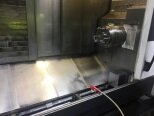

Used MAZAK Integrex e-500 HS-II #9196799 for sale

URL successfully copied!

Tap to zoom

ID: 9196799

Vintage: 2007

CNC Milling / Turning center

Control: Mazatrol matrix

Spindle running time: 7 Hours

Maximum turning length: 3 mm

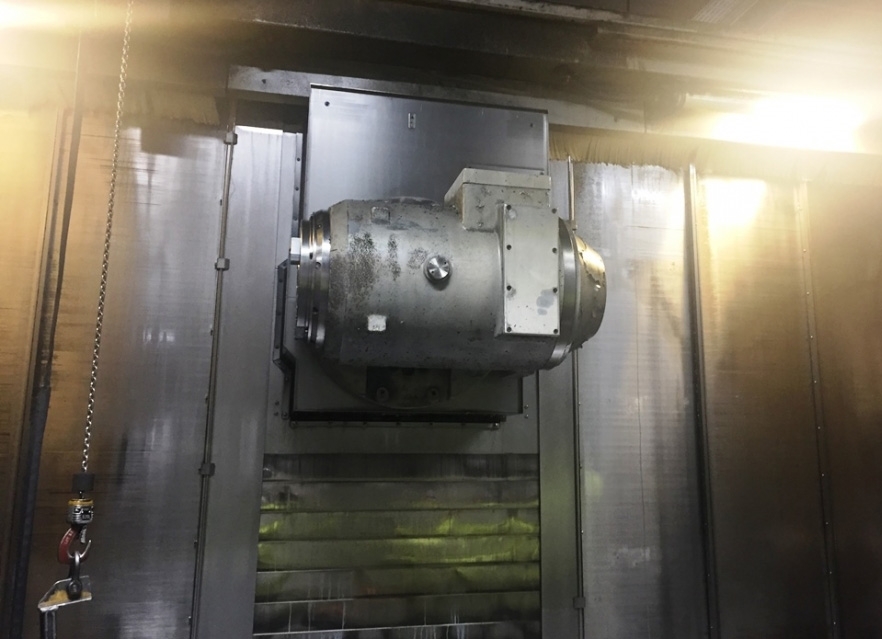

Turning diameter: 820 mm

Maximum swing over bed: 820 mm

Spindle bore: 104 mm

3-Jaw chucks: 610 mm

C-Axis: 0.0001°

Rotational speed: 3.300 Rpm

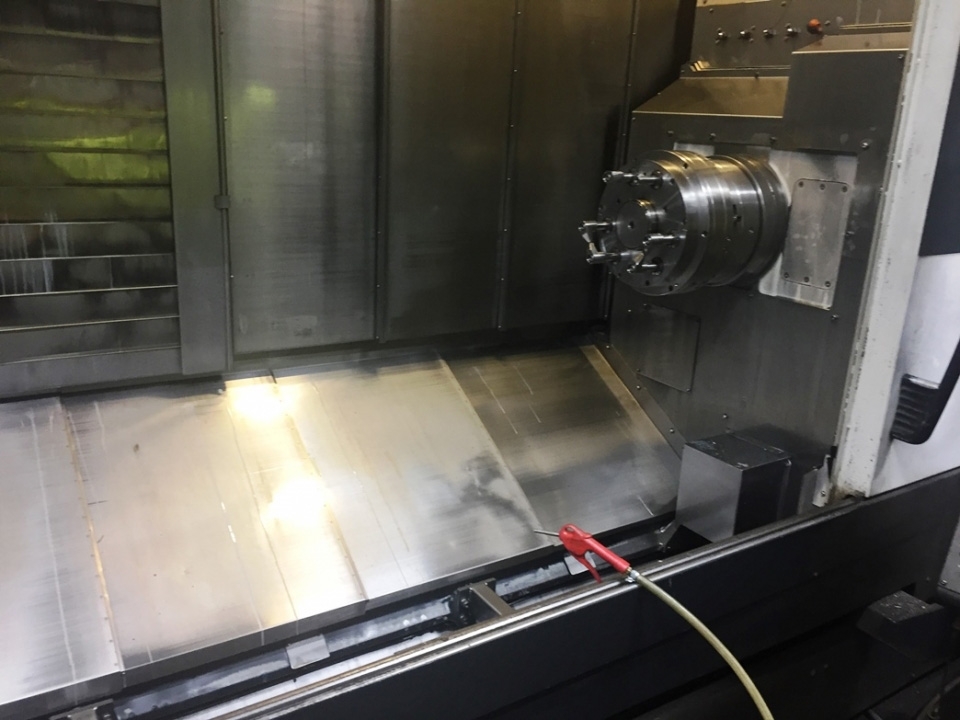

Travel:

X-Axis: 870 mm

Y-Axis: +/- 500 mm

Z-Axis: 3.122 mm

Rapid motion (X/Y/Z): 40 m/min

(5) Controlled axes

Subspindle

Rotational speed: 3.300 Rpm

CNC-Spindle tilting for cutting and turning operations

Rotational speed: 10.000 Rpm

B-Axis: -30° / +210°

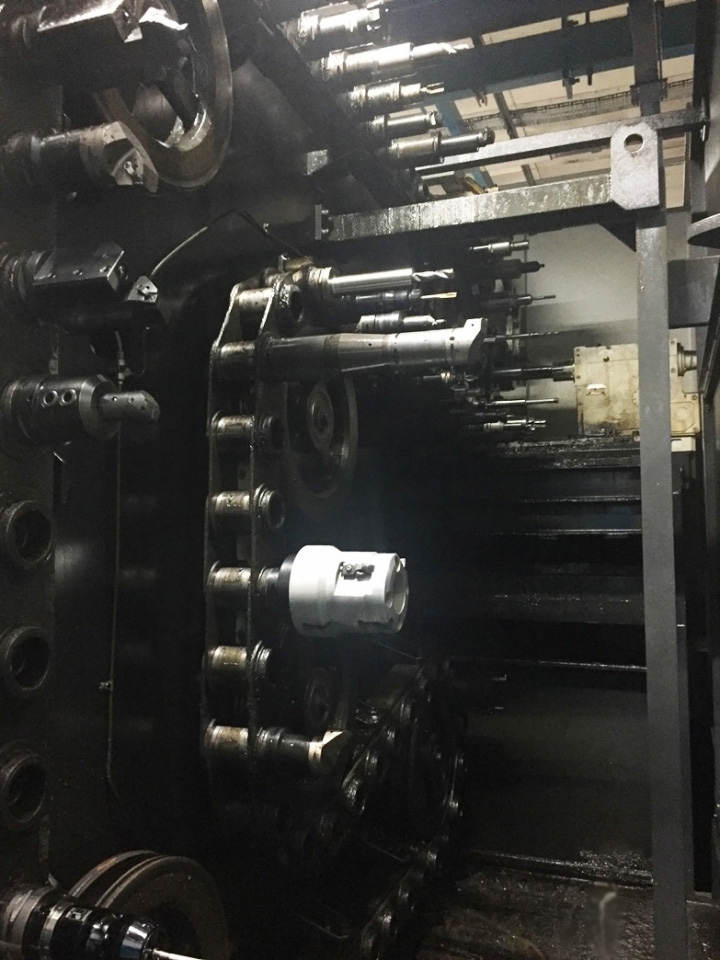

Tool changer:

Tool: Capto

Tool capacity: 80

Equipment:

Chip conveyor: ConSep

Power consumption: 114 kVA kW

Input power: 30 kW

2007 vintage.

MAZAK Integrex e-500 HS-II is an advanced, multi-tasking machine tool designed to deliver cost-efficient solutions for machining complex, multi-faceted parts in a single setup. The machine is built on a cast base, providing rigidity and low vibration for excellent surface finish, higher cutting speeds and improved tool life for repeatable accuracy. Advanced MAZAK manufacturing technology is featured with Integrex e-500 HS-II, such as MAZAK Smooth Technology for improved productivity, MAZAK Smart Tube Manufacturing Technology for high speed tube production and MAZAK TORX Drive for controlled torque and volumetric accuracy. The machine includes a unique B-axis spindle for 3-axis and 5-axis simultaneous machining. It is equipped with a high-performance spindle with speeds of up to 12,000 RPM and a large chuck capacity of up to 242mm (9.53 inches). The spindle is equipped with an integrated C-axis that enables high speed indexing and contouring. Linear motor drives and roller gear cam drives offers smooth and precise motion control while the high-accuracy C-axis spindle allows for indexing and contouring. The ergonomic design of the machine enables easy operator casualness during machine operation. At the machine core is MAZAK advanced control technology. This includes a FANUC 31i intelligent CNC system for rapid and effortless machine setup and operation. Combined with advanced CAM software, MAZAK Integrex e-500 HS-II can achieve accuracy to tolerance of up to 0.005mm (0.0002 inch). It also features MAZAK Advanced Design software, allowing operations to design complex parts in the minimum time frame. In addition to its comprehensive design capabilities, Integrex e-500 HS-II also offers an array of automated loading and unloading solutions. Equipped with an automatic gantry loader, the machine supports multiple loading systems to ensure optimal part flow. MAZAK i-LOADER, for example, allows for multiple modules to be placed inside the machine for fast and efficient part loading. The flexibility of the machine makes it ideal for many applications, ranging from aerospace and moldmaking to medical and automotive. MAZAK Integrex e-500 HS-II offers a powerful and cost-efficient solution for producing complex parts in a single setup.

There are no reviews yet