Used MAZAK Integrex J 300 #9266080 for sale

URL successfully copied!

Tap to zoom

ID: 9266080

Vintage: 2012

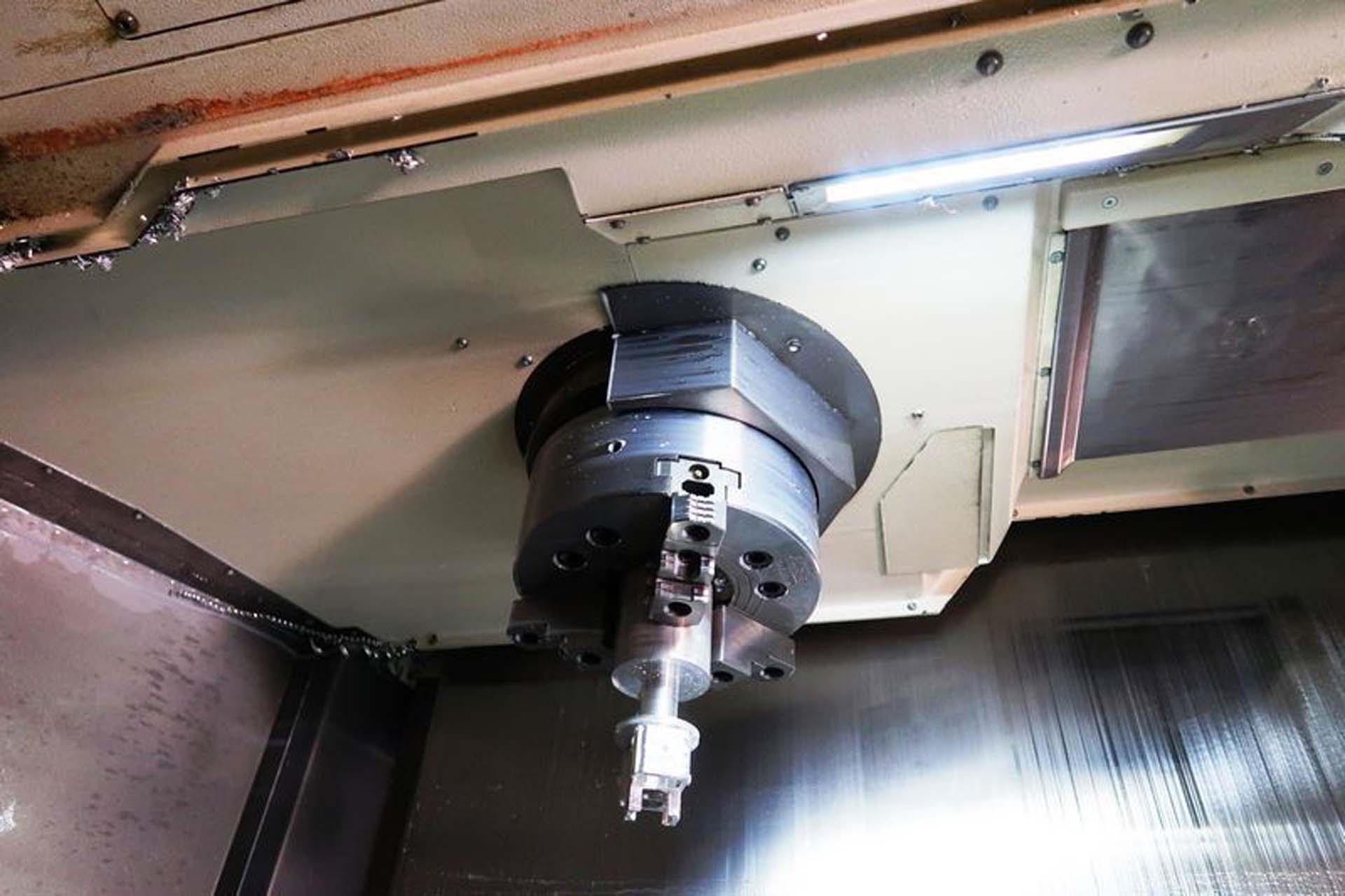

Multi-axis CNC turning / Milling center

Maximum swing, 25.20"

Maximum machining: 19.690" Diameter

Maximum bar work capacity, 3.1"

Maximum machining length, 24.760"

Main chuck size, 10"

Spindle, 25.5"

Maximum speed: 4000 RPM

Motor output: 25 HP

Milling spindle:

B-Axis travel: 220°

Magazine capacity: 20

Maximum speed: 12,000 RPM

Motor output: 30 HP

Feed axis:

Travel X-axis: 24.21"

Travel Y-axis: 10.24"

Travel Z-axis: 27.36"

Travel W-axis: 24.88"

Spindle indexing:

VERSATILE Mill spindle indexing B-axis: 30-190°

High-torque milling spindle

Spindle connections: HSK A63 / CAPTO c6/KM63

Large true Y-axis design

Large tool magazines

Programmable NC tailstock

Coolant thru milling spindle

Chip conveyor

2012 vintage.

MAZAK Integrex J 300 is a 6-axis CNC machining center used for high-precision cutting and advanced machining operations. Its 5-face capability allows for turning, milling, and drilling of complex features simultaneously. The rigid and accurate design of the J 300 ensures stability and reliability, giving customers the most precise and efficient machining technology. The machine features a 30HP spindle motor, capable of delivering up to 6,000rpm for high-end milling and drilling operations. Additionally, the J 300 comes with an advanced 3-axis linear motor equipment, which offers higher velocity and acceleration rates for smoother cutting. This system also provides faster acceleration and deceleration when manually controlling the machine, allowing for more precise machining of intricate parts. The machine's digital 3-axis control unit enables the operator to program and maintain complex cutting paths without the need for manual intervention. MAZAK Control Suite provides a powerful and intuitive user interface that enables programming and editing capabilities in both the conversational and G-code languages. Additionally, customers can take advantage of the advanced data management machine, which can store, sort, and regularly retrieve cutting paths, setups, and other vital machining data. The J 300 comes with a variety of options and features, such as an Automation Tool Changer, an Automatic Pallet Changer, and an optional Robotic Loading Tool. These peripherals help increase the production rate and can free up personnel hours since jobs can run without supervision. The Workpiece Clamping Asset offers easy setup and changing of workpieces for improved accuracy when making complex parts. The durable construction of the J 300 also gives customers added peace of mind. The wide Casting Bed and Corner Columns provide improved thermal stability over other similar models, giving the machine the utmost reliability during extended shift runs. The machine is also effective when it comes to reducing noise, vibration, and operator fatigue. Generally, the machine contributes to a higher level of operator safety while still providing maximum productivity. Integrex J 300 is a high-precision CNC machining center, engineered for producing the most intricate features with maximum speed and accuracy. Its 5-face cutting capabilities, robust linear motor model, advanced digital control, and options such as the Automation Tool Changer and Automatic Pallet Changer make it the ideal machine for any high-volume facility looking to churn out quality parts in a shorter amount of time.

There are no reviews yet