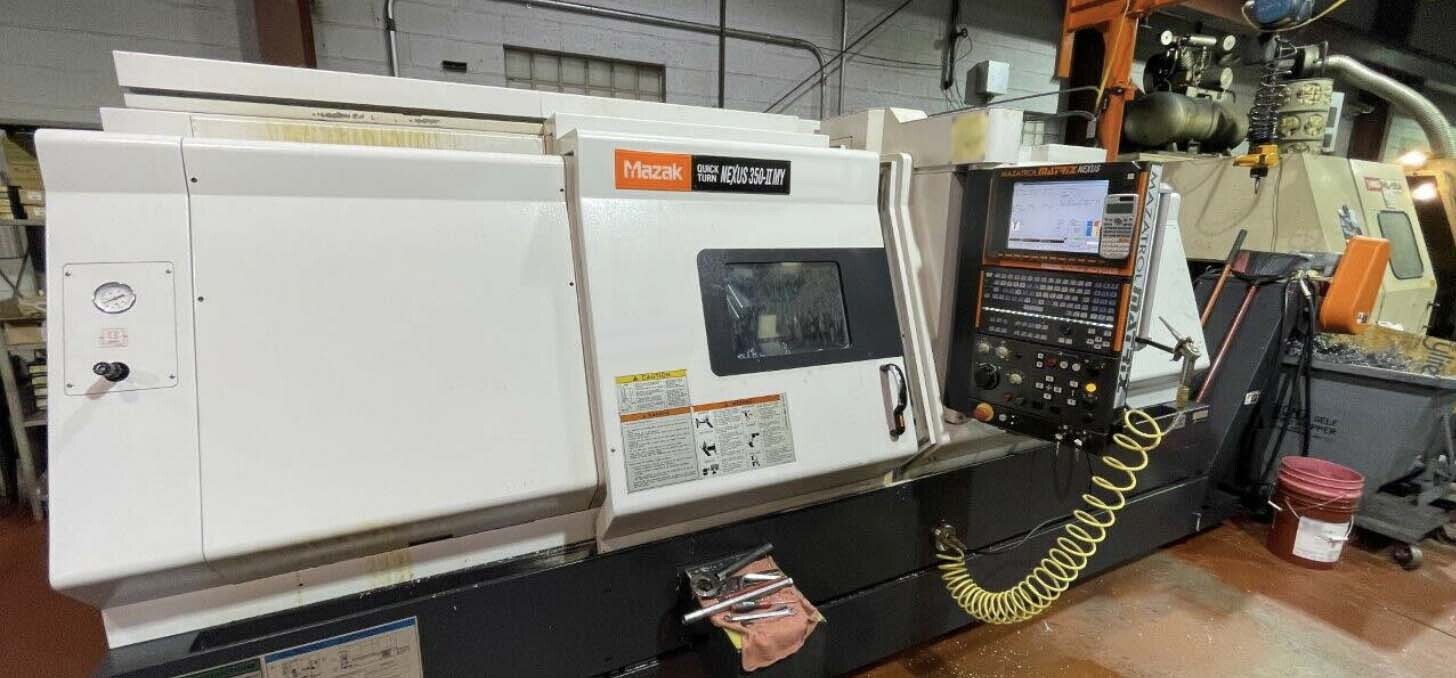

Used MAZAK Quick Turn Nexus 350-II MY #293605916 for sale

URL successfully copied!

Tap to zoom

ID: 293605916

Vintage: 2007

CNC Lathe

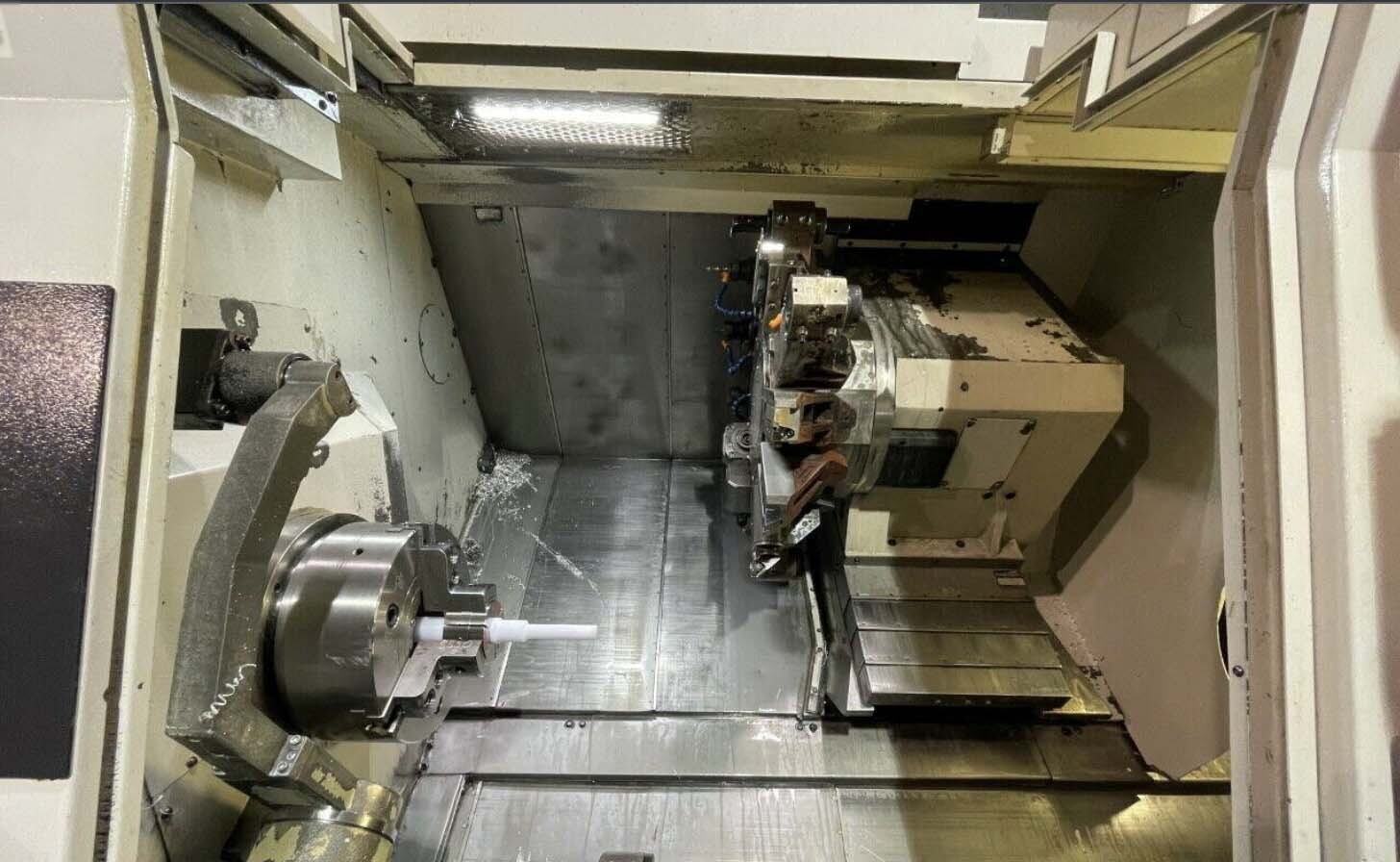

Swing, 29.5"

4-Axis

Chuck, 12"

Bar capacity: 4"

Power: 40 HP

Spindle speed: 3,300 RPM

Turning diameter: 16.5"

Tailstock

Y-Axis milling

(4) Tool holders

Chip conveyer

Centers bed, 60"

MAZATROL Matrix CNC Control

Spindle nose 1, 2: A2 - 11

Spindle bore diameter 1, 2: 4.5"

X-Axis travel X1, X2, X3: 11"

Z-Axis travel Z1, Z2, Z3: 26.75"

Y-Axis travel Y1, Y2, Y3: 6"

C-Axis indexing 1, 2: .0001

Turret tool positions 1, 2, 3: 12

Turret rotary tool speeds 1, 2, 3: 4,000 RPM

Turret rotary tool horse power 1, 2, 3: 10 HP

Tailstock quill diameter: 3.94"

Tailstock taper: MT 5

Tailstock travel: 25.5"

Rapid traverse rates:

X1, X2, X3: 1,181 IPM

Z1, Z2, Z3: 1,299 IPM

Y1, Y2, Y3: 59 IPM

2007 vintage.

MAZAK Quick Turn Nexus 350-II MY is a compact,highly productive vertical turning machine tool designed for precision and versatility in machining operations. This machine combines a high level of performance, accuracy, and efficiencies with enhanced operational convenience to deliver ideal results in productions requiring high-precision parts and short batch production. The machine features a rigid constitution And a high feed rate for maximum accuracy and productivity. The main spindle is directly driven by a servo motor to offer powerful machining capabilities even at high speeds. Quick Turn Nexus 350-II MY is equipped with an integrated C-axis control and two C-axis synchronous simultaneous servo motors to expand the operations and give more control over the machining process. These motors control spindle speed, feed rates and other machining operations. The machine offers 30 tool stations, boasting a high speed indexing time of 1.3 seconds. The turret is designed with a 12-position disk-type tool magazine to increase productivity and reduce setups, while a tool-eye is positioned above each tool station for easy setup verification. High pressure coolant is also employed for safer and efficient machining operations. MAZAK Quick Turn Nexus 350-II has an ergonomically designed control panel with graphic displays that allows for ease of use. The machine utilizes the FANUC 18i-TB CNC control, offering advanced functions and capabilities such as sub-program storage, machining cycle selection and data input. Tool path verification and "look ahead" functions provide a safe and efficient programming environment. MAZAK Quick Turn Nexus 350-II MY is constructed with a cast iron construction and its design ensures high stability and accuracy. Its X, Z and C-axis positioning ability provide optimal control and access to give a variety of part sizes, shapes, and operations. The larger turning diameter of 813 mm over its bed make it the ideal choice for large diameters machining operations. Overall, Quick Turn Nexus 350-II MY machine tool is a powerful and very versatile solution for precision and complex machining operations. It provides extensive operational performance, maximum accuracy and reliability, reducing machining time and promoting efficiency. It is the perfect tool to help companies increase productivity, meet tight deadlines and increase profitability.

There are no reviews yet