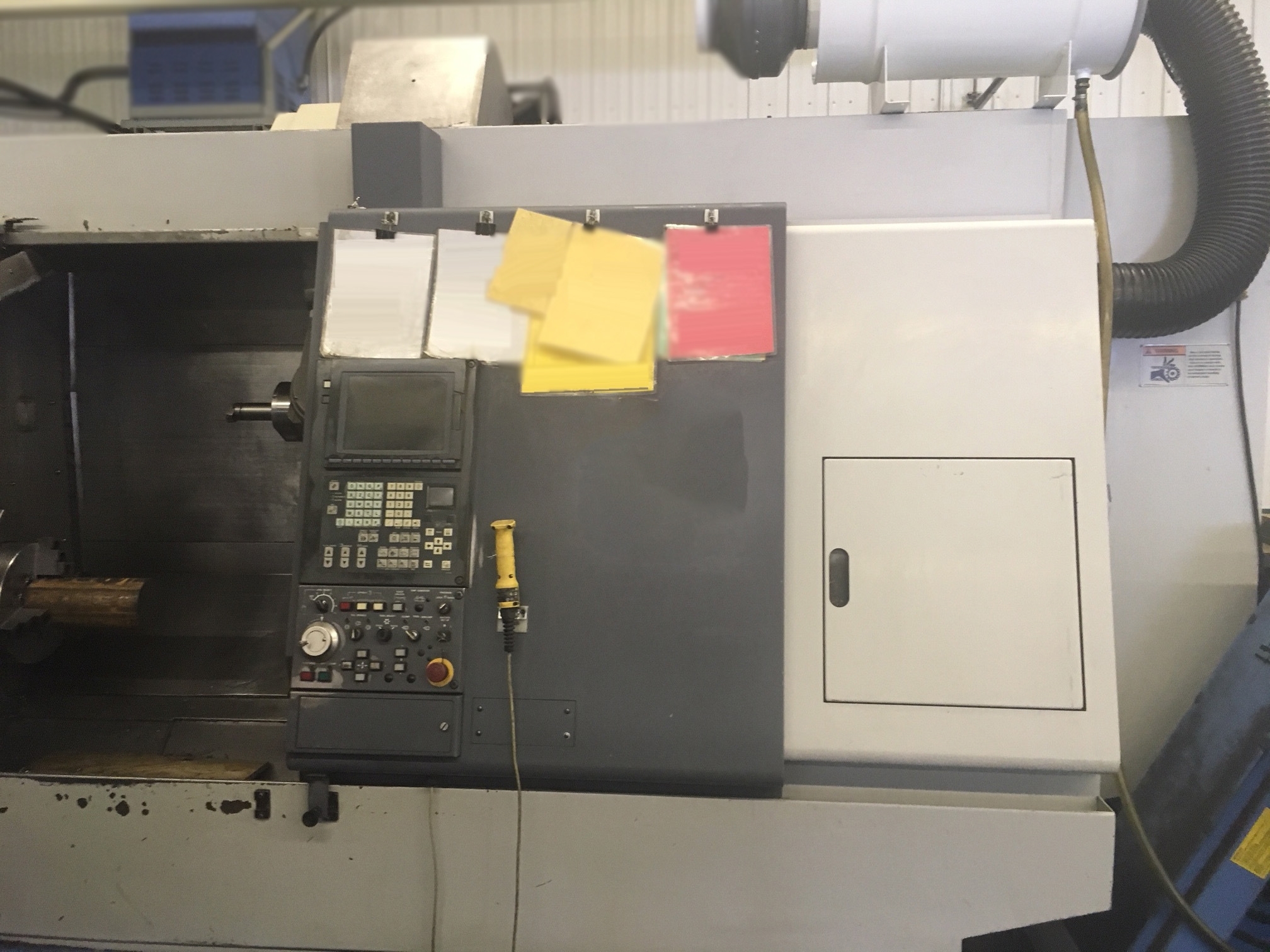

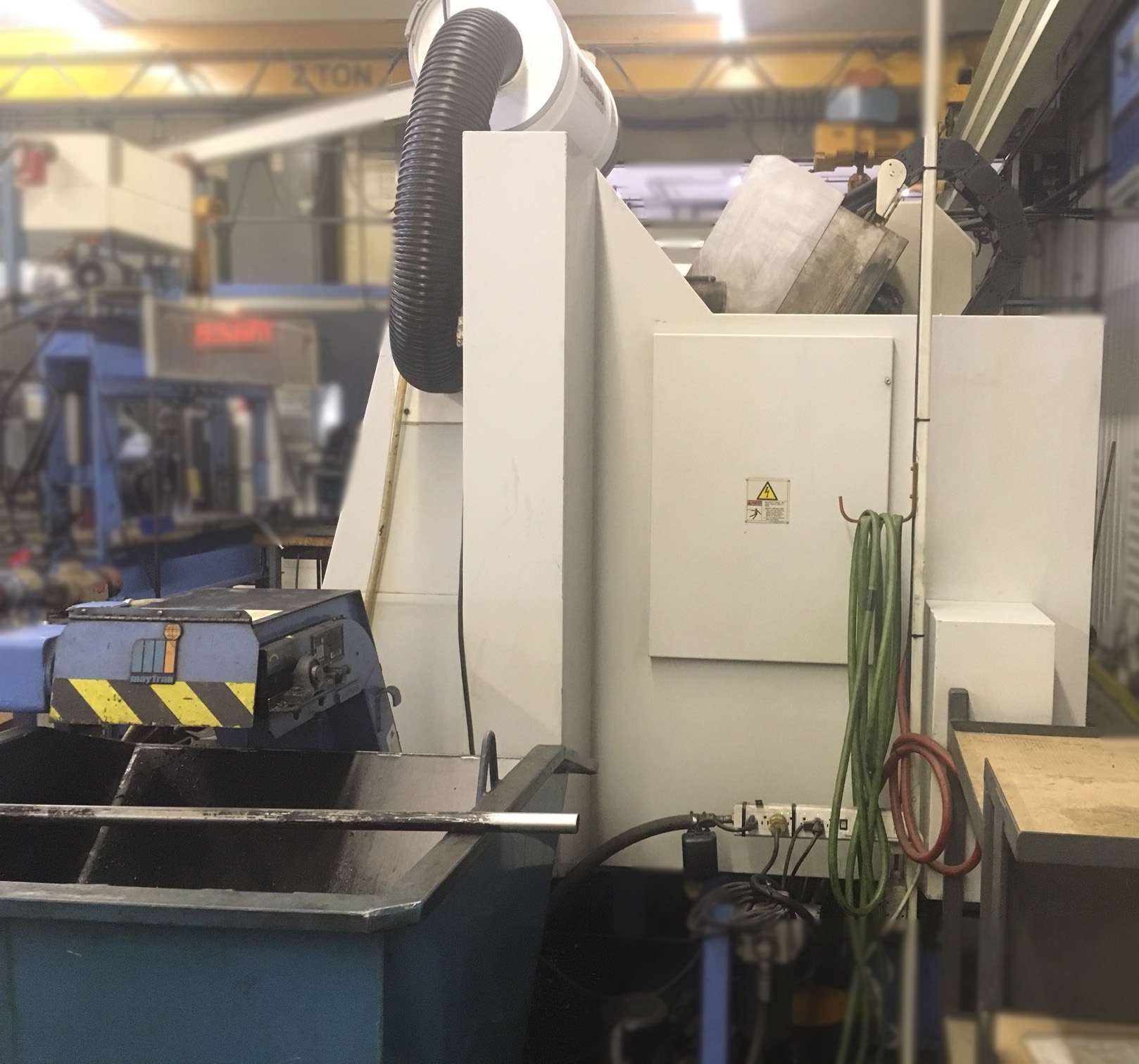

Used MAZAK Integrex 400 Y #9208496 for sale

URL successfully copied!

Tap to zoom

ID: 9208496

Vintage: 1999

Specifications:

Maximum swing: 24.01"

Swing over carriage: 15.35"

Maximum machining length: 40.07"

X-Axis stroke: 22.83"

Y-Axis stroke: 8.26"

Z-Axis stroke: 43.11"

Spindle speed: 3000 RPM

Spindle nose: A2-8

Spindle bore / Bar capacity: 3.46"/ 3"

Minimum spindle indexing increment: 0.001

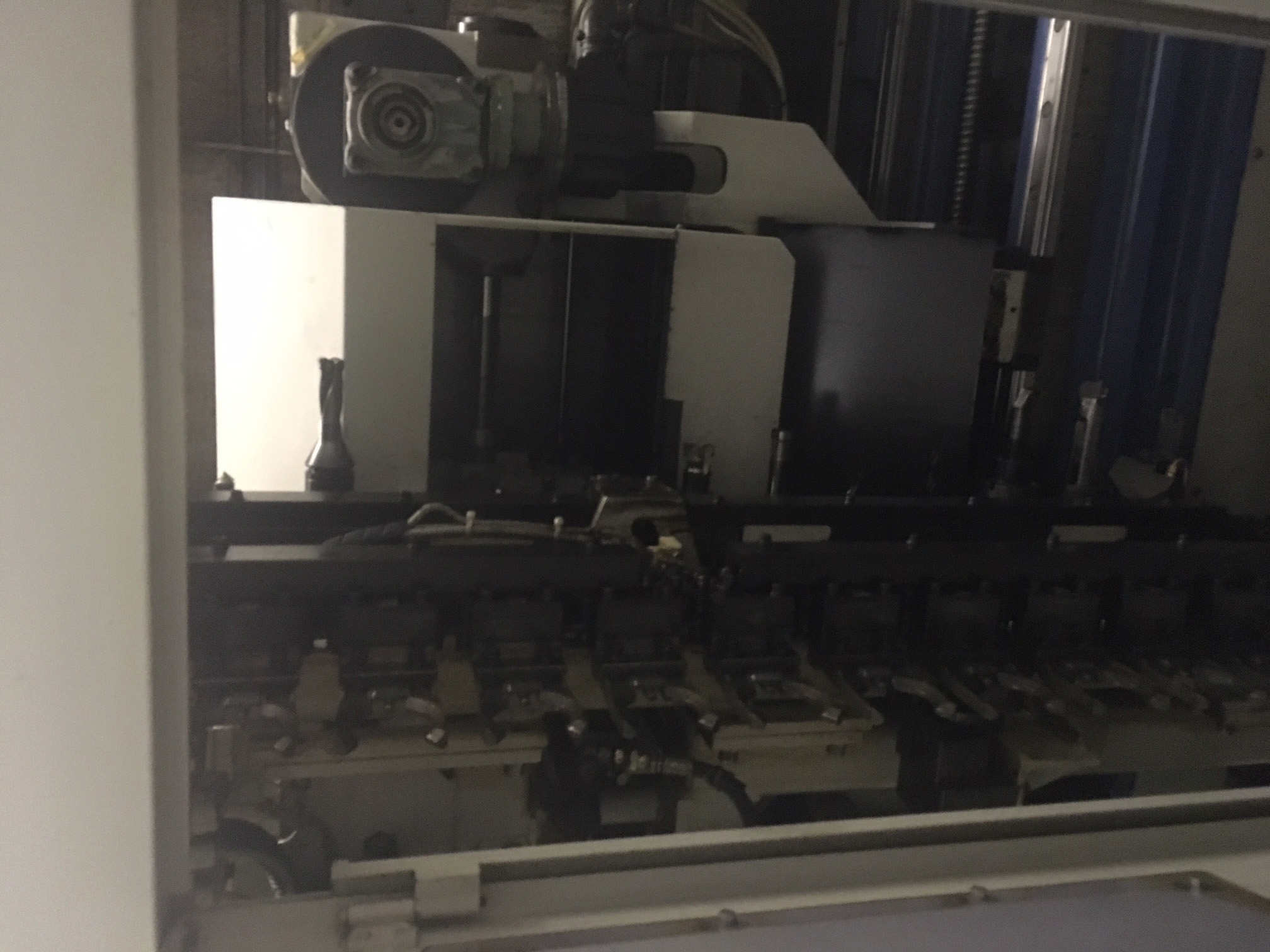

Turret type: Single spindle W/ATC

Tool shank size: 1" Square

Boring bar shank diameter: 1.5 IN

Rotary tool speed range: 6000 RPM

Tool shank configuration-rotary tool: 40

Tool storage capacity: 40 Tools

Maximum tool diameter: 3.54 IN

With adjacent pockets empty: 4.72 IN

Maximum tool length: 11.81 IN

Maximum tool weight: 22 LBS

Tool change time (Tool to tool): 1.3 Seconds

Rapid traverse rate:

X-Axis: 1181 IPM

Y-Axis: 590 IPM

Z-Axis: 1181 IPM

C-Axis: 300 RPM

Jog feedrate (X, Y & Z): 0.04 - 78.74 IPM

Tailstock stroke: 36.22 IN

Tailstock quill stroke: 5.12 IN

Tailstock center: MT # 4

Main spindle motor : AC 30/ 40 HP

Rotary tool motor: AC 20 HP

Floor space requirements: 154.9 IN x 88.6 IN

Equipped with:

Mazatrol fusion: 640

EIA/ISO Option package (for integrex with B-Axis)

Mill spindle sync tap

Coolant through milling head

B Axis .001 deg increment N/A Contouring

Hyd Pressure interlock

40 Tool ATC

KM 63 Tooling

12" SMW KNCS-NB315-91 Hydraulic quick change chuck

X-Axis scale feedback

Chip conveyor (side)

All manuals

Power supply: 50.5 kVA

1999 vintage.

MAZAK Integrex 400 Y is a 5-axis, multi-tasking machine tool manufactured by Yamazaki MAZAK Corporation. This advanced machine, combining milling, drilling, and turning in one setup, is designed with the latest technology in order to help reduce set-up times, improve cycle time accuracy, and provide enhanced machining capabilities. Integrex 400 Y is equipped with a powerful spindle and a wide range of tools, enabling it to perform a range of machining operations in one setup. The spindle features a double-contact roller bearing, providing increased rigidity to enable higher speeds and more accurate positioning during operation. With direct drive motors, the machine is capable of high acceleration and high speeds, up to 3,500 min-1, providing high productivity. The integral 40-tool magazine is capable of holding tools up to 17kg and the machine has an option for up to 60 tools. The machine is fitted with two 12,000 rpm spindle motors that are powered by a 32 bit CPU. These spindle motors enable a maximum power rating of 30 kw and an output torque of 74.4 Nm. The spindle is also designed for high metal removal rate (MRR) and the machine has a maximum traverse rate of 33m/min. In addition, the machine has a wide variety of features to enhance operation, including a Fanuc 15iMB CNC system, intuitive conversational programming, and single-chucking system for easy operation. The conversational programming helps simplify the set up process and allows even novice operators to quickly get the machine up and running. The 15iMB CNC system is also designed to make operations more efficient and has an auto-tuning feature that allows operators to quickly optimize the performance of the machine. MAZAK Integrex 400 Y is designed for both shops where precision and accuracy are paramount, as well as busy production facilities that demand high productivity. Its design ensures easy operation and excellent performance, making it an ideal machine for a wide variety of machining applications. The machine is highly reliable, ensuring reliability during long-term operation. It is also capable of producing excellent surface finishes, making it an excellent choice for machining precision components.

There are no reviews yet