Used MAZAK VCN 515C-II #9194970 for sale

URL successfully copied!

Tap to zoom

ID: 9194970

Vintage: 2007

CNC Vertical machine center

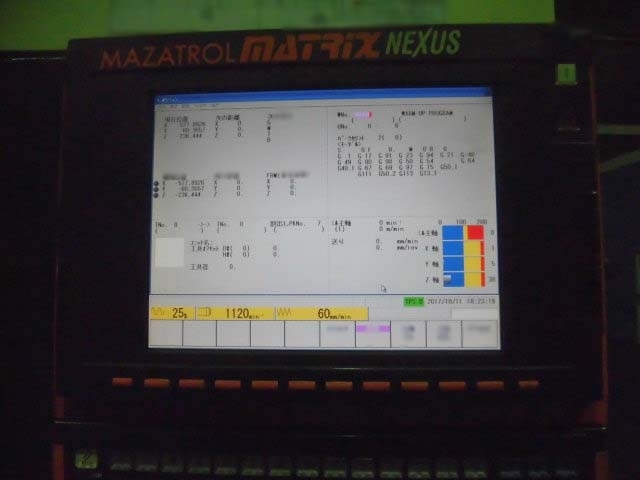

Control: MAZATROL Matrix Nexus

Table size: 1300 x 550 mm

Stroke (X,Y,Z): 1050 x 510 x 560 mm

Spindle speed: 8000 RPM

BT50

ATC: 24

2007 vintage.

MAZAK VCN 515C-II is a state-of-the-art high-precision 5-axis vertical machining center designed and manufactured by MAZAK Corporation, a leading manufacturer of CNC machine tools. VCN 515C-II is a robust machine capable of consistently delivering high machining accuracy and precision on complex parts of aerospace, medical, and other industries. MAZAK VCN 515C-II has a rigid, Meehanite-cast base construction and minimal cross-sectional dimensions, which make it ideal for difficult-to-machine components. The spindle is PC core cooled and uses a double-row, preloaded angular contact bearing arrangement. This allows for superior accuracy when cutting at high speeds and enables consistent and reliable machining results. VCN 515C-II uses MAZAK Smooth G- Technology for 5-axis simultaneous motion control. In addition to the standard pitch, yaw, and roll, Smooth G- enabled cutting offers a fully adjustable interpolated sixth-axis of motion. This results in higher work envelope flexibility and smoother cutting action across different cutting angles and at various points along the material. MAZAK VCN 515C-II is equipped with an automatic tool changer with a maximum capacity of 80 tools. By connecting to a commonly used tool magazine system, up to 630 tools can be used for maximum efficiency and flexible automation. The construction of the tool changer is designed to provide less vibration and fast reaction times, regardless of the tool's weight, shape, and size. This gives the user increased accuracy and improved production cycles. VCN 515C-II has a generous working envelope, allowing the use of larger sizes, longer cutting tools, and different cutting angles to accommodate difficult-to-machine parts. It is equipped with a motorized spindle and direct drive table, both of which provide high-precision, high-speed machining performance. The spindle is also servo controlled for a constant spindle speed throughout the cutting process, even on thin material. MAZAK VCN 515C-II is highly efficient, featuring MAZAK Intelligent Edge simultaneous 5-axis machining technology, a reliable and diversified rotary control system, and advanced spindle control. With all of these features, VCN 515C-II is specialized for complex workpieces requiring precise and reliable machining. Furthermore, it can be tailored for various applications by adding optional features such as a high-pressure coolant unit for improved machining accuracy and/or machine polishing/deburring options for highly cosmetic surfaces. MAZAK VCN 515C-II is an ideal machine tool for producing complex parts with high precision and accuracy. Its robust construction and advanced cutting technologies offer a reliable, efficient, and diversified machining experience. With its combination of features, VCN 515C-II is ideal for applications in aerospace, medical, and other industries.

There are no reviews yet