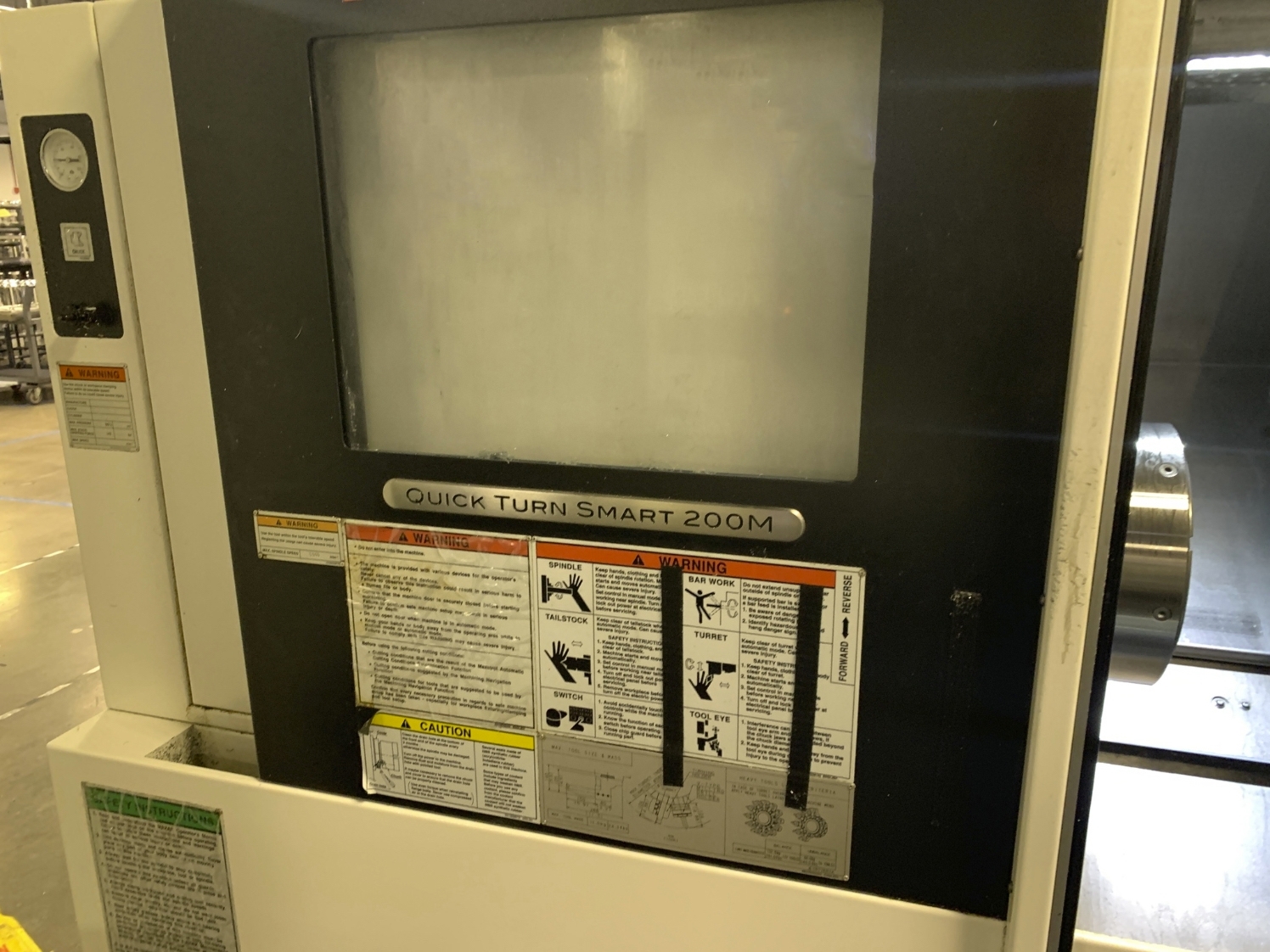

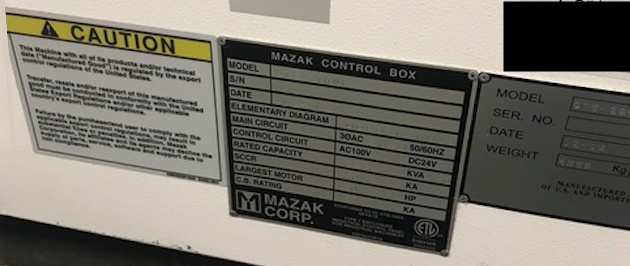

Used MAZAK Quick Turn 200M #9266480 for sale

URL successfully copied!

Tap to zoom

ID: 9266480

CNC Turning machine

Characteristics:

Powerful main turning spindle

Rotary tool milling spindle

CNC Programmable tail stock

Through hole chuck packages

Automatic tool eye

Easy integration of bar feeders and gantry robots

Specifications:

Maximum swing: 25.98"

Standard machining diameter: 9.25"

Maximum machining diameter: 14.25"

Maximum bar work capacity: 2"

Maximum machining length (20" / 40" bed): 21.03" / 41.53"

Chuck size: 8"

Maximum speed: 5000 RPM

Spindle nose: A2-6

Spindle through hole diameter: 2.99"

Spindle torque (Max): 264 FT / LBS

Milling spindle 40% ED: 4,500 RPM / 7.5 HP

Travel X axis: 8.87"

Travel Z axis (20"/ 40" bed): 23.75" / 44.25"

Turning tool size (outside / inside): 1" / 1.5"

Indexing time (one / full): 0.23 sec / 0.62 sec

Rapid traverse (X/Z): 1,181 / 1,299 IPM

Motor output (30 minute rating): 25/20 HP / 26 kW

Number of tools: 12

Maximum speed: 6000 RPM

Motor output (10 minute rating): 10 HP / 8 kW

Travel (W Axis): 22"

No tail stock.

MAZAK Quick Turn 200M is a CNC (Computer Numerically Controlled) lathe machine tool designed for high speed machining tasks. It is capable of high production levels with reduced production costs. This equipment was developed by Japanese company MAZAK Corporation and it is one of the most advanced and durable CNC lathes available. Quick Turn 200M has an advanced Y-Axis machining design that allows the machine to perform multiple controlled movements on all four axes. It's large-diameter spindle will rotate its cutting tools up to 4000 rpm in continuous or adaptive variable speed values, providing improved productivity and accuracy. The spindle head, which is supported by two heavy-duty bearings, features an automatic tool changer with a tool magazine that can carry up to 400 tools. The machine's CNC control is equipped with a large 15-inch LCD touchscreen panel with an intuitive graphical interface. MAZAK Quick Turn 200M has an ATC (Auto Tool Change) system which can handle tool changes with minimal downtime. Its powerful Fanuc CNC system is designed to provide superior accuracy, repeatability and process control. The interactive graphical programming software allows programming directly on the machine or on the optional PC unit. Quick Turn 200M has a robust construction and offers exceptional stability for accurate and precise machining. It is equipped with an independent servo drive feed system that allows it to achieve freeform contouring with high feed rate. The feed rate can be as high as 37 m/min in rapid traverse mode, and in addition, the machine features a built-in backlash compensation for improved machining accuracy. The machine also features a power driven tailstock with a tooling turret that moves axially for stable part mounting and makes part handling easier. It is equipped with a C- Axis indexing function which provides turning, drilling and tapping operations. Overall, MAZAK Quick Turn 200M is a high-speed and robust CNC lathe machine that is perfect for manufacturing complex parts with high precision. Its sophisticated features make it suitable for many high production applications. It is capable of providing reliable operation at low operating costs.

There are no reviews yet