11 Ft/Lbs

Maximum drill: 4,500/6,000 RPM, 14/12 mm

Maximum tap: 4,500/6,000 RPM, M12/M10

Axis travels:

B-Axis: 225°

Y-Axis: ±3.15"

X-Axis: 22.83"

Z-Axis: 60"-60.82"

X2 Axis lower-5.91"

Z2 Axis lower: 60"-58.66"

Second headstock W-axis: 60"-61.02"

Axis rapid rates:

Y-Axis: 1024 IPM

X-Axis: 1496 IPM

Z-Axis: 1496 IPM

Second headstock W-axis: 1181 IPM

C-Axis: 555 RPM

Total power required (Machine only): 76.5 kVA

Air requirements: 71 PSI / 24.7 CFM

Equipped with:

MAZATROL Matrix control

Color LCD, 15"

EIA/ISO Code input function

3-D Coordinate conversion

GOO Slope constant

Shape compensation for rotary axes

Cylindrical and polar coordinate

Milling-spindle synchronous tapping

IC Memory card interface

Inch/Metric conversion

Cardbus I/F (2-Slot)

LAN Port

USB I/F

X, Y, Z Pitch error compensation input

Y-Axis control

KM Type upper turret

Lower turret with milling

Coolant thru milling head

213 PSI Thru / Clood coolant upper turret / 71 PSI Lower

C-Axis 0.0001° Incr. (1St spindle)

2nd Spindle C-axis 0.0001° Incr

Chuck air blast (2nd Spindle)

40 KM Tool magazine

Rotary tool spindle speed: 12,000 RPM

B-Axis 0.0001° / Cntring (Req. EIA/ISO)

B-Axis index 5°(Coupling clamp)

Lower 9 positions drum turret

Chip conveyor side disposal (Hinge type), 60” 1500U

Automatic tool eye

Auto chuck jaws open / Close (1 and 2 Spindle)

Chuck open / Close confirm (1 and 2 Spindle)

Relocation device

Operating system: Windows XP for MAZAK machine control

Overload detection system

Auto pecking with load detection (Up-turret)

C1C2 Synchronous function

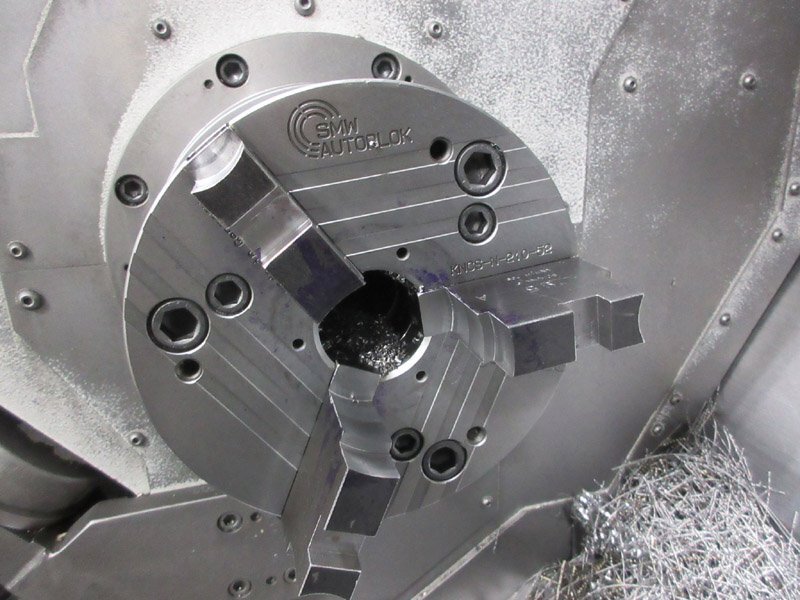

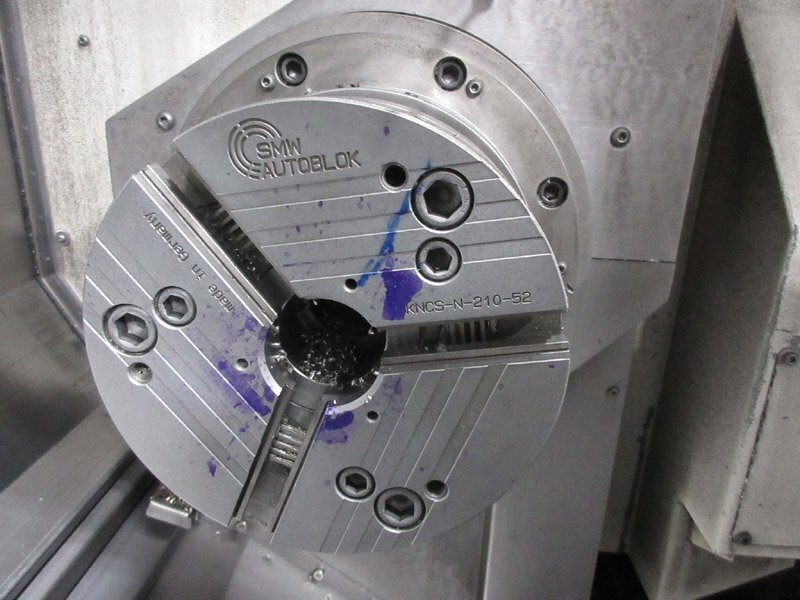

GL150F / Pitch-feed type 2 / D3-hand / Jaw-AB

Maximum workpiece: 0.79"-7.87" diameter x 4.72" L

Lower turret milling function: 6000 RPM

(6) Pallet pitch feed conveyors type 2

Robot interface

Auto GL door open / Close (air cylinder)

Safety fence

(2) SMW Autoblok, 8" chucks

~ (50) KM63 Holders included

2010 vintage.

MAZAK Integrex 200-IVST is a high-precision, multi-functional machine tool designed to help fabricators create complex parts more efficiently. The equipment features an advanced CNC/spindle combination to offer maximum chipping power, maximum accuracy, and improved productivity. The unique design of MAZAK INTEGREX 200IV ST enables users to easily switch between multiple operations with the ability to perform a variety of tasks. The machine features an eight-axis version of MAZAK Multiplex series of CNC. It also includes specially designed spindle heads with a 5-axis simultaneous spindle. This spindle gives users the ability to perform dual-processing on parts in one set-up, which is useful for complex parts that require multiple operations. The system comes standard with a Mazatrol 840 CNC controller which provides ease of operation and high precision when completing a job. It is equipped with a range of diverse functions, such as centralized lubrication, air blast separation, auto stuffing, spindle bevels grinding, integrated auto square, and much more. The Integrex can be set up with numerous features and accessories to further increase user productivity, including tool changers, chip conveyors, automatic pallet changers, and quality control systems. For added accuracy and performance, Integrex 200-IVST is equipped with a thermal stability unit with laser calibration and quartz encoder positioning. This machine ensures that the machine remains stable in any environment, allowing for more accurate parts production. The machine also features an adjustable spindle nut torque to provide reduced vibration and improve cutting performance. INTEGREX 200IV ST delivers high-precision results, enhanced performance, and increased productivity. With its advanced CNC/spindle combination, multiple features, and adjustable spindle nut torque, the Integrex is a great tool for any fabricator who needs to create complex parts with the highest degree of accuracy and speed.

There are no reviews yet