Used MAZAK Quick Turn Universal 350 #9212095 for sale

URL successfully copied!

Tap to zoom

ID: 9212095

Vintage: 2015

CNC Lathe

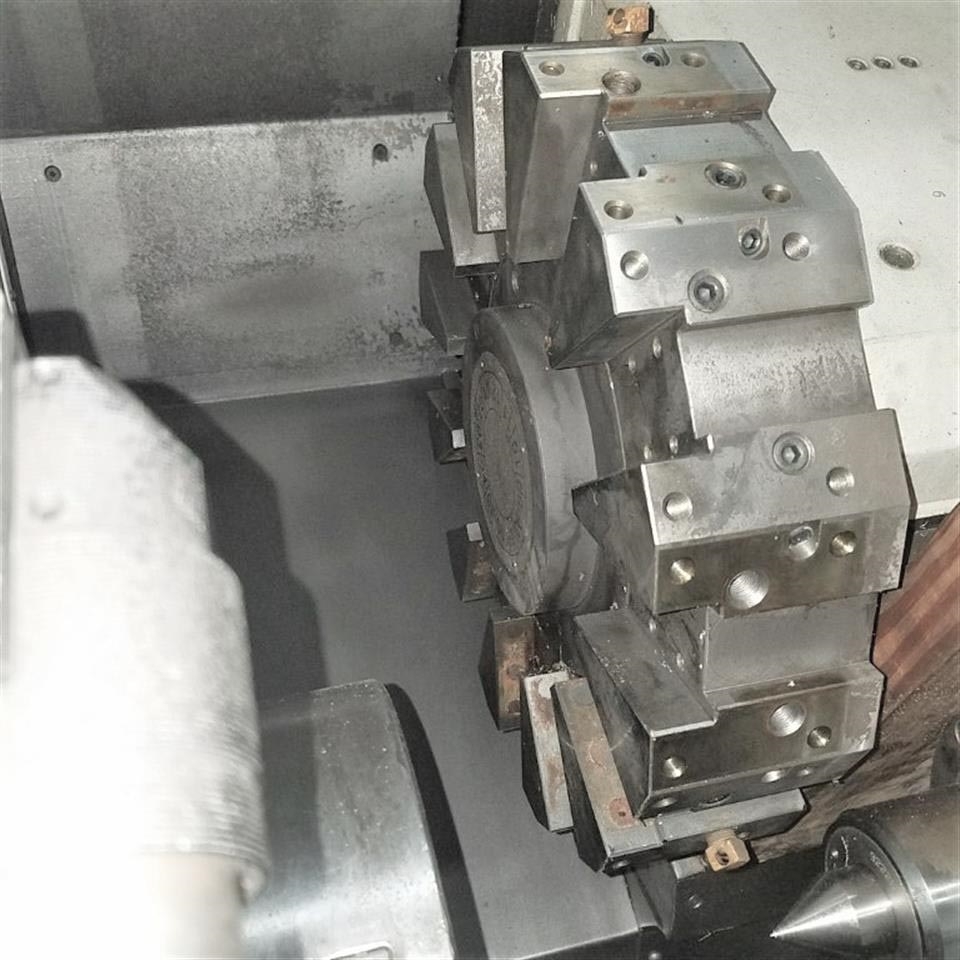

Chuck size: 10" Hydraulic

Maximum swing: 27.4"

Maximum cutting diameter: 16.25"

Maximum machining length: 25"

Maximum bar capacity: 3.15"

X-Axis travel: 8.5"

Z-Axis travel: 25"

Spindle nose: 2"-8"

Spindle bore: 3.58"

Spindle speed: 3500 RPM

Spindle motor: 20 HP

Number of turret positions: 12

Rapid traverse rates: 1181 IPM

Tail stock center / Tail body travel: MT 5 / 22.125"

Includes:

(13) Jaw thru hole hydraulic chucks: 10"

Tool presetter

Chip conveyor

Tail stock

Coolant tank and coolant pump

Tool path solid model

DNC: RS-232C

Floppy disk drive: 3.5"

IC Memory card interface

(2) PCMCIA Interfaces

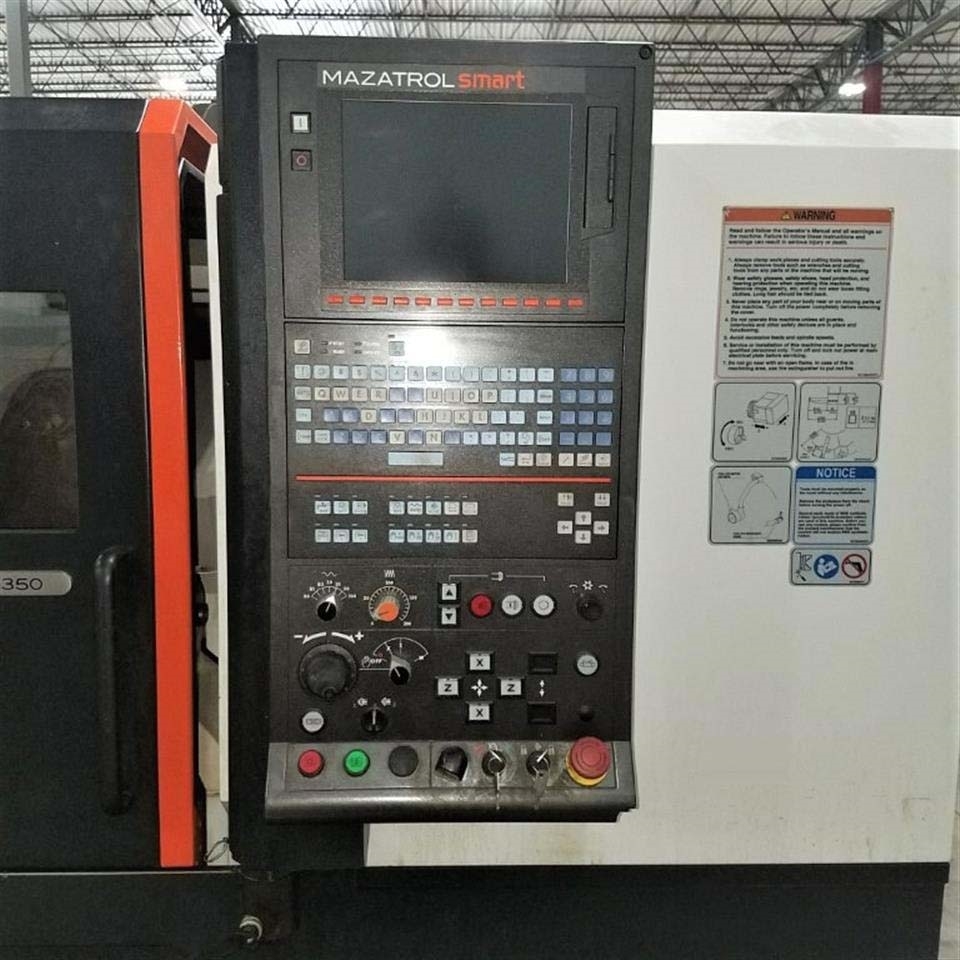

Color monitor: 10.4"

Manuals

Tooling

Multi-tap transformer

Hydraulic pressure interlock

Door interlock

Integral spindle motor design

2015 vintage.

MAZAK Quick Turn Universal 350 (QTU 350) is a machine tool designed to quickly and accurately produce a variety of complex parts. With its powerful three-axis CNC (Computer Numerical Control) equipment and highly accurate spindle, the QTU 350 is capable of machining many different materials with extreme precision and accuracy. The machine has a number of powerful features such as a high-speed live tooling spindle, programmable tool changing, and a 15 inch color LCD touch-screen monitor. The machine is fitted with MAZAK Millstar CNC control system which is designed to simplify the programming of complex parts. The Millstar is easy to learn and use, and has a number of advanced features such as advanced tool motion control for higher speeds, collision avoidance and obstacle detection for safe operation, and an intelligent machine interface. Combined with the wheel-based rapid traverse of the X, Y and Z axis, the QTU 350 can quickly and accurately produce a variety of complex parts. The spindle on the QTU 350 can achieve speeds of up to 10,000 RPM, allowing for a wide range of cutting operations and tight tolerances. The spindle is also equipped with a powerful pre-bearing motor that can increase thermally induced repeatability errors by up to 10 times. This allows for faster parts production and better part accuracy. The QTU 350 also offers a range of optional accessories, to meet the specific machining requirements of different customers. An automatic tool changer with up to 40 tools can be used, as well as a tool breakage detection unit, a parts catcher and a parts conveyer. Further options such as a Y-axis table, a KIT-CAM interface, and a stabilizer machine are also available. With its powerful features, Quick Turn Universal 350 is a highly advanced machine tool that can produce complex parts to tight tolerances. The machine's CNC tool and powerful spindle make for efficient part production, and the range of optional accessories make it suitable for a variety of manufacturing requirements.

There are no reviews yet