Used MAZAK Integrex i-400 #9316406 for sale

URL successfully copied!

Tap to zoom

ID: 9316406

Vintage: 2017

Multi-axis CNC turning / Milling center

Maximum swing, 26"

Maximum swing over cross slide: 26"

Maximum cutting diameter: Chucking, 26"

Maximum cutting length: 60"

Total power required (Machine only): 64.66 kVA

Air requirements: 71 PSI / 12.7 CFM

Main spindle:

Spindle nose: A2-8

Spindle bore: 4.41"

Maximum bar work: 4.02"

Spindle speed: 35-3,300 RPM

Spindle index: 0.0001°

36,00,000 Positions

Spindle horsepower (Cont/30 mins.): 40/40 HP (AC)

Spindle torque (30 mins): 1032 ft-lbs

Turret and tooling:

Type of turret: 1 Position, with ATC

Magazine capacity: 36 Tools

Tool selection method: Random shortest path

Tool to tool ATC time: 1.3 sec

Maximum tool diameter with all pockets full: 3.54"

Maximum tool diameter with adjacent pockets empty: 4.92"

Maximum tool length (From gauge-line): 15.75"

ATC Tool shank: CAPTO C6

Rotary tool spindle speed / Ranges: 15-12,000 RPM

Rotary tool spindle horsepower (20% ED) 30 HP (AC)

Rotary tool torque (20% ED): 88.5 ft-lbs

Axis travels:

B-Axis: 240° (0.001° Increments)

Y-Axis: 9.84"

X-Axis: 24.21"

Z-Axis: 62.4"

Axis rapid rates:

X-Axis: 1969 IPM

Y-Axis: 1575 IPM

Z-Axis: 1969 IPM

B-Axis: 40 RPM

C-Axis: 555 RPM

NC Servo tailstock:

Spindle center: MT 5

Maximum thrust: 2244 lbs

Body rapid rate: 315 IPM

Body travel: 61.5"

Equipped with:

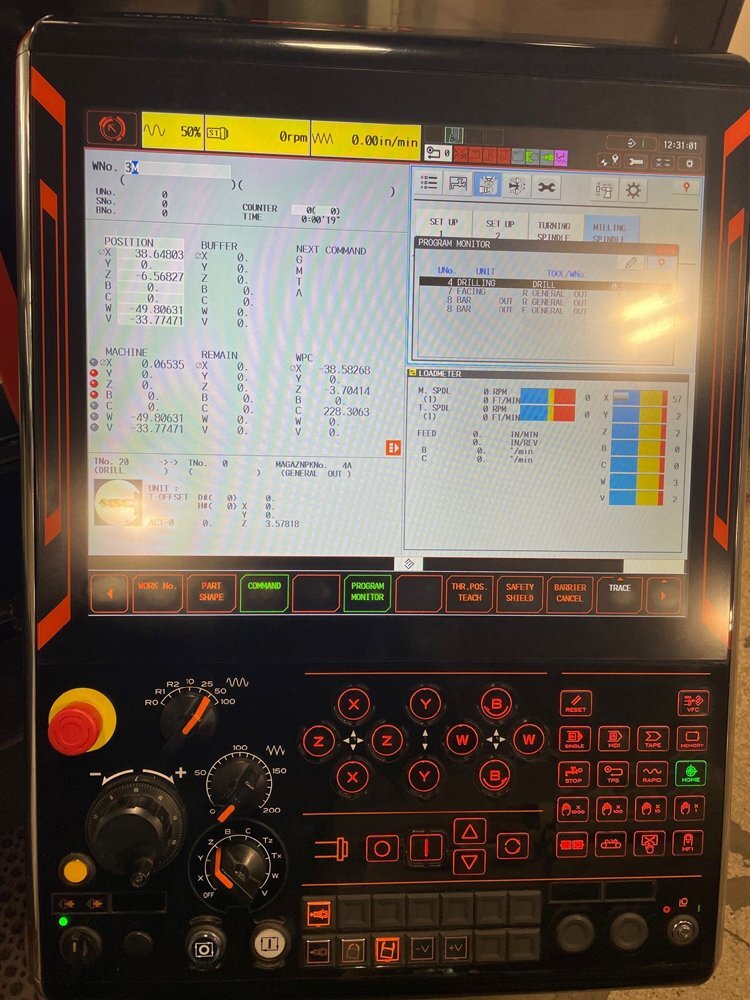

MAZATROL SMoothX Control

Integrex i400w

213 PSI Thru coolant flood simul-flowable

(36) Tool magazines (CAPTO)

Steady rest without bracket (NC Servo Base)

Hinge type chip conveyor side disposal 60” Bed

Smooth engraving function

Re-threading function

5-Axis machining package for SmoothX

Tool radius compensation / 5-Axis

Tool length comp in tool axis direction

Milling spindle synchronous tapping

Y-Axis control

2017 vintage.

MAZAK Integrex i-400 is a multi-functional, advanced and powerful machine tool manufactured by MAZAK Corporation. It is the perfect example of a machine tool with top of the line accuracy, accuracy, speed and versatility. Integrex i-400 is designed to tackle complex 3-D workpieces like medical parts, aerospace components, and fuel injection parts with ease. The i-400 is equipped with two spindles and an able to maintain high levels of accuracy even when switching quickly between them. The spindle first has a maximum speed of 18000 RPM and a second-spindle with a maximum speed of 10000 rpm operating simultaneously. This allows for superior operations with complex workpieces. The powerful spindles enable a high-feed speed of 10,800 mm/min and a rapid traverse rate of 45 m/min for both X and Y axes which enhances the production rate. The i-400 features a highly precise tool measuring equipment that allows for high accuracy and precision. The tool measuring system can measure from 0.25-32 mm diameter for linear and circular tools. The automatic tool changer which is included in the unit has a capacity for up to 180 tools that are able to be automatically changed. The tool-to-tool change time is 1.2 seconds so that production can cycle as quickly as possible. The model also includes a thermal displacement compensation unit, which is used to automatically adjust the tool position to maintain accuracy even when ambient temperatures change. This machine also helps reduce the cutting force build-up, releasing it as the temperature shift occurs. Ultimately, the ability to maintain efficient stability helps lower material stress during production and add to the useful lifespan of the components produced with the machine. MAZAK Integrex i-400 features controlled with state-of-the-art CNC controls, and offers an array of built-in functions such as sub-spindle synchronization, tools interactions and various head-finger movements as well as features unparalleled programming with conversational guidance. Additionally, the CNC controls feature a graphic memory which allow for a possibility of full 3D simulations, helping to correct any potential errors without requiring an operator. Integrex i-400 utilizes an array of advanced technologies for the best production of quality parts. The high-accuracy spindles and the integrated tool measuring tool create products with high precision and accuracy. Additionally, its speedy automatic tool changer and thermal compensation asset, make the machine ideal for high-volume production and long-term components.

There are no reviews yet