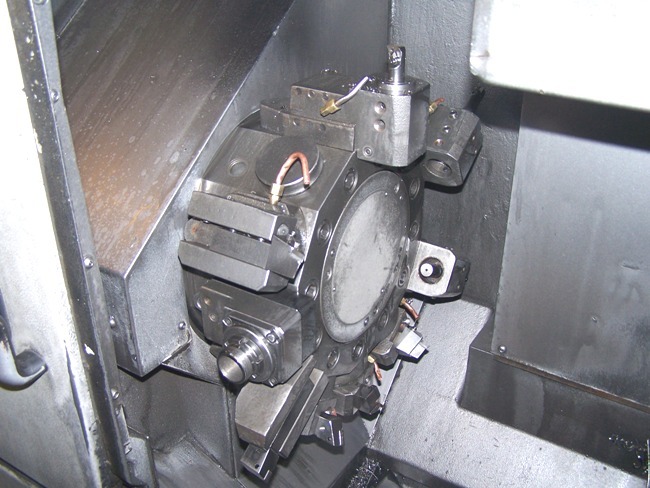

Used MAZAK IVS-200M #9092581 for sale

URL successfully copied!

Tap to zoom

ID: 9092581

Vintage: 2005

Inverted Vertical Spindle CNC machine tools

Chuck Size: 8"

Max Swing Over Bed / Carriage: 11" / 26"

Max Turning Diameter: 7"

Max Machining Length: 4"

Spindle Speed: 7000 RPM

Spindle Nose: A2-6

Spindle Motor: 35 / 30 HP

Tools: 12 (Live)

Rapid Traverse Rates (X / Z): 4330 / 2362 IPM

Milling Motor: 7.5 HP

Milling Speed: 4500 RPM

X -Axis Travel: 12.625"

Z-Axis Travel: 11"

C-Axis Index: .001º

Mazatrol Fusion 640T Nexus CNC Control

Color TFT, 10.4"

Inverted Spindle Lathe

Conversational Programming

3.5" Floppy Disc Drive

Hard Drive: 1.5 GB

PC/MCIA Interface

C-Axis Milling Capability

Hydraulic Chuck, 8"

Coolant Thru Spindle

Spindle Orientation

Mayfran Chip Conveyor (Rear Exit)

Load / Unload Conveyor: Not Included

2005 vitnage.

MAZAK IVS-200M is a machine tool with versatile power and superior manufacturing capabilities. It is designed to provide efficient, accurate and reliable machining of components including turning, drilling, boring, and milling. With its unique intelligent features, including advanced accurate and fast positioning along with eco-friendly low emissions, this machine tool provides the ultimate in precision. The HSR features a 60" working range and allows dynamic cutting with consistent finish, while the 8.7" spindle bore diameter provides efficient operation for finish machining of large workpieces. The spindle motor output of 47hp (at 5,000 rpm) is perfect for deep hole drilling, heavy metal removal, and precise cutting of intricate shapes. Auto-tapping, thread milling and C-axis milling are all included as standard features. An optional Y-axis provides for complex operations, further increasing the machining potential of IVS-200M. The 1000 psi (69 bar) one-touch coolant delivery system with a 1-liter spray nozzle provides for efficient cooling and lubrication. The machines interface is user-friendly with a 10.4 inch color LCD touch screen. The screen allows for storing programs and data for maintenance intervals, alarms, parts counters, and axes settings. An integrated function to support preventive maintenance also ensure the maintenance burden is minimized. The integrated skiving machining with the M1 5C indexer allows for complex tools to be machined and assembled quickly and accurately. Productivity is further increased with multiple sub-spindle configurations, enabling simultaneous machining on multiple parts. For more complex machining, MAZAK IVS-200M also offers multi-tasking where up to eight axes move simultaneously. This ensures a high-speed finish on the most complex components. The open architecture of IVS-200M facilitates communication with various production and network systems, allowing for easy integration into connected factories. Plus, with its low noise operation and top-notch heat dissipation system, this machine offers a healthy working environment. MAZAK IVS-200M Machine Tool is perfect for anyone looking to tackle challenging projects, increase productivity, and reduce costs. With its powerful spindle, unmatched accuracy, and exceptional advanced features, IVS-200M is guaranteed to bring your company to the next level of production.

There are no reviews yet