Used MAZAK INTEGREX e-410HS II #170317 for sale

URL successfully copied!

Tap to zoom

ID: 170317

CNC Lathe system

Control: MAZ-Matrix (e-Tower)

Swing diameter: 610 mm

Working length: 1500 mm

Stroke: 740 x 410 x 1583 mm

B-axis: 240 degree

C-axis: 360 degree

Turning spindle:

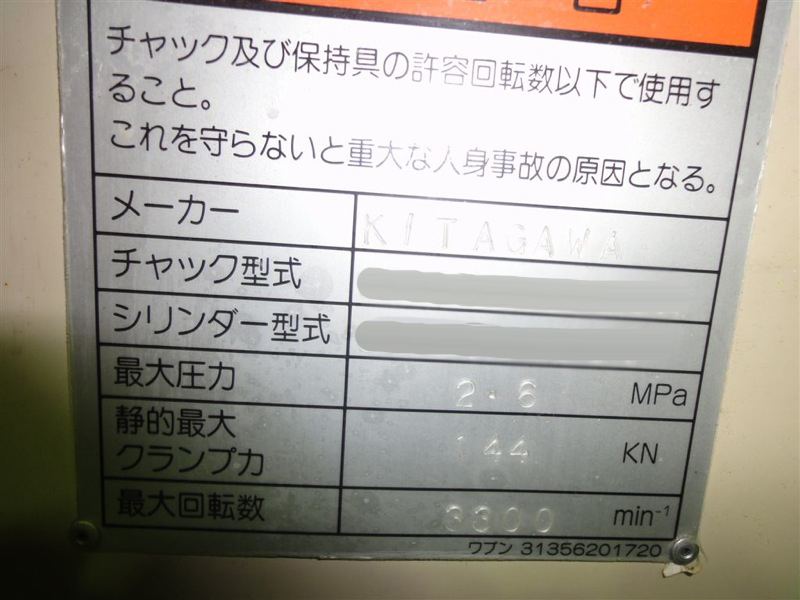

12' chuck (Kitagawa B212A815)

4000 rpm (35 hp)

Through spindle hole diameter: 88 mm

Machining spindle:

BBT-40

Spindle speed: 12000 rpm

ATC-80

Mill spindle coolant

Feedback Scale (X, Y, Z)

Eye Tools

Laser tool measurement mill

Coolant 15K

Coolant temperature control

Oil Skimmer

MMS-B MP700E

e N2 machine tooling specification package

Tapping / Boring Tornado

Stored in a warehouse

2006 vintage.

MAZAK INTEGREX e-410HS II is a high precision, multi-tasking 5-axis, CNC machine tool ideal for a range of industries including aerospace, automotive and energy. This Vertical Machining Center (VMC) provides a highly efficient, high-precision production line able to perform a variety of tasks with ease and speed. The e-410HS II features a 25 HP spindle, with a maximum rpm of 12,000. It also features a cutting volume of 482.6 x 21.6 inches and a maximum workpiece weight of 55,124lbs. It offers high levels of accuracy and repeatability, with X/Y/Z positioning accuracy of 0.0001", 0.0002" respectively. This model is designed with a high level of flexibility, offered through its full 5-axis simultaneous capability. It is capable of handling complex parts requiring contour machining in all axes, even when heavily loaded. With its high machining speed, rigid construction and powerful drives, this model is an ideal choice for high volume production with hard-to-machine components or tight margins of precision. This model also offers extensive tooling options for maximized productivity. With its MDI Controlled Turret and a 66-190 tool capacity, set-up times and operational times are minimized. In addition, the Optional ATC (Automatic Tool Changer) can provide up to 239 tool selection. Integrated Automation Solutions including a generator, tool forestage tables and the use of MAZAK 6-axis and turn-mill robotic cells are some of the many options available for automated manufacturing. Equipped with MAZAK Mazatrol MATRIX® and 4th Generation SmoothG CNC control, this model provides simple and intuitive programming. With features like Digital Tool Sensing Technologies and various conversational programming options, cycle times are reduced and simplified. Additionally, the e-410HS II comes with a variety of standard accessories, including a 60" pallet changer, air conditioning system, cooling system, and chip conveyor, providing a great package solution for heavy machining with sophisticated features. INTEGREX e-410HS II's ability to deliver on dynamic motion and precision is unparalleled and provides an efficient solution for many production needs.

There are no reviews yet