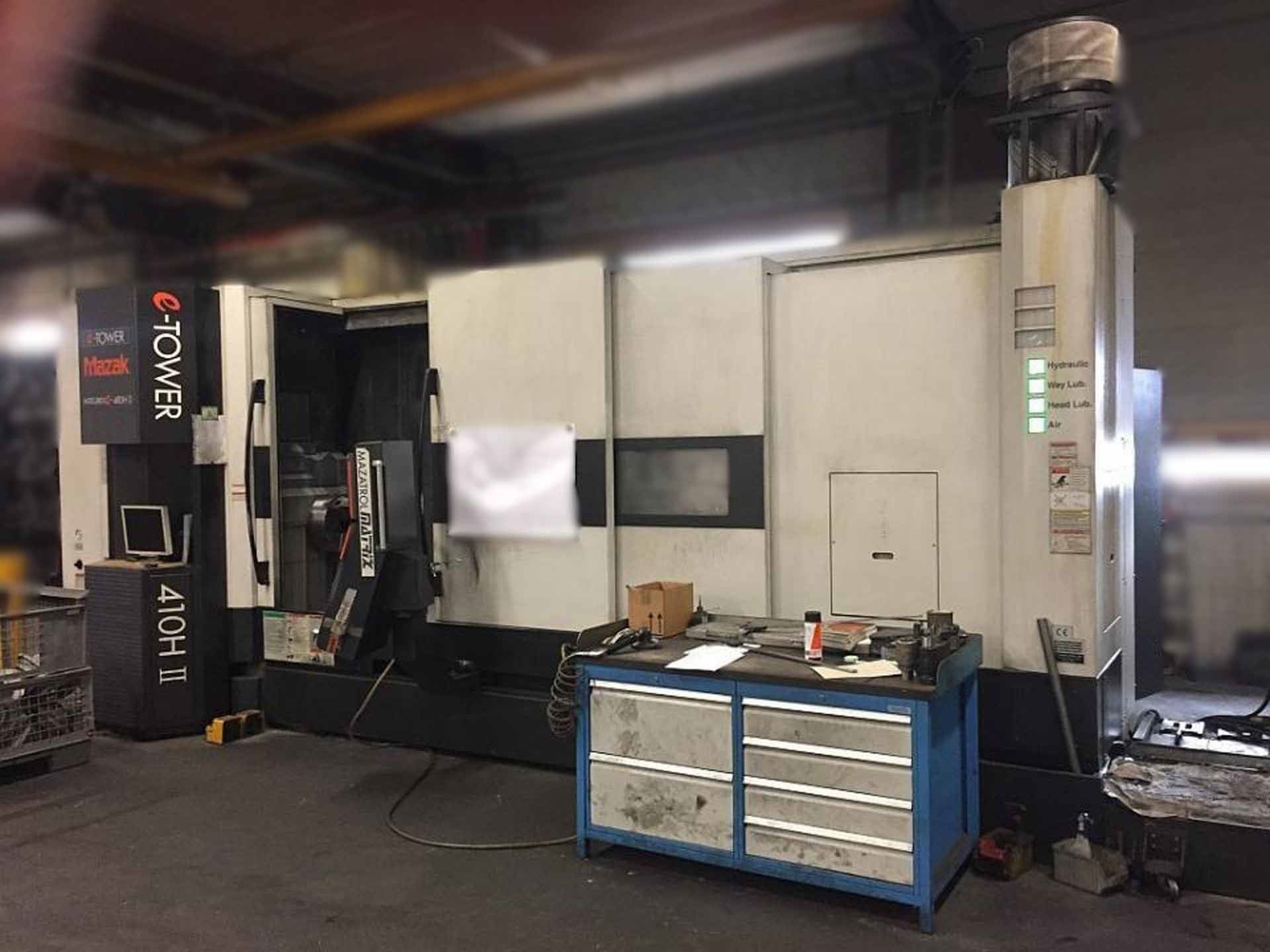

Used MAZAK Integrex e-410H II 3000 #9219926 for sale

URL successfully copied!

Tap to zoom

ID: 9219926

Vintage: 2007

CNC Multi tasking machine

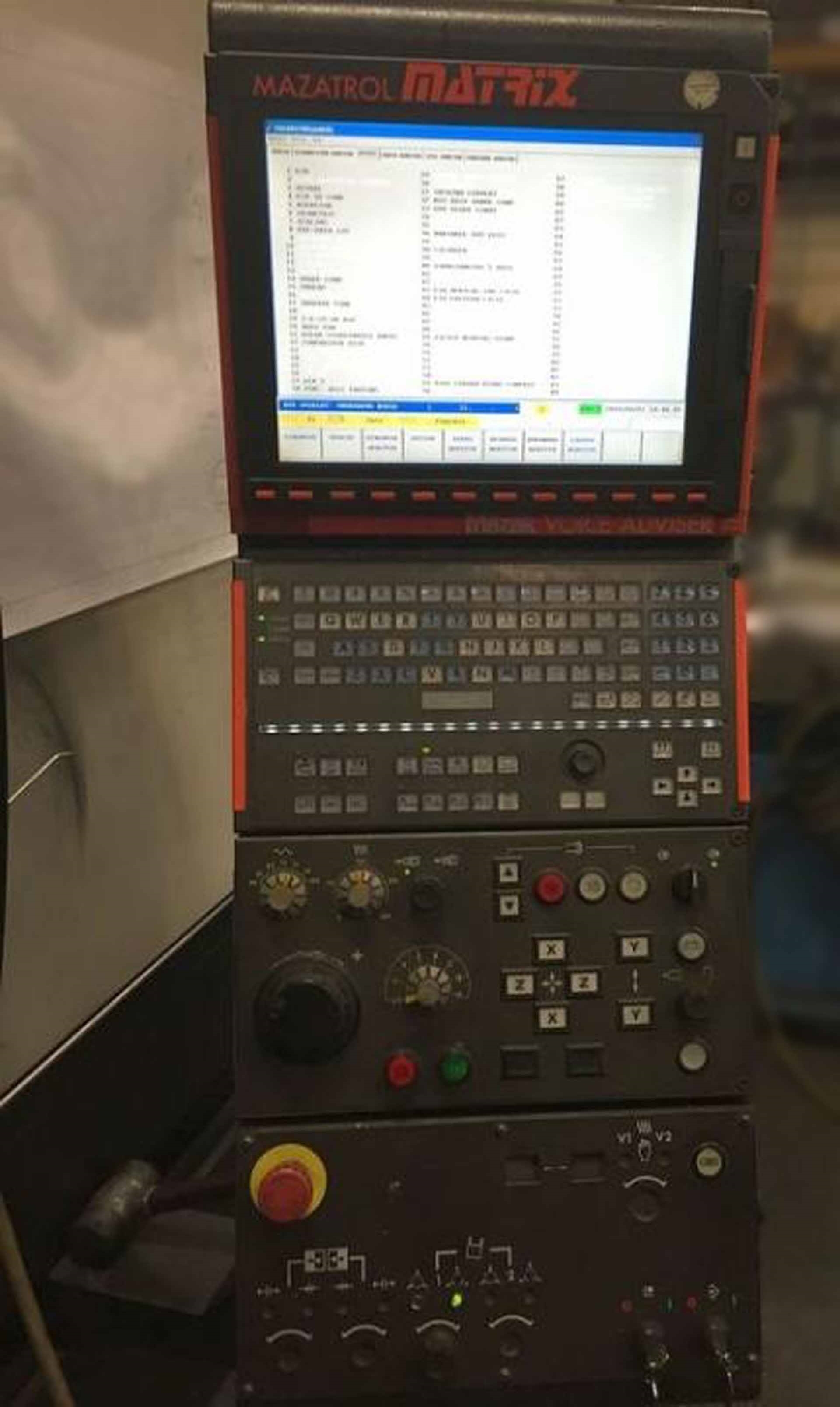

Control: MAZATROL Matrix

Specifications:

5 Axis-simultaneous

Maximum turning length [mm]: 3.060

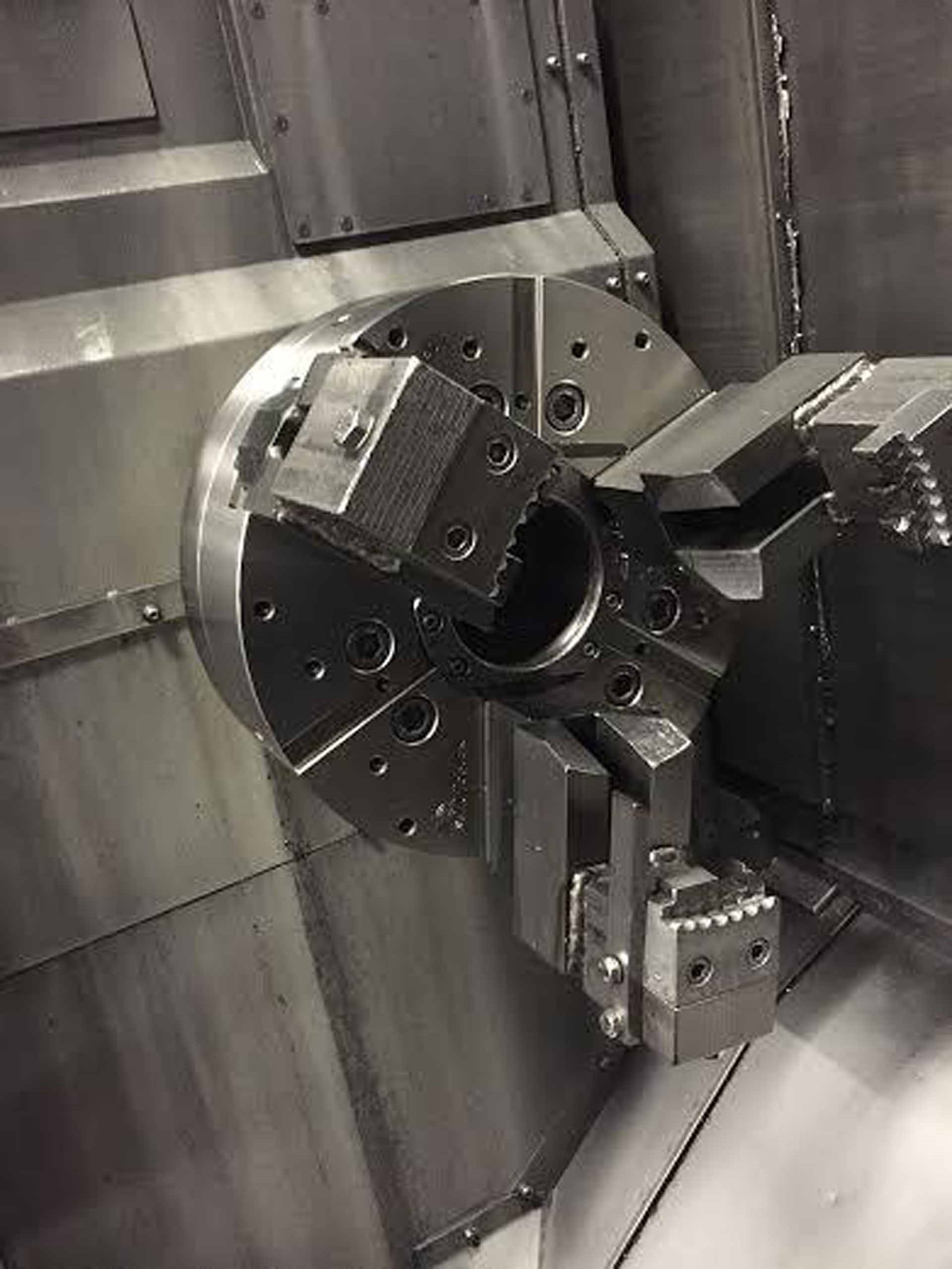

Turning diameter [mm]: 610

Maximum swing over bed [mm]: 610

Maximum swing over slide [mm]: 610

Center height [mm]: 1.250

Spindle bore [mm]: 112

Spindle nose: A2-11

C-Axis: 0,001°

Rotational speed [rpm]: 35 - 3.000

Input power [kW]: 30 / 26

Torque [Nm]: 3.100

Travel:

X-Axis [mm]: 741

Y-Axis [+/- mm]: 410

Z-Axis [mm]: 3.113

W-Axis [mm]: 2.926

Rapid motion (X/Y/Z) [m/min.]: 50 / 50 / 40

Feed (X/Y/Z) [m/min.]: 50 / 50 / 40

Tail stock: MT 5, Programmable

Quill range [mm]: 130

CNC-Spindle tilting for cutting & turning operations:

Rotational speed [rpm]: 15-12.000

Input power [kW]: 22

Torque [Nm]: 326

Tool: Capto C6

B-Axes: 0,0001°

Tool changer:

Tool capacity: 80

Tool diameter [mm]: 95 / 150

Tool length [mm]: 400

Time for tool change [s]: 1,3

Driven tools:

Revolution driven tools: 12.000

E-Tower:

Internal cooling bar

Chip conveyor: MAYFRAN CONSEP 2000 / 70 bar, 3 Stages / 3 steps

Filtration system:

Tool setter

Collets: 410 mm, SMW Autolock

Steady rest: SMW KLU 419, Ø 30-245 mm, Self centering

Interface set:

70 Bar cooling / 70 Bar coolant

MAZAK Monitoring system B optical (RENISHAW MP 700)

Visual tool ID

SMW Bezel / SMW Steady rest

EIA/ISO

Power on time [hr]: ca 50.000

2007 vintage.

MAZAK Integrex e-410H II 3000 is an advanced five-axis multi-tasking machine tool designed to handle many different machining tasks in a single setup. The machine is designed to provide high accuracy, high productivity, and cost-efficiencies for complex parts. Integrex e-410H II 3000 offers three different pallets, allowing users to move workpieces between them quickly and accurately. It also features a rotary table with a maximum speed of 5,000 rpm, which enables users to perform multiple machining operations on a single workpiece in a single setup. The main feature of MAZAK Integrex e-410H II 3000 is its advanced integrated control. The machine integrates both CNC and SFF (Streamlined Functionality Profile) controllers into one unit, allowing for efficient programming and operation. The SFF allows for programming without G-codes, so basic programming skills are not necessary. The machine also features a tool database that allows users to store and retrieve files from the database quickly and easily, eliminating the need to re-enter data each time a task needs to be completed. Integrex e-410H II 3000 also features a powerful spindle drive system, capable of delivering up to 3,000 rpm of torque. The spindle drive system is designed to provide a smooth and consistent drive, reducing chatter and vibration while allowing for greater accuracy in machining operations. MAZAK Integrex e-410H II 3000 also offers an impressive 13-inch color LCD monitor, which provides an intuitive user interface for programming, editing, and operation of the machine. The machine also features a large work area for performing greater tasks and accommodating larger parts. The bed measures 59"x 22" x17" and the maximum turning diameter is 20". Integrex e-410H II 3000 also offers a wide range of features designed to enhance precision and accuracy. The machine includes automatic tool length measuring, tool interference measurement, 3-axis position control, and automatic turret indexing. In addition, the machine is equipped with a spindle pressure monitoring system, which helps to prevent chatter during cutting and ensure that the cutting forces are within the specified range. Overall, MAZAK Integrex e-410H II 3000 is an advanced, reliable, and efficient machine tool, capable of handling many different machining tasks in a single setup. The machine offers high accuracy and cost efficiencies for complex parts, and its integrated control and advanced features provide users with the ability to confidently program and perfom workpieces in a variety of forms and materials.

There are no reviews yet