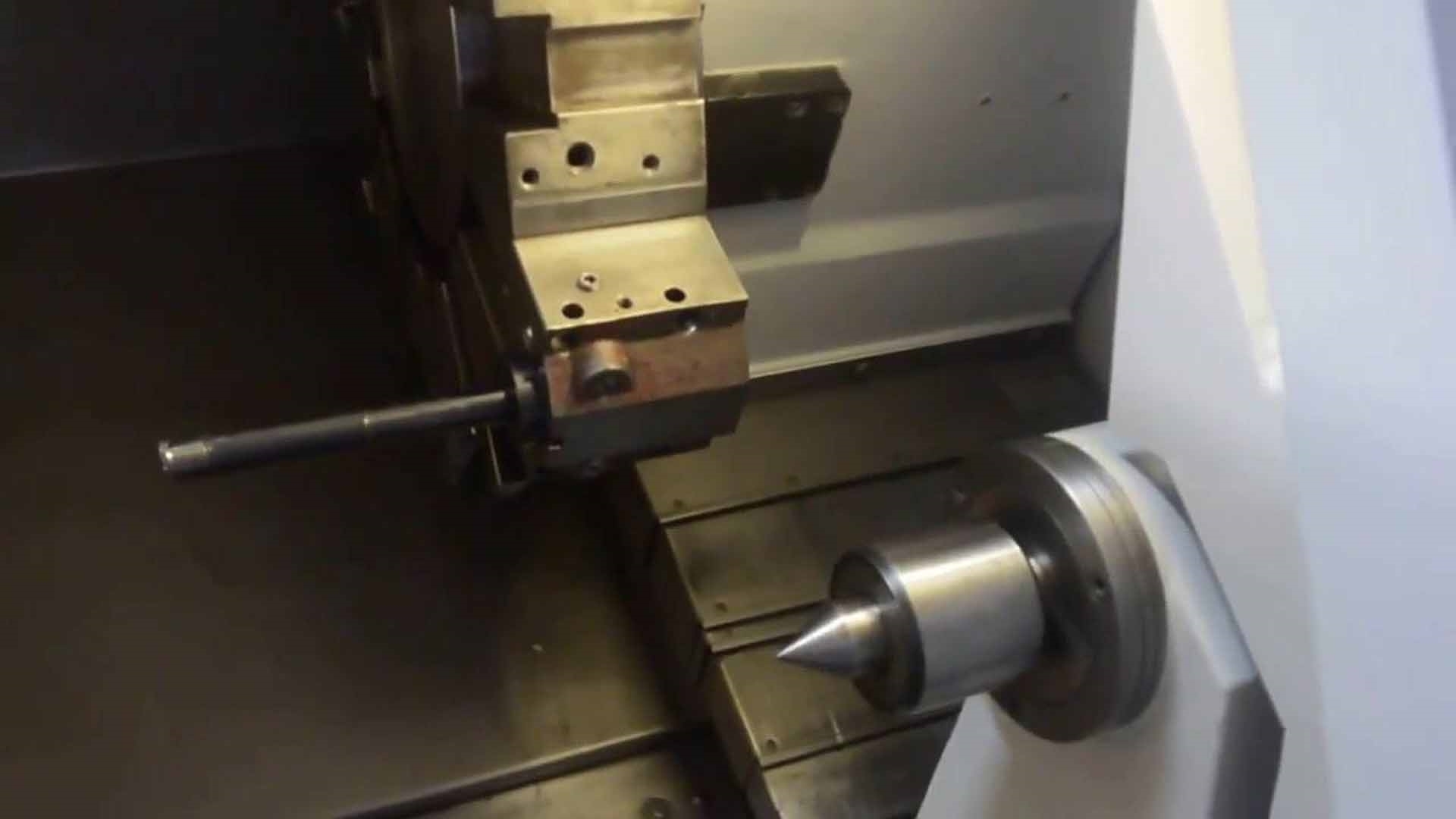

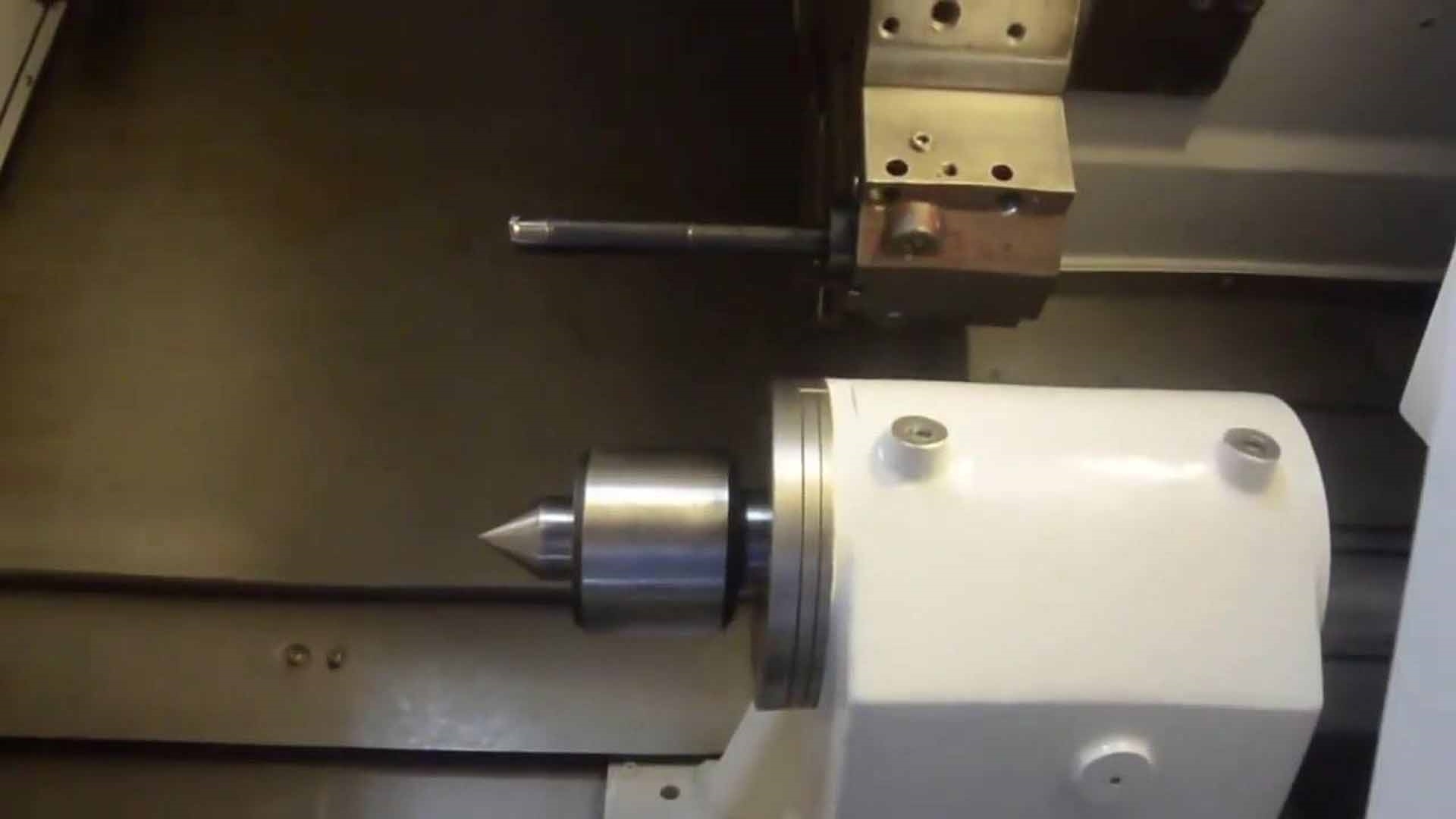

Used MAZAK Quick Turn Nexus 250-II #9229884 for sale

URL successfully copied!

Tap to zoom

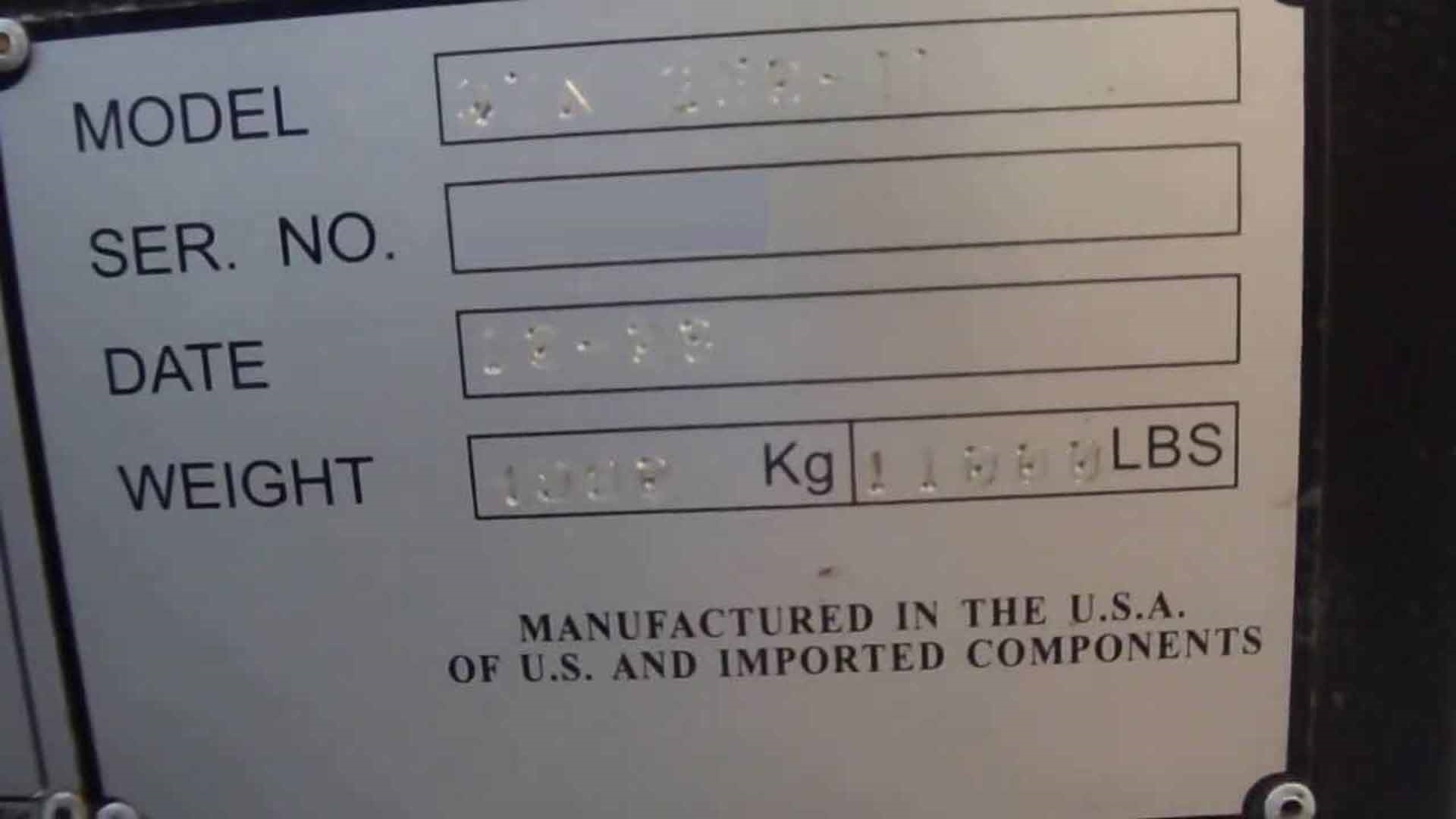

ID: 9229884

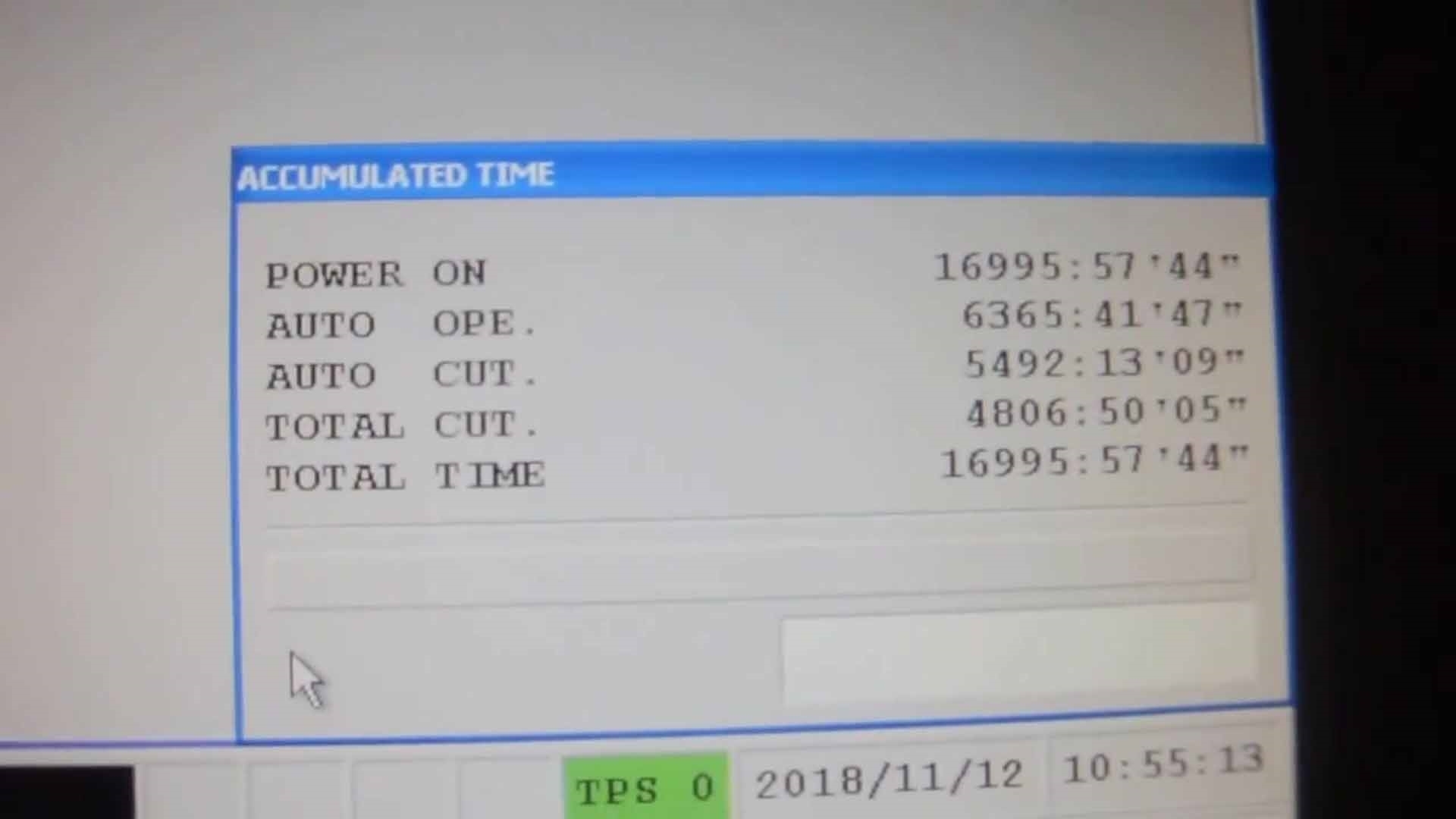

Vintage: 2008

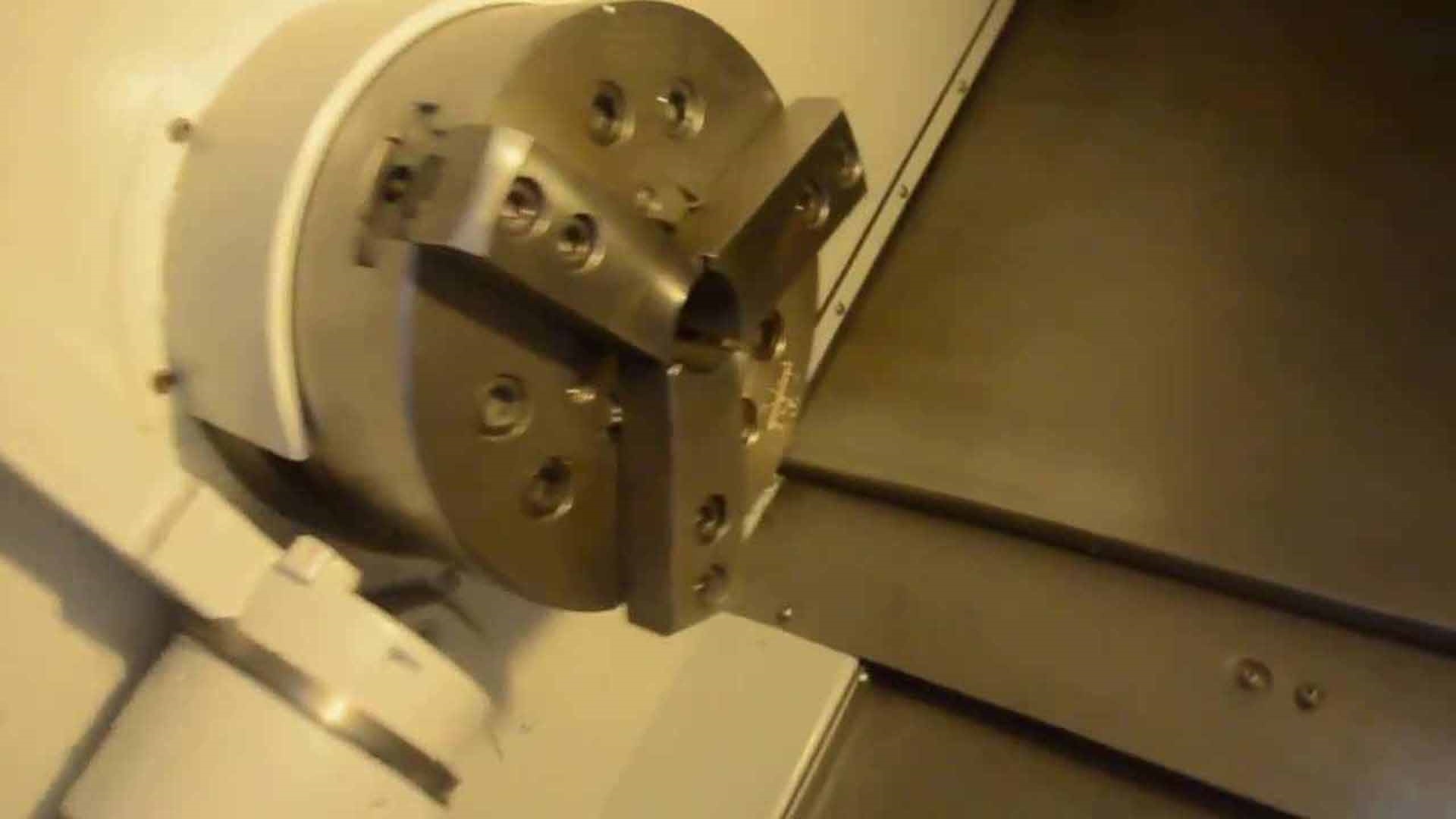

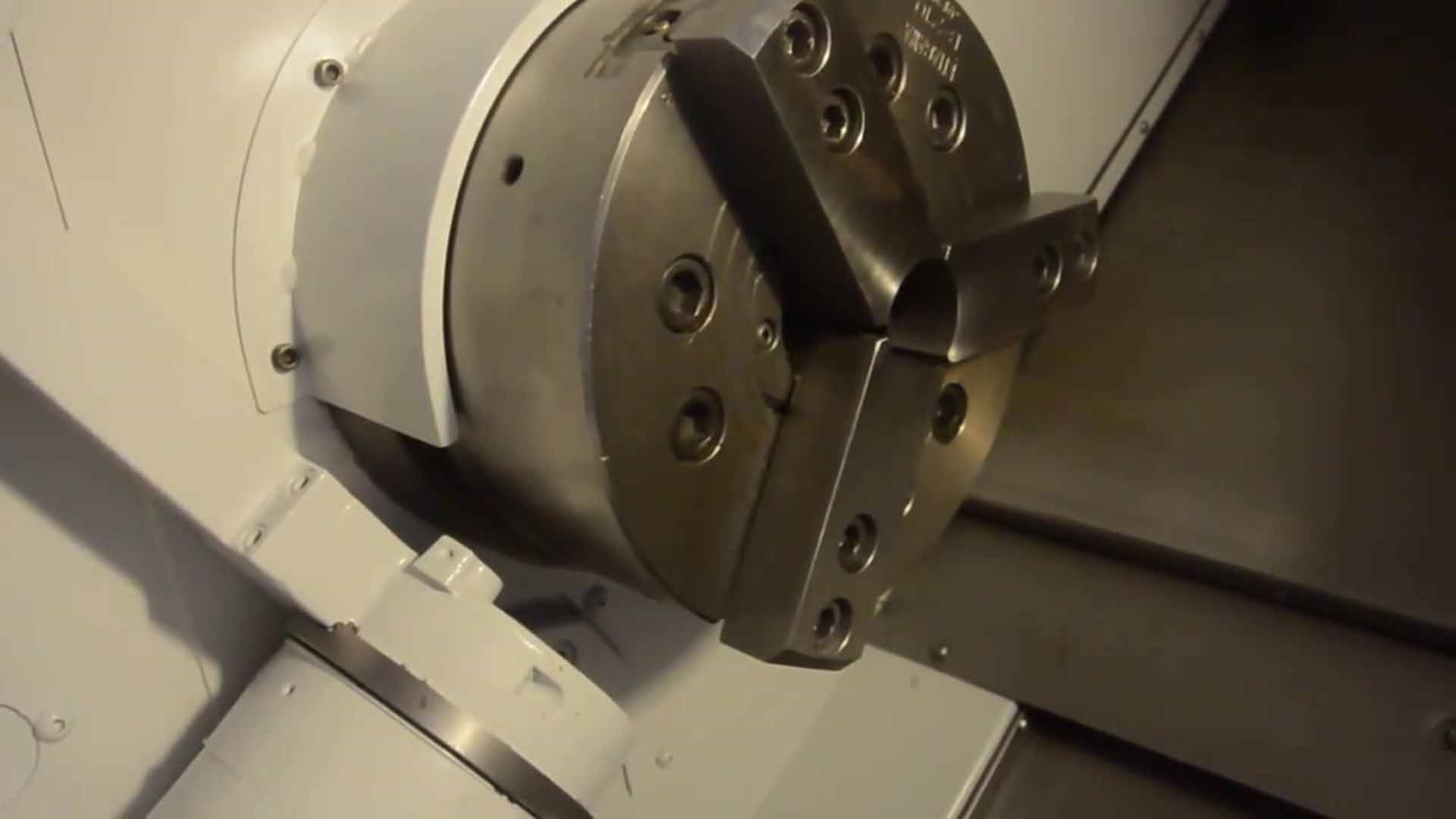

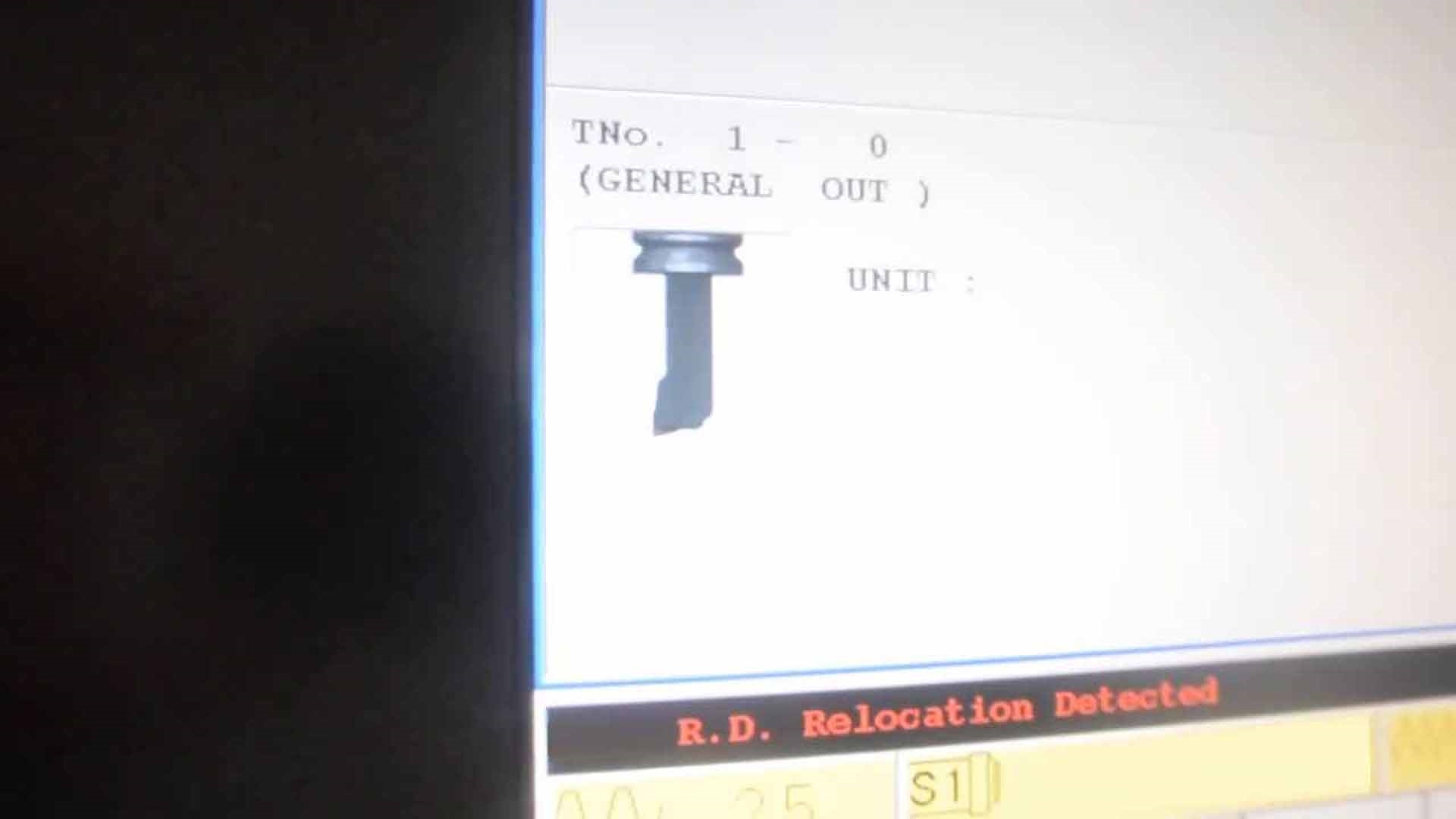

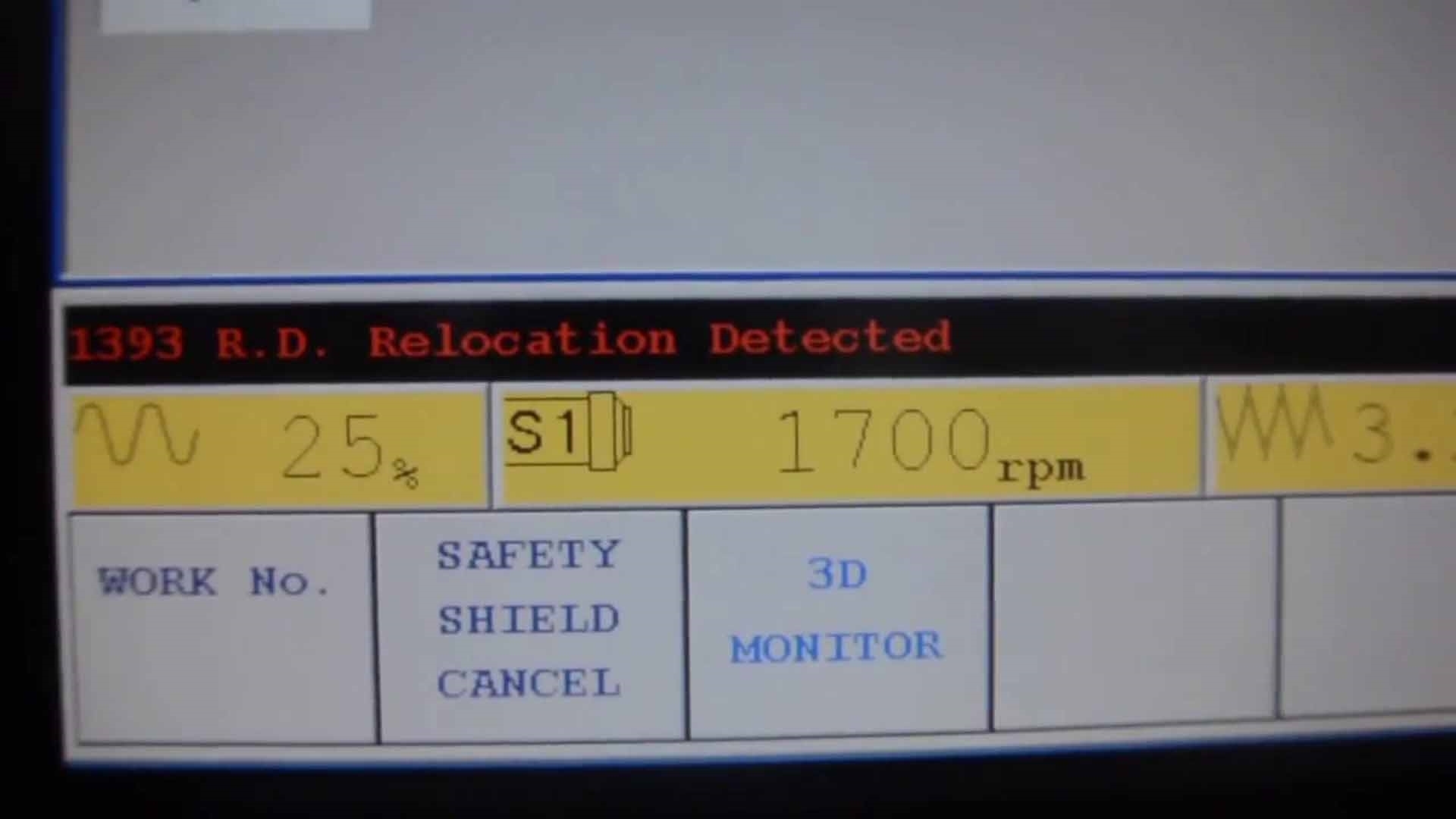

CNC Turning machine

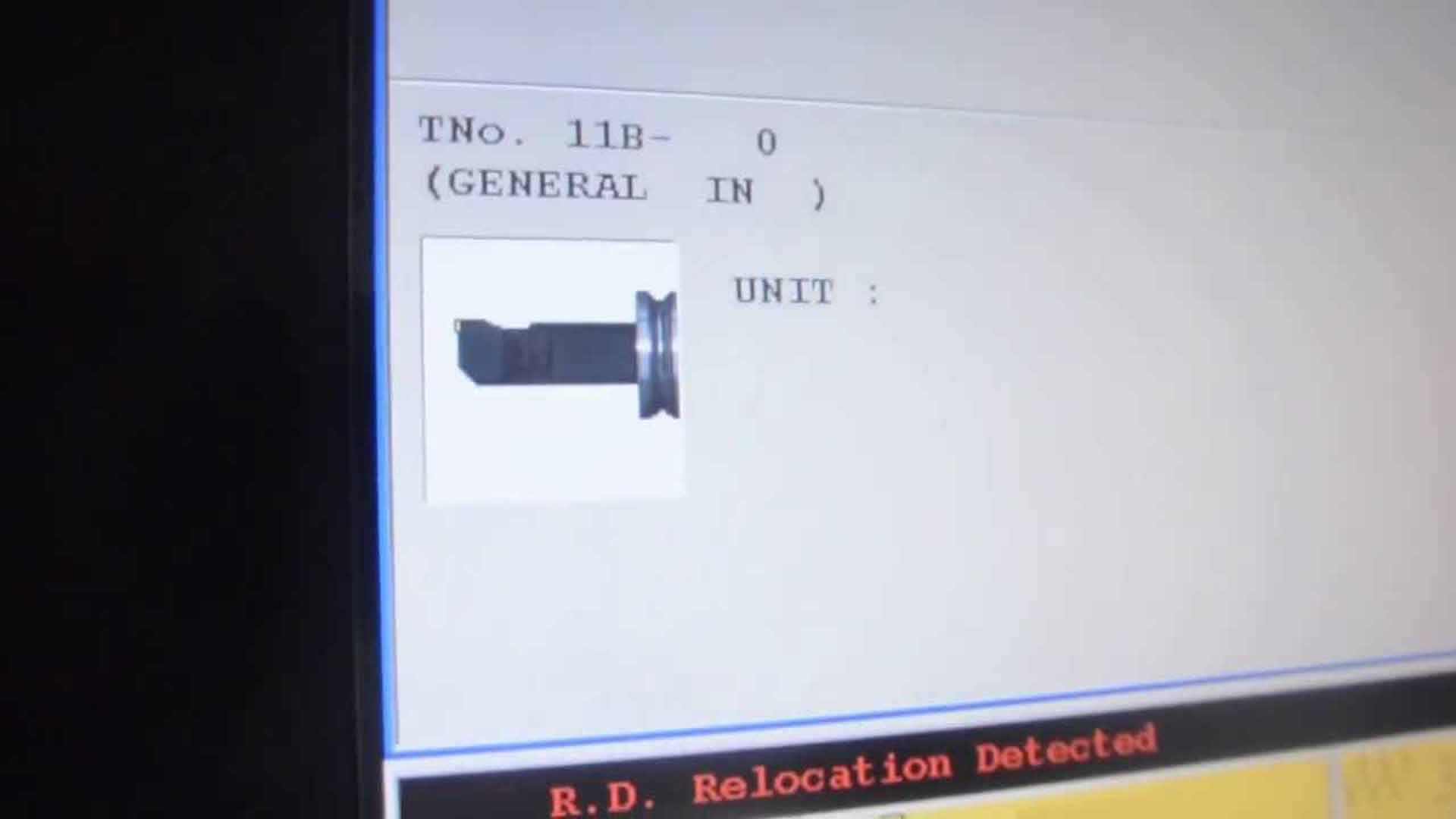

MAZATROL Matrix CNC controller

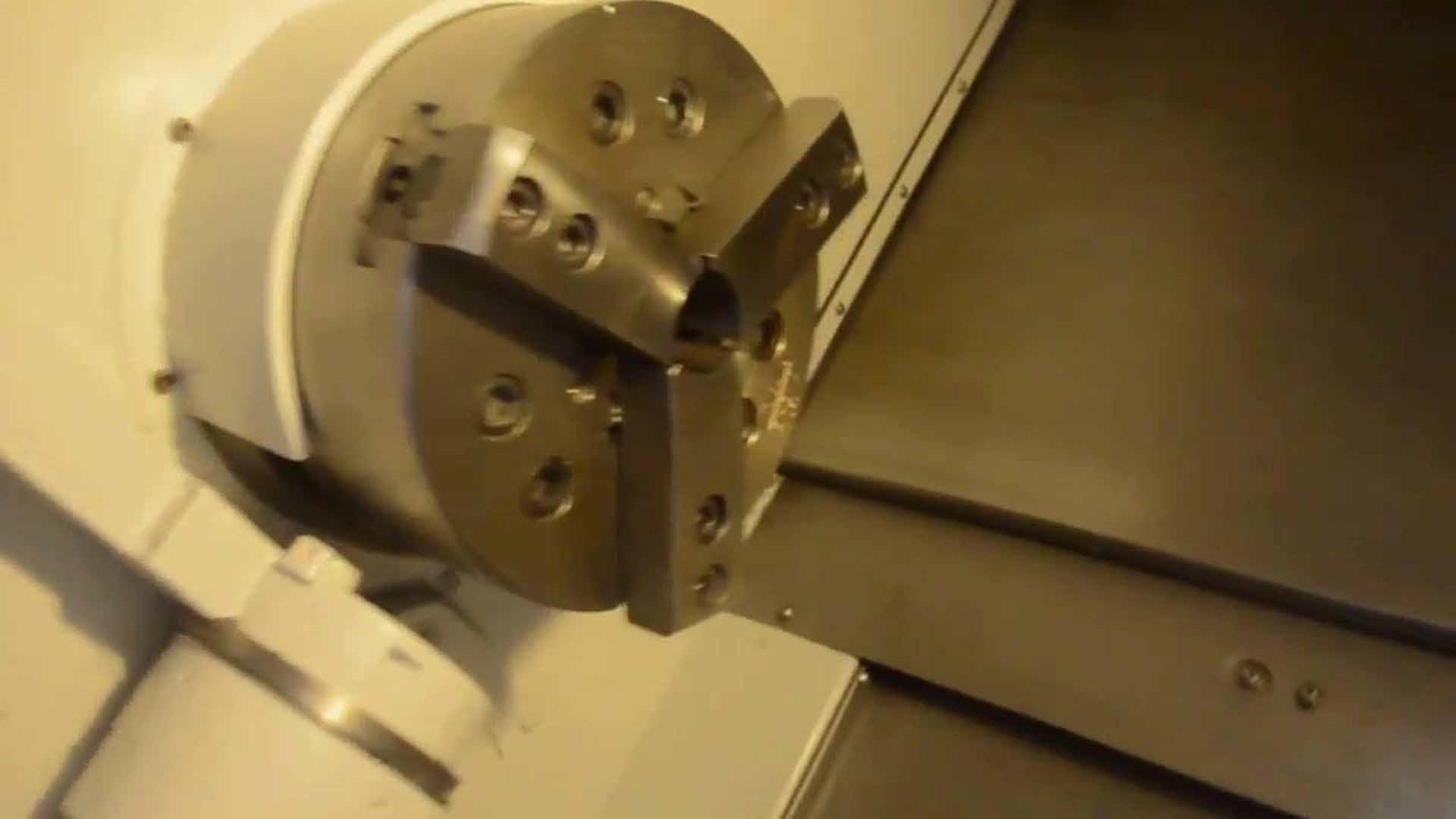

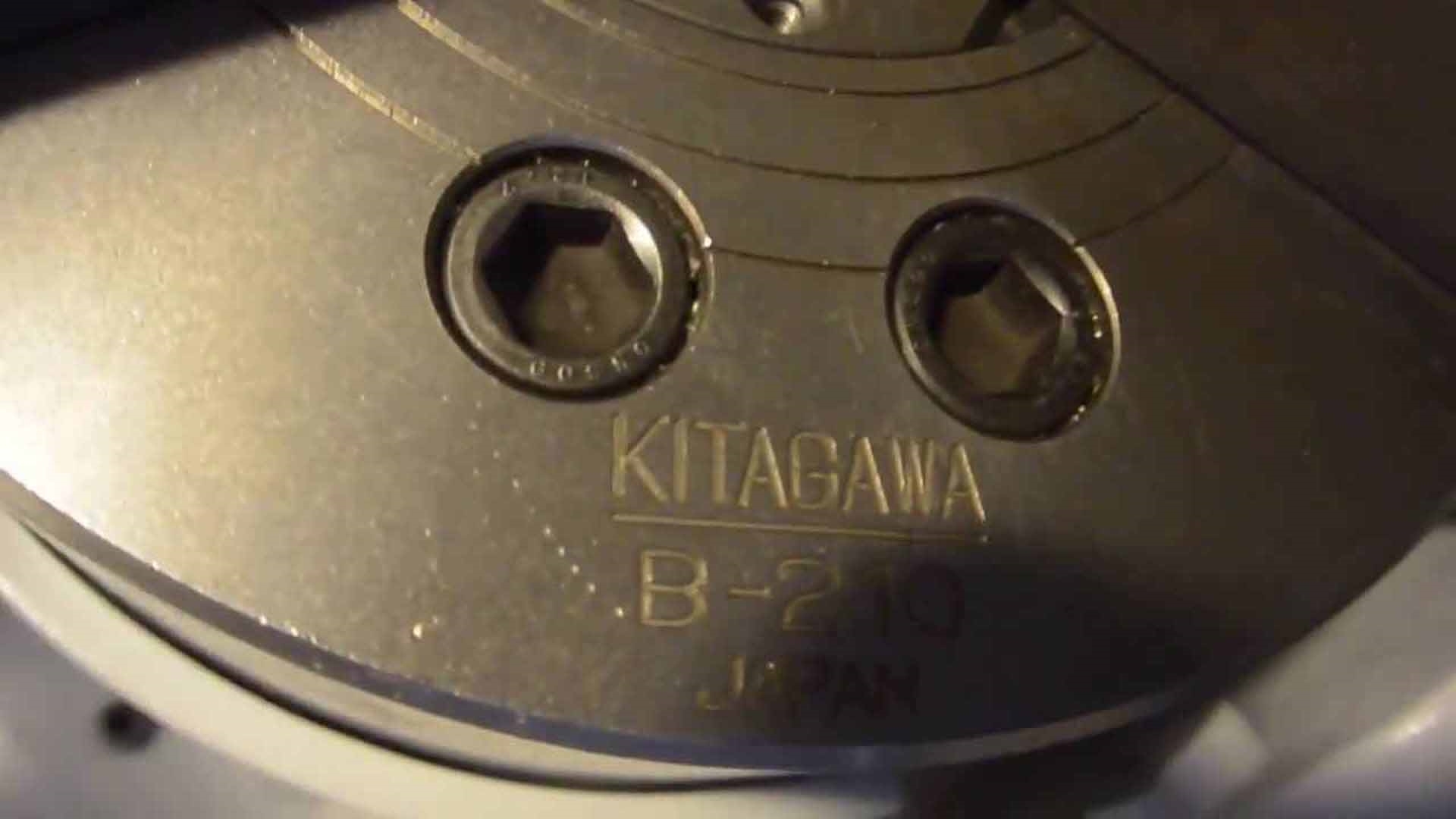

KITAGAWA Hydraulic chuck, 10"

Maximum swing: 24"

Turning diameter: 14.75"

Turning length: 21.7"

Spindle bore, 3.15"

Spindle speed: 4000 RPM

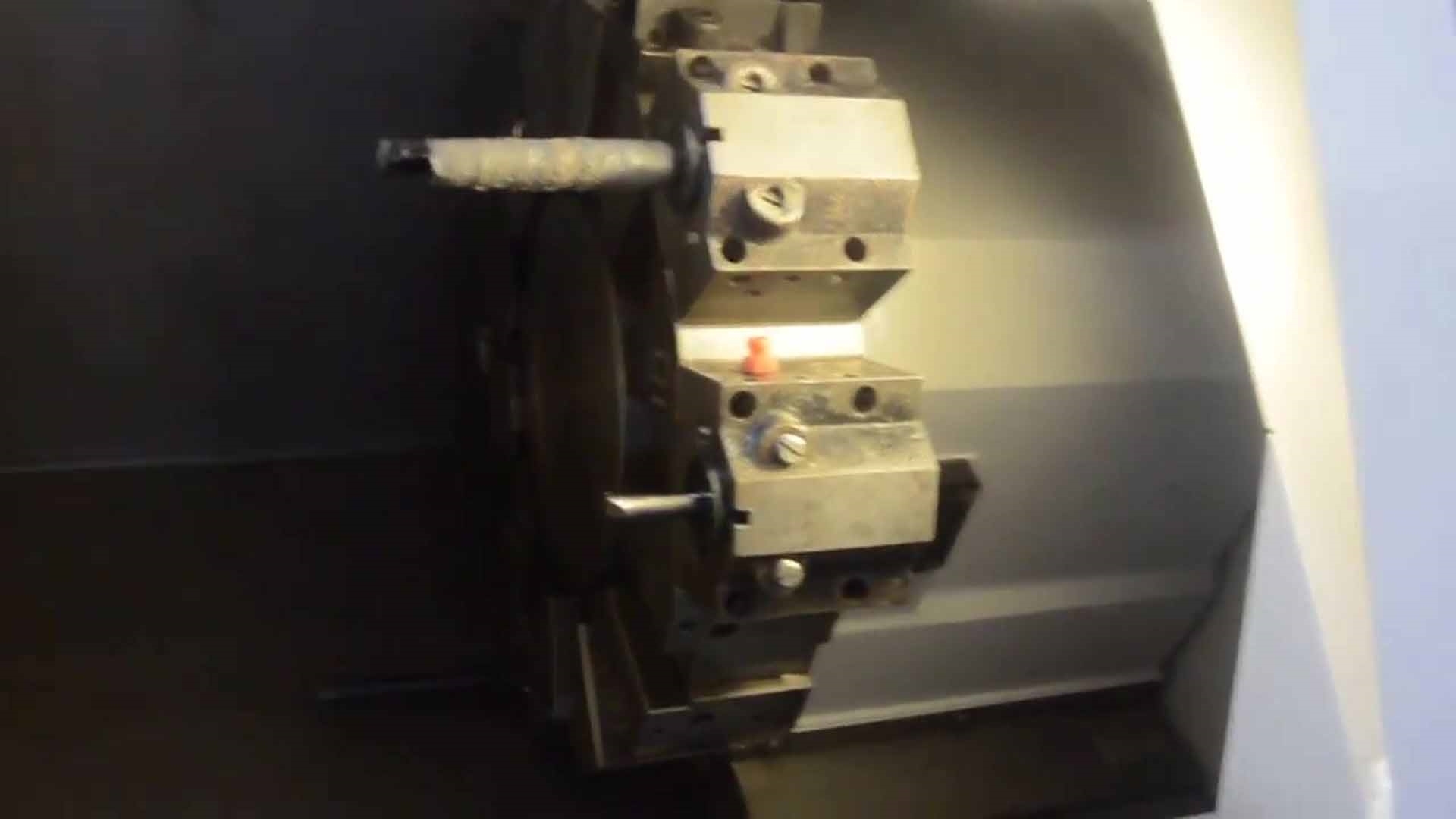

Turret position: 12

X-Axis travel: 9.05"

Y-Axis travel: 22.63"

Collect closer chuck

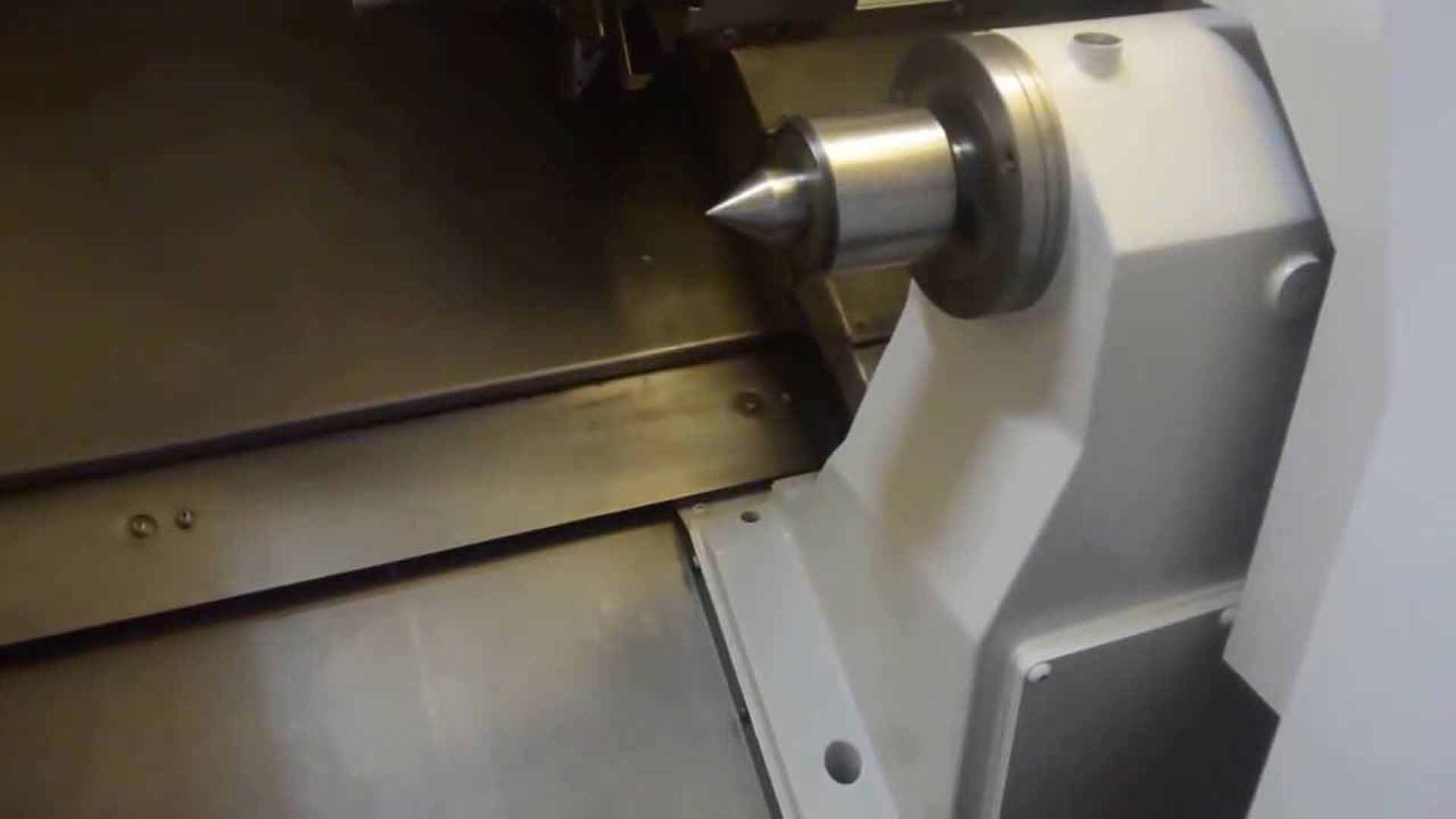

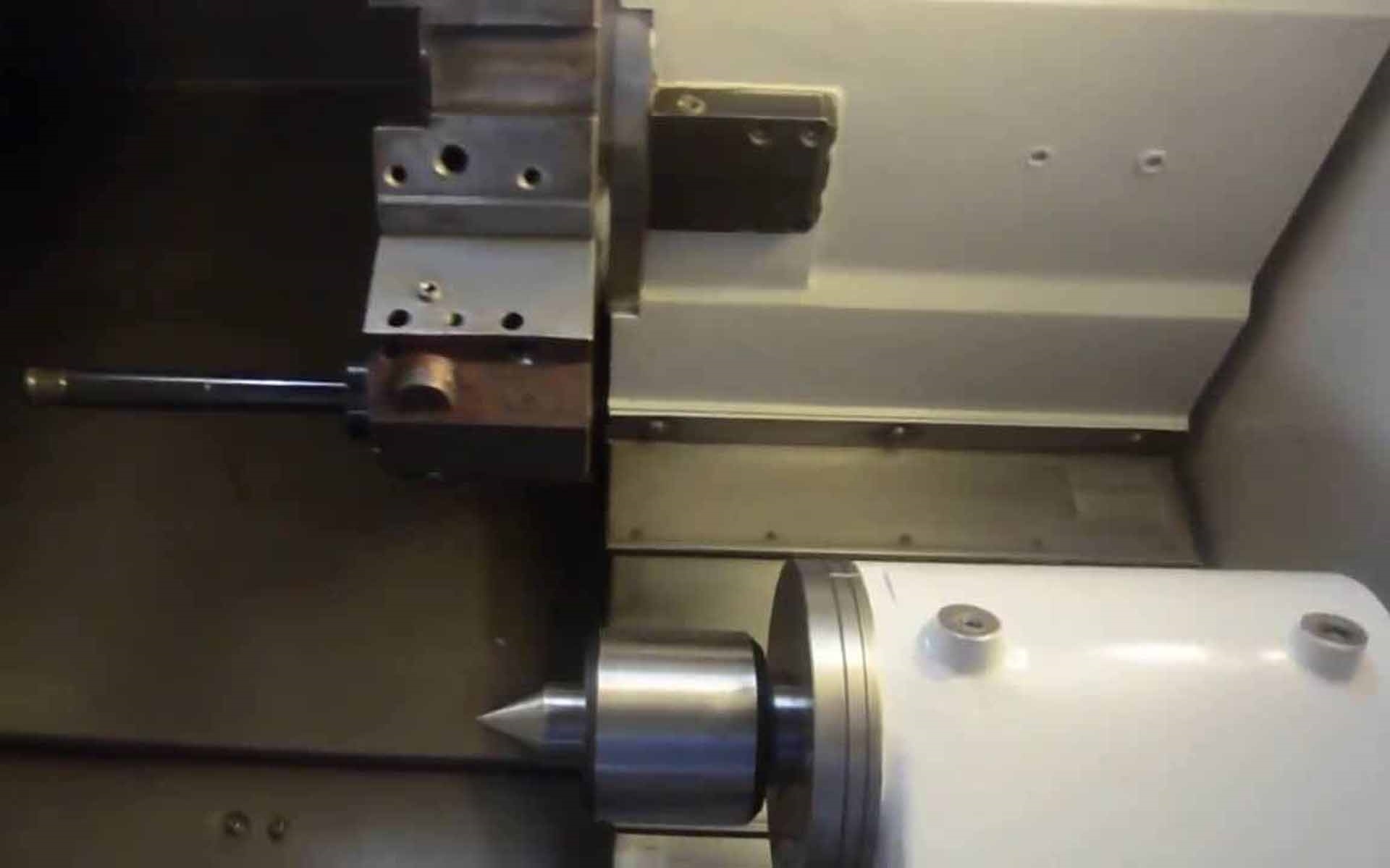

Tail stock / Chip conveyor

Parts catcher

Tool pre-setter

2008 vintage.

MAZAK Quick Turn Nexus 250-II is a CNC (Computer Numerical Control) machine tool made by MAZAK Corporation that is mainly used for the manufacturing of various components such as those for engines, automobiles, airframes, military hardware, and medical instruments. It has an iron-frame structure and offers superior cutting performance with total accuracy. Equipped with the latest technology such as MAZAK MIDAC control and automatic tool changers, Quick Turn Nexus 250-II is a highly reliable piece of machinery that can greatly improve the efficiency of metalworking operations. MAZAK Quick Turn Nexus 250-II is powered by a single-spindle and is capable of cutting a variety of materials, including steel, aluminum, and stainless steel. It has a medium-duty spindle motor that generates up to 125 hp (93 kW) for superior cutting power, and is capable of rotating at speeds up to 6,000 RPM. The spindle has been designed to reduce vibration during operation and includes a large range of cutting tool options, ensuring high quality results. The tool changer is a 12-position belt type automatic tool holder that allows for the quick and easy switching between different types of tools during production. The CNC control installed on Quick Turn Nexus 250-II is MAZAK MIDAC, a fully programmable unit that is highly customizable and easy to use. It supports a range of interpolation methods (including G codes) as well as cutter radius compensation for improved accuracy. The Mazac MIDAC also includes an auto-signal monitoring circuit that detects errors related to tool wear and other maintenance issues, allowing the operator to quickly address them and continue production. MAZAK Quick Turn Nexus 250-II is equipped with a 40-station automatic tool changer, offering ultimate flexibility in production. With an average cycle time of 1.25 seconds per tool, it can easily switch between different tools during a run, eliminating downtime and increasing productivity. For safety purposes, the CNC control has been fitted with several failsafe features including a safety switch and an over-travel alarm, allowing the user to be protected from potential dangers during operation. The unit also has a generous range of other features, including a Fanuc loader for easy tool data exchange, a 60-degree headstock tilt for increased production options, and a soft-start feature that automatically controls spindle speed during startup. All these features come together to make Quick Turn Nexus 250-II a reliable, reliable CNC machine that can be used for a range of metalworking operations.

There are no reviews yet