Used MAZAK Integrex i-200S #9362731 for sale

URL successfully copied!

Tap to zoom

ID: 9362731

Multi-axis CNC turning center

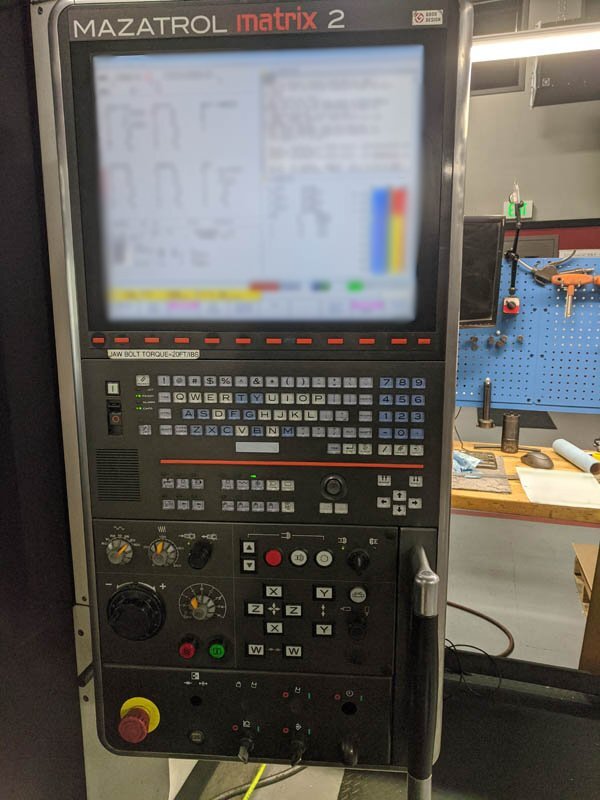

MAZATROL Matrix II Control

Color LCD, 19"

3-D Coordinate conversion

Shape compensation for rotary axes

Milling spindle synchronous tapping

Cardbus I/F: Type II slot

Lan port

USB-I/F

Y-Axis control

Absolute positioning system (Linear axes)

XYZ Pitch error compensation input

Coolant through milling head

Automatic tool eye

Auto chuck jaws open / Close

Coolers for ball screw X-Axis

5-Axis machining package

Relocation device

Chip conveyor side disposal

Work measuring system RMP60 probe

High pressure coolant: 1000 PSI

Air requirement: 71 PSI / 12.7 CFM

Main spindle:

Chuck, 8"

Maximum swing: 25.9"

Maximum cutting diameter: 25.9"

Maximum swing over cross slide: 25.9"

Maximum cutting length: 39.8"

Spindle nose: A2-6

Spindle speed: 35 - 5000 RPM

Spindle index: 0.0001°

Spindle horsepower: 20/30 HP (AC)

Spindle bore: 2.99"

Spindle torque: 344.2 Ft-lbs

Maximum bar work: 2"

Second spindle:

Chuck, 8"

Spindle nose: A2-6

Spindle speed: 35 - 5000 RPM

Spindle index: 0.0001°

Spindle horsepower: 20/25 HP (AC)

Spindle bore: 2.99"

Spindle torque: 240 ft-lbs

Turret and tool:

Type: 1 Position with ATC

72 CAPTO Tool magazine

Tool selection method: Random shortest path

Tool to tool ATC time: 1.3 sec

Maximum tool diameter with pockets full: 3.54"

Maximum tool diameter with pockets empty: 4.92"

Maximum tool length: 15.75"

Maximum tool weight: 26.5 lbs

Rotary tool spindle speed: 15 - 12000 RPM

Rotary tool spindle horsepower: 30 HP (AC)

Rotary tool torque: 88.5 Ft-lbs

Axis travels:

B-Axis: 240°C (-30°C + 210°C, 0.0001°)

Y-Axis: 9.84"

X-Axis: 24.21"

Z-Axis: 42.4"

Second headstock W-Axis: 41.97"

Axis rapid rates:

X and Z-Axis: 1969 IPM

Y-Axis: 1575 IPM

Second headstock W-Axis: 1181 IPM

B-Axis: 40 RPM

C-Axis: 555 RPM

Floor space (WxL): 110.24" x 157.1"

Machine height: 107.1"

Machine weight (36t): 28,880 lbs

213 PSI Thru coolant flood coolant simul-flowable

C-Axis: 0.0001 degree increment (1st Spindle)

2nd Spindle C-Axis with C1-C2 0.0001 degree increments

Chuck air blast 2nd spindle

Rotary tool spindle speed: 12,000 RPM

B-Axis: 0.0001 Deg / Contouring (Requires EIA/ISO)

MT Connect prep

8" Thru-hole chuck B-208A615 1st spindle thru-hole cyl S1552

8" Chuck B-208 2nd spindle with non-thru hole cyl Y-1225

Operating system: Windows 7

Power supply: 62.61 kVA

2013 vintage.

MAZAK Integrex i-200S is a multi-axis machine tool that combines turning, milling, and of vertical machining processes into a single, integrated system. This CNC machine offers high productivity, excellent quality and precision, and simplified production. Integrex i-200S is equipped with a 16" Chuck and automated tool changer consisting of twenty-four (24) tool stations. The machining center has two axes of C-axis rotation on the main and sub spindle for complex indexing. The milling spindle is driven by a 15HP AC motor, while the spindle speed is 3,500 RPM which is ideal for heavy-duty machining. MAZAK Integrex i-200S has a motor driven turret with two independent C-axis rotary tools. The machine is designed to perform a wide range of machining operations such as general turning, drilling, boring, reaming, and threading. It is also equipped with a built-in probing system and advanced software functionality for enhanced automation. Integrex i-200S offers high-precision machining, with an error rate of .0002 inches (0.5 mm) or less. It is also able to achieve cycle times of less than one (1) minute and provide rapid tool changes along with a built-in, fully automated tool changer. MAZAK Integrex i-200S has an enclosed design with an intuitive, easy-to-use control system that is highly reliable. Its control panel features a color touch-screen panel, which provides quick and easy access to operations and functions. It also has an in-built programmable memory that stores up to 200 routines for fast set up and production. Overall, Integrex i-200S provides precise and reliable machining for a wide range of machining operations. It provides high productivity and high-quality machining with its efficient design and rapid tool changing capabilities. The machine is ideal for use in a wide range of markets including aerospace, automotive, plastic, medical, and construction markets.

There are no reviews yet