Used MAZAK Integrex 30Y 1000 #9036400 for sale

URL successfully copied!

Tap to zoom

ID: 9036400

Vintage: 1997

Universal CNC Turning and Milling center

Specifications:

Maximum swing: 22.64"

Swing over cross slide: 18.5"

Distance between centers: 40.08"

Spindle head center height: 12.2"

Max. chucking capacity including chuck: 550 lbs

Maximum capacity between centers including chuck: 2200 lbs

Main motor (cont. per 30 - minute rating): AC 22 / 30 kW

Milling motor (cont. per 10 - minute rating): AC 2.2 / 7.5 kW

Rapid traverse rates: X - 472.44, Z - 708.66, Y - 454.61, C - 100 IPM

Maximum turning diameter: 22.64"

Maximum machining length: 40.08"

Spindle bore: 3.46" (current chuck NOT thru-hole)

Minimum spindle index: .001 degree

Spindle speed: 35 - 3000 RPM

Milling spindle speed: 3000 RPM

Milling spindle taper: CAT 40

Tailstock center: MT #5

Includes:

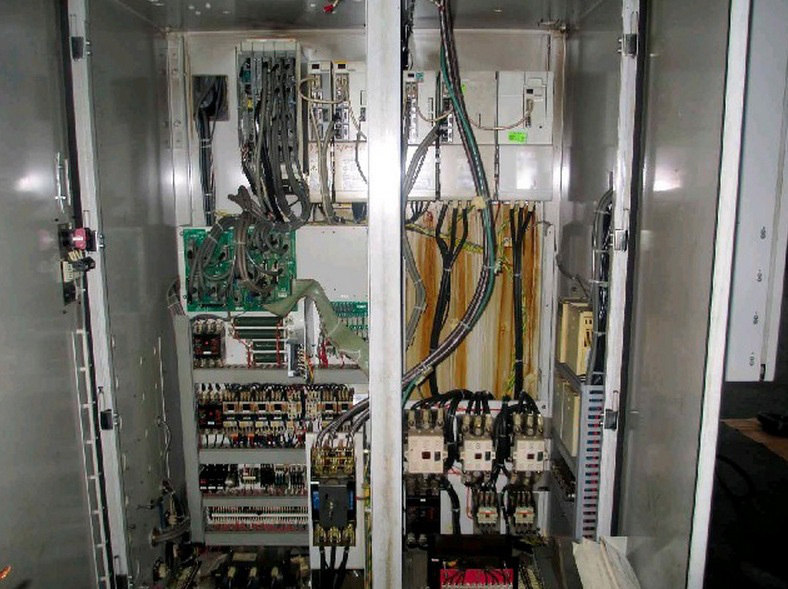

Mazatrol T-Plus control

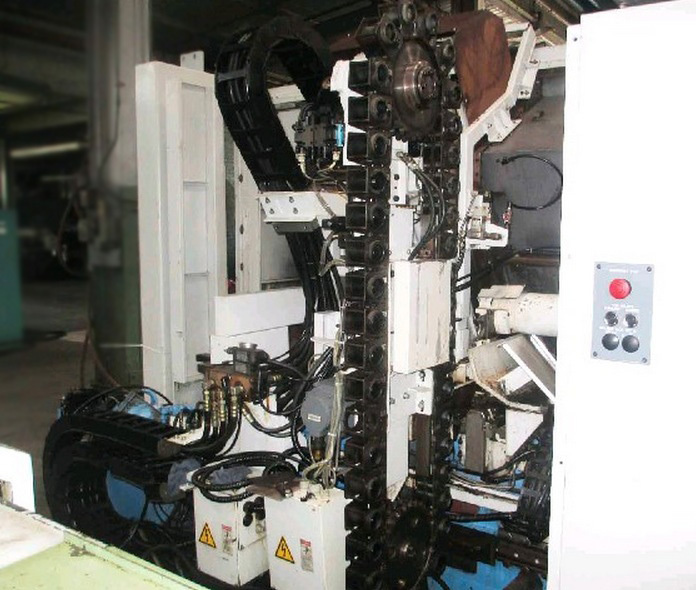

Y-Axis

90° Rotating milling / turning head

40-Position automatic tool changer (20 static / 20 live)

15" 3-Jaw serrated chuck

Tailstock

Approximately 25 assorted static turning tools

Jorgensen chip conveyor / coolant

512 Kb memory

Synchronized tapping card

Tool eye

1997 vintage.

MAZAK Integrex 30Y 1000 is a machine tool used for a wide variety of machining operations, such as drilling, boring, milling, and turning. It is designed for high productivity, accuracy, and repeatability. It is a multi-tasking machine, allowing it to complete entire parts in one setup, which helps to reduce lead times. The machine is equipped with a 1000 mm turning diameter, and a 520 mm cross slide stroke. It is capable of utilizing milling, drilling, and tapping operations. It is equipped with a MAZAK Mazatrol M/Matrix Nexus 2 CNC control, which allows the operator to program complex 3-dimensional parts with ease. Integrex 30Y 1000 has a compound slide Y-axis which provides a lot of advantages when drilling, tapping, and milling operations are necessary. This Y-axis gives the machine tool immense flexibility, because it allows various options for machine components such as extended drill chucks, boring bars, and robotic arms to be attached and used. The machine has a built-in measuring equipment which helps to ensure that the parts are properly aligned and positioned for accurate cutting. This system includes a touch probe and laser that can accurately measure and position the part for optimal cutting results. The machine has an integrated spindle unit motor, which is designed for optimal efficiency in high-speed cutting operations. This built-in motor delivers up to 40,000 RPM and the spindle is equipped with a high accuracy double-contact shaft machine that prevents spindle run-out, which increases machining accuracy. The spindle is further supported by three-way hydrostatic bearings which provide excellent rigidity and dampening for smoother cutting operations. MAZAK Integrex 30Y 1000 has a high speed tool-changing tool which allows for rapid tool changes. This asset can store up to 60 tools which can be moved automatically between the spindle and turret. This feature ensures that the machine can be quickly adapted to different machining requirements and maximize production. Additionally, the machine has a built-in pallet changer which makes it possible to switch from one workpiece setup to another quickly. Integrex 30Y 1000 is a powerful and precise machine tool that allows manufacturers to complete complex parts with minimal setup times. This machine is suitable for machining operations such as drilling, boring, milling, and turning, and is designed to deliver high productivity, accuracy, and repeatability. With its advanced features such as the built-in measuring model, integrated spindle equipment motor, and high speed tool-changing system, MAZAK Integrex 30Y 1000 can help to improve part production quality and reduce lead times.

There are no reviews yet