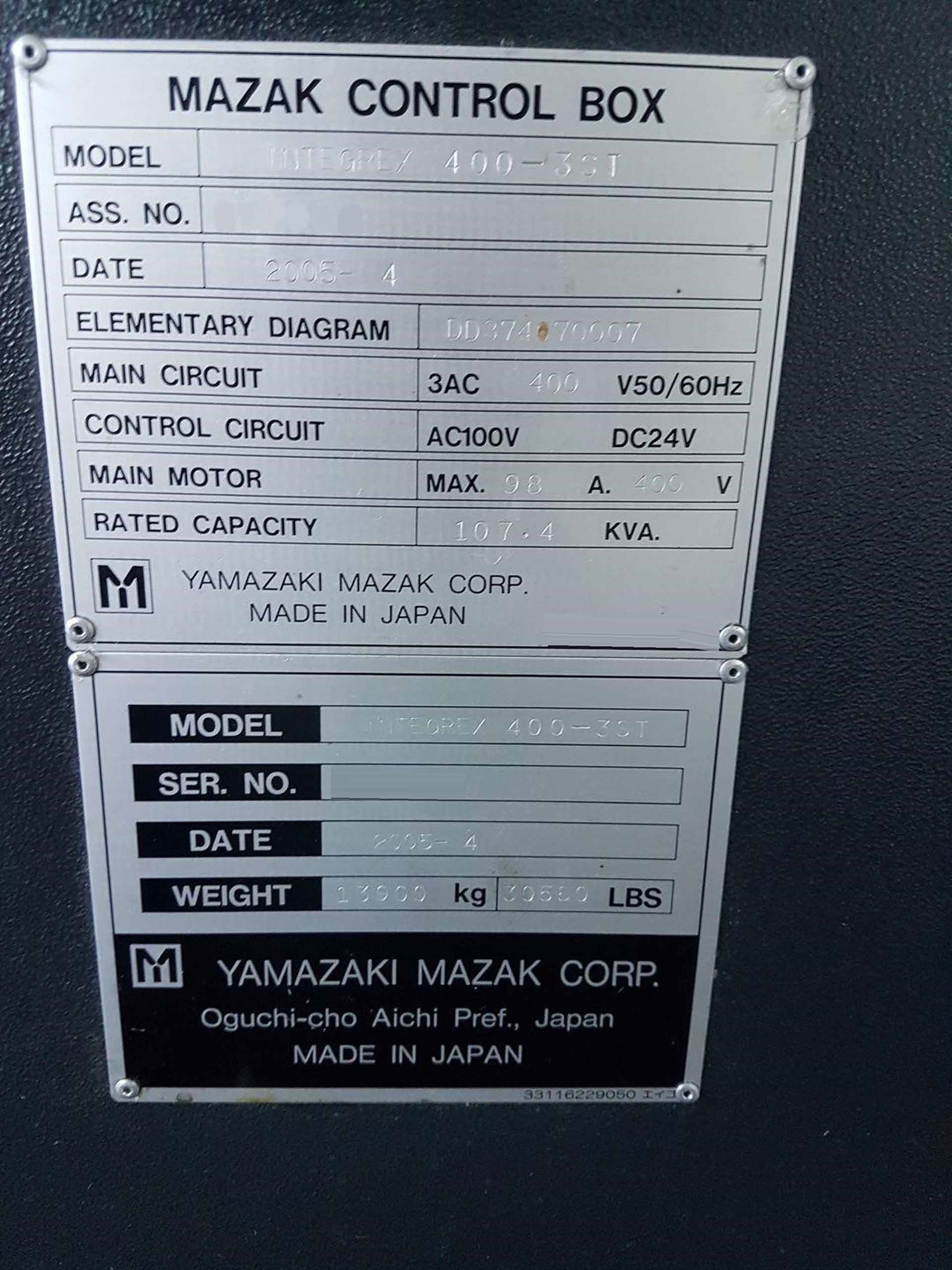

Used MAZAK Integrex 400 III ST #9220127 for sale

URL successfully copied!

Tap to zoom

ID: 9220127

Vintage: 2005

CNC Turning / Milling center

Eqiupped with:

MAZATROL PC Fusion 640 MT

Milling spindle above (B-axis)

Revolver below (9 Places)

2x C-axis

Y-Axis 40 fold magazine

Main spindle: 3 Jaw chuck

Sub spindle: 3 Jaw chuck

Rotary diameter over bed: 29.9213”

Rotary diameter over sledge: 29.9213” Maximum

Maximum turning diameter: 29.9213”

Maximum turning length: 60”

Travel X-axis: 24.8031”

Travel Z axis: 62.40157”

Travel Y-axis: ±9.05512’’

Travel X2-axis: 9.05515’’

Travel Z2-axis: 60.23622’’

Maximum B-axis 225°

Maximum spindle speed: 35-3300 RPM

Tool taper milling spindle CAPTO C6

Maximum speed milling spindle: 12000 RPM

Magazine: 40 Places

Rapid feed X, Y, Z: 38, 26, 38 Minimum

Drive capacity:

Main spindle / Sub spindle: 30 / 26 kW

2005 vintage.

MAZAK Integrex 400 III ST is a high-performance machine tool developed by MAZAK Corporation, a leading global manufacturer of machine tools. This state-of-the-art multi-tasking lathe offers an impressive array of features designed to meet the needs of a wide range of machining and parts production applications. Integrex 400 III ST offers a highly rigid, deeply inclined bed construction, which allows for faster cutting speeds and improved machining precision, while also minimizing vibration. Additionally, the machine's spindle speeds can reach up to 6000 rpm, allowing for faster material processing. The Spindle is equipped with a dual-contact bearing structure that is able to support heavier loads, thus extending the lifetime of the spindle. The machine is equipped with an ultra-high precision drive system, allowing for accuracy levels of +-0.00006" (+-0.0015mm). The Integrex also includes an automatic tool changer, allowing for parts production changes to be completed quickly. Additionally, the machine has an integrated tool measurement system, which assists with tool set up time and allows for a greater degree of precision when operating the machine. The machine also includes a FANUC 31i-MODEL B CNC Control which has a high degree of accuracy and enhanced programming options. It functions effectively even in high-demand situations, allowing for powerful machining simulations which can increase output and reduce design time. MAZAK Integrex 400 III ST is fully integrated with a range of active components such as an Automatic Door Switch, Connectivity Options, Probing Sensors, and a Zero Return Function. These integrate with its a range of other features and functions, delivering a comprehensive, integrated machine set up which is also incredibly user friendly. In addition, the machine is also equipped with MAZAK e-Touch CNC Control Interface. The intuitive, icon-based user experience is designed to greatly reduce training time and enhance users' efficiency and productivity. Integrex 400 III ST is a reliable and incredibly capable machine tool, perfect for a wide range of parts production requirements. Its deep inclination bed construction ensures accurate and efficient jobs with minimal vibration during processing. Furthermore, its FANUC 31i-MODEL B CNC Control, Automatic Tool Changer, and Elevated Speed Spindle all contribute to the efficient production process. Additionally, its e-Touch CNC Control Interface drastically reduces training time and enables powerful machining simulations. All in all, MAZAK Integrex 400 III ST is an excellent machine tool - a great choice for anyone looking to complete a variety of parts production tasks.

There are no reviews yet