Used MAZAK Nexus VCM-510C #9044646 for sale

URL successfully copied!

Tap to zoom

ID: 9044646

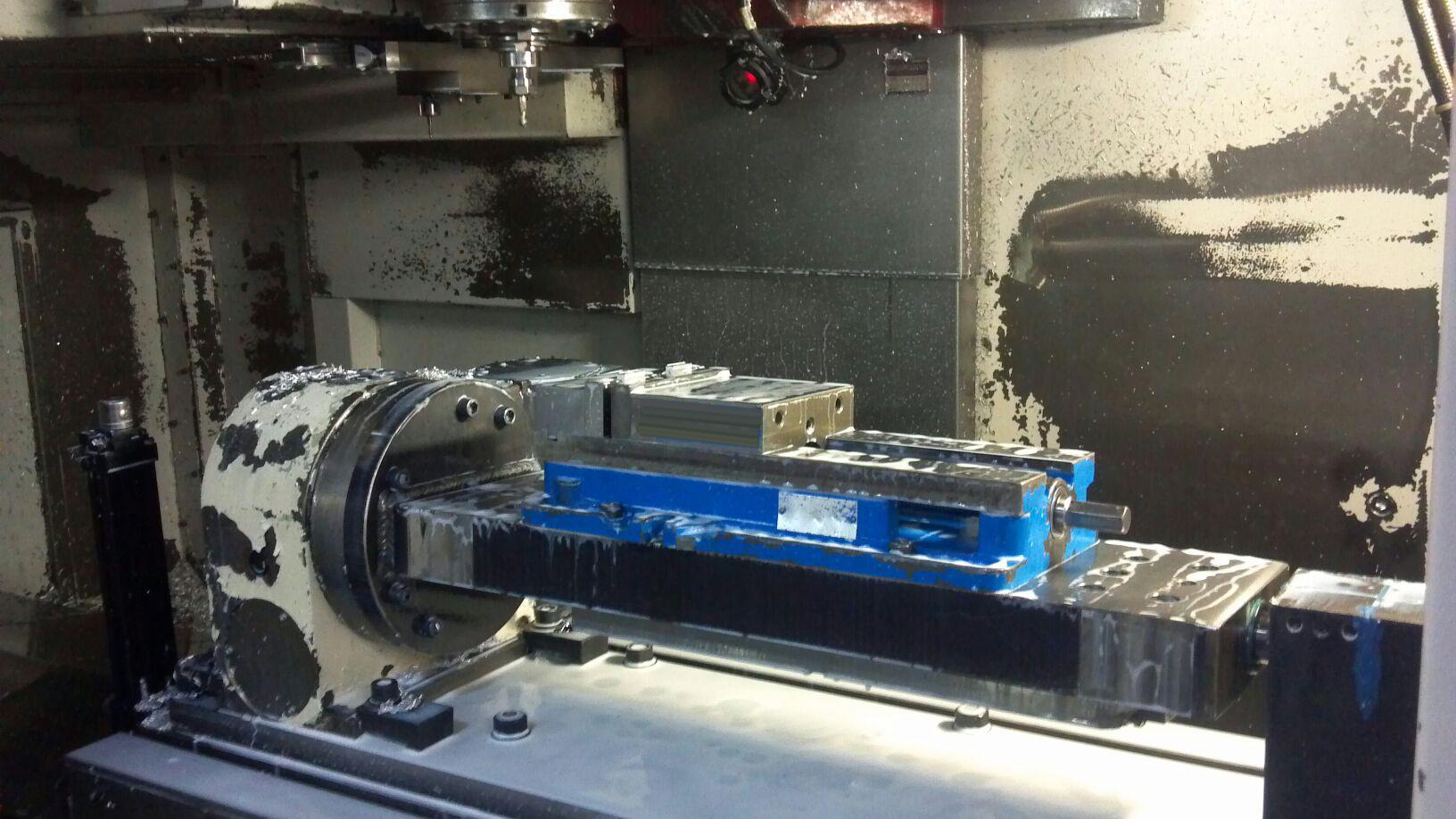

Vertical Machining Center

Includes:

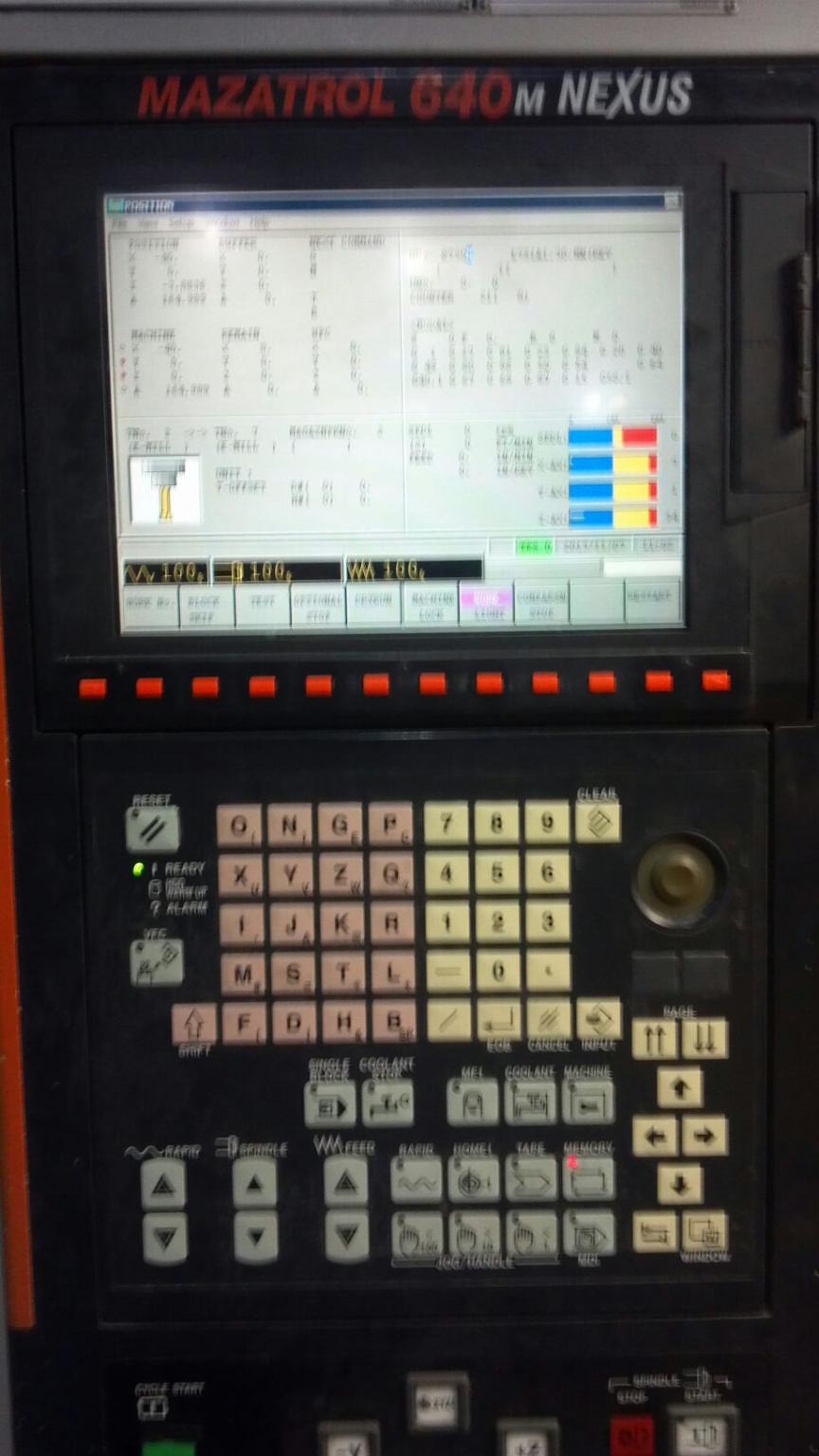

Mazatrol 640M Nexus CNC Controls

4th-Axis Ready

48-Position Automatic Tool Changer

High Pressure Flood Coolant

Chip Conveyor

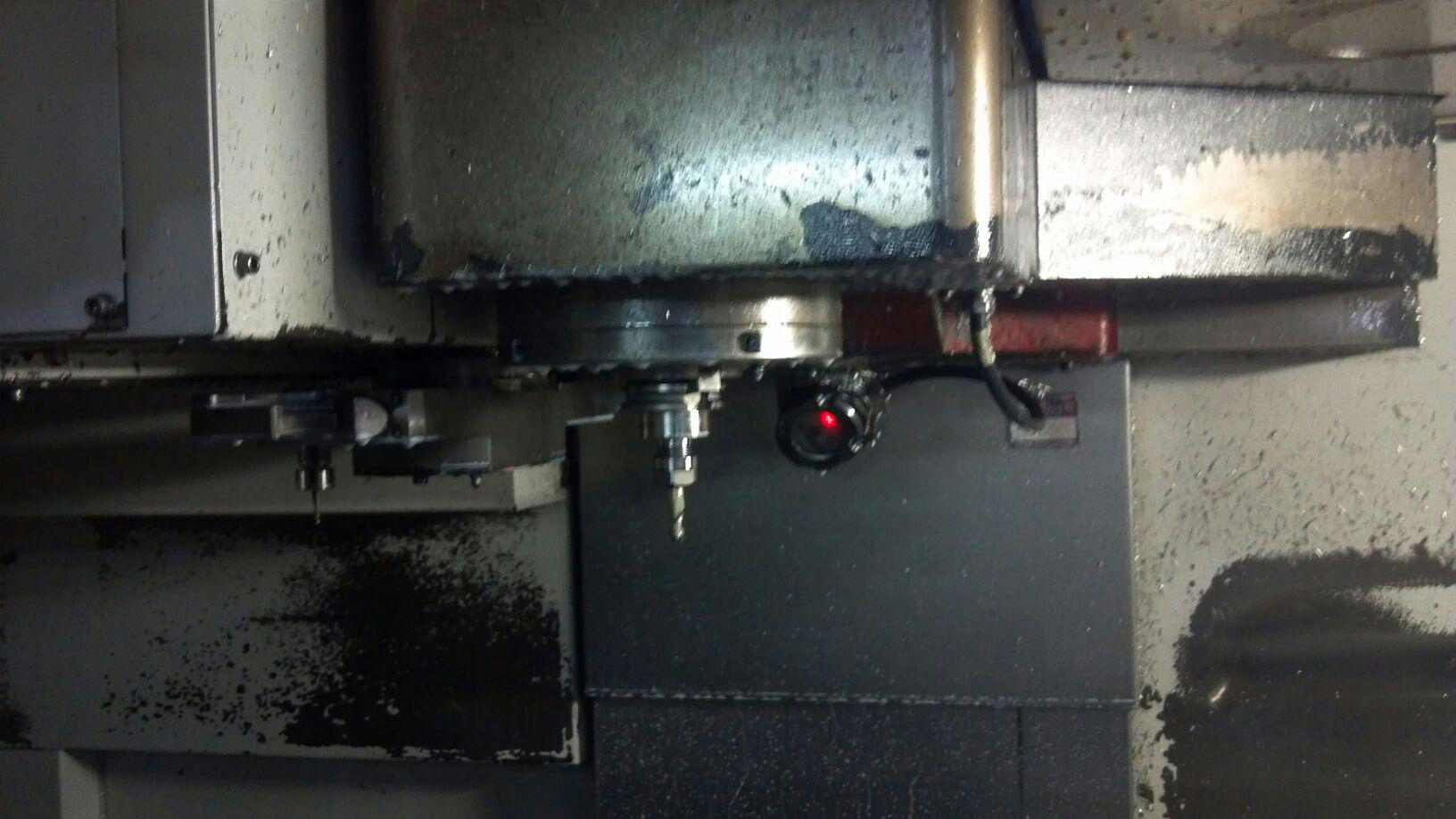

Renishaw Optical Probes

Mazatrol Champion Package

PCMCIA Slot

Factory-Installed NC4 Laser Probe

Cyber Monitor Software

Coolant through the Spindle

Specifications:

Table size: 21.65" x 51.18"

Maximum table load: 2,640 lbs.

Travels:

X-Axis: 41.34"

Y-Axis: 20.08"

Z-Axis: 20.08"

Distance spindle nose to table top: 5.9" - 25.98"

Cutting feed rate: 0.03" - 1417" / min.

Rapid traverse rate (all axes): 1417" / min.

Spindle speeds: Up to 12,000 RPM

Spindle taper: CAT 40

Spindle motor: 25 HP 3 / 60

2005 vintage.

MAZAK Nexus VCM-510C is a vertical machining center (VMC) designed for efficient and precise cutting of materials, resulting in high-quality parts and components. This 5-axis CNC machine tool is durable, easy to operate and allows for increased productivity from one cycle to the next. The VCM-510C has an operating range of 510 mm (X-axis) by 510 mm in (Y-axis) by 457.2 mm (Z-axis) and also features a Pallet Changer with two pallets, allowing for increased workpiece capacity. The VCM-510C is able to perform a number of different operations, including milling, drilling, tapping, boring, reaming, and contouring. The use of different tool diameters is possible, and tools can be changed automatically, which ensures that each operation receives accurate attention. The machine is powered by the Mazatrol Matrix control system, which is a copy of the World Famous Mazatrol programming language. This gives the user the benefit of being able to enter commands in the form of a program and giving the machine the required instructions. It also allows for the operator's programming code to be shared between various machines, reducing errors and eliminating delays and material wastage. The VCM-510C is built on a rigid and stable construction using castings that are mounted onto the base table. These castings are heavily ribbed, and are bolted tightly together to reduce vibration and noise. This structure ensures durability and high accuracy throughout its lifetime. The VCM-510C is equipped with three high precision linear scales, and one glass scales for the B-axis, which measures angular movement. This is also enhanced with a Heidenhain encoder which is positioned between the spindle and the main bearing, allowing precise accuracy for cutting operations. This CNC machine is also equipped with a high precision torque motor and a spindle cooling system. The torque motor enables smooth acceleration and deceleration, which helps the machine achieve high accuracy and precision especially when used along with the machine's high-speed automatic tool changer. The spindle cooling system ensures maximum spindle life and reduces thermal deformation of the spindle structure. Overall Nexus VCM-510C is an advanced, efficient and reliable machine tool. It is user-friendly and can handle complex and precise cutting operations with little to no manual intervention. Versatility is increased as programs can be transferred to other machines, reducing errors and providing a cost-effective production strategy. With its Heidenhain encoder and high-precision linear scales, the VCM-510C can ensure quality parts and components, free of errors and with a high level of accuracy and repeatability.

There are no reviews yet