Used MAZAK INTEGREX 300-3ST #9277147 for sale

URL successfully copied!

Tap to zoom

ID: 9277147

Vintage: 2005

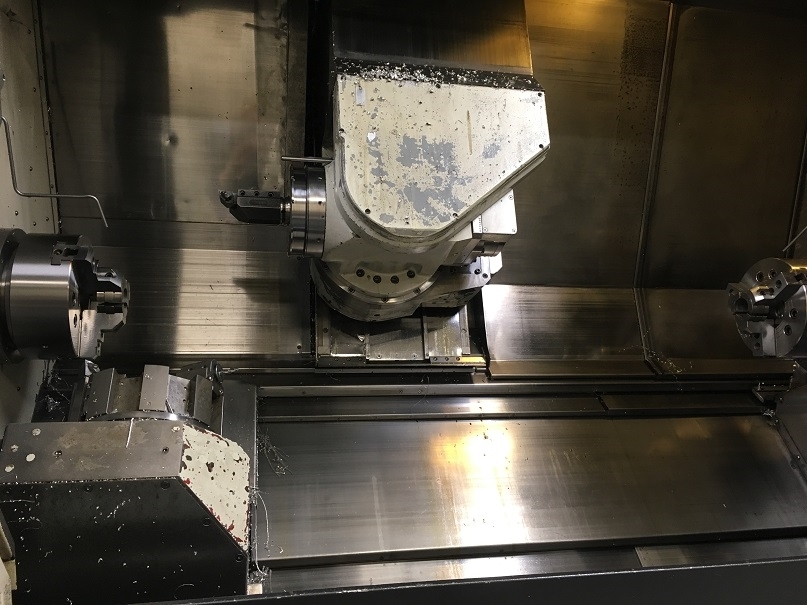

Multi-axis CNC turning center

MAZATROL Fusion 640MT PRO CNC

Floppy Disc Drive (FDD): RS-232 C / 3.5"

PCMCIA I/F (2-Slots, card bus)

Network interface (For LAN and MODEM)

Coolant thru milling head

Flood coolant: 213 PSI Thru (Upper Turret)

Flood coolant: 14.2 PSI / 1KG (Lower turret)

C-Axis: 0.0001° (1st Spindle)

2nd Spindle position: 0.001° without C-axis

Tool magazine: 40 KM

B-Axis: 0.0001° N/A contouring

B-Axis: Index 5° (Coupling clamp)

Lower 9-positions drum turret

Chip conveyor (Side, consep): 1500U (60")

Automatic tool eye

Auto chuck jaws open / Close (1 and 2 Spindle)

Chuck open / Close confirm (1 and 2 Spindle)

Chuck air blast (1st Spindle)

(2) KITAGAWA Chucks, 10"

Maximum swing: 33.5"

Maximum swing using Y-Axis: 26"-33.5"

Maximum swing over cross slide: 33.5"

Maximum swing over lower turret:16.5"

Without boring bar holder on turret

Maximum cutting diameter: Chucking, 30" (Upper)

Maximum cutting diameter: Chucking, 16.5" (Lower)

Maximum cutting length: 60"

Maximum distance between chuck faces: 60"

Main spindle (L):

Spindle nose: A2-8

Spindle bore: 3.46"

Maximum bar work: 3.0" Dia

Spindle speed: 4,000 RPM

Spindle index (Programmable): 0.0001°

Spindle horsepower (Cont/30 Mins): 30/35 HP (AC)

Spindle torque: 442.5 ft-lbs

Second spindle (R):

Spindle nose: A2-8

Spindle bore: 3.46"

Maximum bar work (Non-thru): 3.0" Diameter

Spindle speed: 4,000 RPM

Spindle index (Programmable): 0.001°

Spindle horsepower (Cont./30 Min.): 30/35 HP (AC)

Spindle torque: 368.8 ft-lbs

Upper turret and tooling:

Turret position with ATC

Tool shank height: 1"

Tool size (Boring bar Maximum diameter): 1.5"

Magazine capacity: 40 Tools (KM)

Tool selection method: Random

Tool to tool ATC time: 1.3 Sec

Maximum tool diameter with all pockets full: 3.54"

Maximum tool diameter with adjacent pockets empty: 4.92"

Maximum tool length (From gage-line): 15.75"

Rotary tool spindle speed: 12,000 RPM

Rotary tool spindle horsepower (20%ED): 24.8 HP (AC)

Rotary tool torque (20%ED): 88.5 ft-lbs

Lower turret and tooling:

Turret: Drum

Tool shank height: 1.0" x 1.0" x 5"L

Tool size (Boring bar maximum diameter): 1.25"

(9) Tools

Tool selection method: Bi-Directional

Tool index time (1 Step): 0.14 Sec

Axis travels:

Y-Axis: +/- 4.53"

X-Axis: 24.8"

Z-Axis: 62.4"

X2 Axis lower: 9.06"

Z2 Axis lower: 60.2"

Second headstock W-axis: 60.24"

Axis rapid rates:

Y-Axis: 1023 IPM

X/X2 Axis: 1496 IPM

Z/Z2 Axis: 1496 IPM

Second headstock W-axis: 1181 IPM

C-Axis: 400 RPM

B-Axis: 10 RPM

2005 vintage.

MAZAK INTEGREX 300-3ST is a multi-tasking machine tool that is perfect for manufacturing complex components with sophisticated features that require high accuracy and precision. It is equipped with a "Pallet Pool" function that allows for easy and efficient pallet exchange for load in/load out. This increases production flexibility, as components can be quickly unloaded and a new pallet loaded, all without interruption to machining operations. The machine includes 3 independent spindles - a main spindle, rotary tool spindle, and counter spindle. The main spindle features high power cutting capability up to 2200 rpm and 42 kW high torque cutting. This allows for higher cutting speeds when machining difficult materials. The rotary tool spindle can also reach up to 2200 rpm and is perfectly suited for milling and face machining operations. The counter spindle can reach up to 6000 rpm and also features a high torque cutting capability up to 14 kW, allowing for repeatability and precision for small workpieces. The machine is also equipped with a powerful CNC control equipment that is capable of handling multiple tasks simultaneously. This allows for complex component machining and shorter cycle times. The CNC control can also process data relevant to the component program, such as dimensions, tolerances, and cutting conditions with a high degree of accuracy. The machine is also equipped with a powerful 12-axis system that allows for three simultaneous operations. This includes 3 axes that are servo-driven for precision and accuracy, 3 axes simultaneously controlled for motion control, 2 axes for motion control simultaneous with machining, and 4 axes for complex part machining. The 12-axis unit increases production efficiency as it can reduce set-up time and shorten machining cycle times. INTEGREX 300-3ST also features a variety of coolant delivery systems, such as a high-pressure machine, an intermittent tool, and an oil mist asset. This allows for efficient cooling of the cutting area and improved chip control, which is especially important when machining high-strength material. The machine also includes an automatic tool magazine with the capacity to store up to 40 tools, allowing for quick and efficient tool changes. This helps to reduce cycle times and increases machine utilization. Overall, MAZAK INTEGREX 300-3ST is a powerful and efficient machine tool that is perfect for manufacturing complex components with sophisticated features. It is equipped with powerful motor spindles, a high-performance CNC control model, a 12-axis equipment for three simultaneous operations, and a variety of coolant delivery systems. Additionally, it has an automatic tool magazine with the capacity to store up to 40 tools, allowing for efficient tool changes and improved production efficiency.

There are no reviews yet