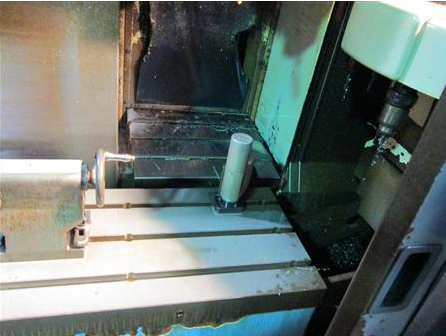

Used MAZAK VTC 16 B #9083434 for sale

URL successfully copied!

Tap to zoom

ID: 9083434

Vintage: 1995

Vertical machining center

Mazatrol M32B

Specifications

Table Size: 57.48" x 16.1"

Table Load Capacity: 1600 lbs

Table Top to Spindle Nose: 4.3" - 24.4 "

X-Axis Travel: 44.09"

Y-Axis Travel: 16.08"

Z-Axis Travel: 20.08"

Spindle Taper: CAT 40

Spindle Speed: 40 - 7000 RPM

Spindle Motor: 15 HP

Tool Magazine Capacity: 24 Position ATC

Maximum Tool Diameter: 4.3"

Rapid Traverse X, Y, Z: 670/787/590 IPM

Machine Dimensions : 119"x97.63"x106"

Machine Weight: 11,660 lbs

Equiped with:

Troyke 4th Axis Rotary Table & Tailstock

Chip Conveyor

Automatic Tool Length Measurement

Adaptive Feedrate Control

Tool Life Monitoring

Tool Breakage Detection

Rigid Tapping

Multi-Tap Transformer

All Available Manuals

RS-232C for DNC Interface

Tool Changer Motor needs repair or replaced

1995 vintage.

MAZAK VTC 16 B is an efficient and reliable bridge-style vertical machining center designed specifically for milling large parts and heavy components in multiple operations. VTC 16 B provides high productivity and superior surface finishes for a variety of aviation, automotive, medical, and electronics applications. This machine tool has a large working area, with a maximum workpiece size of 2.0m x 1.8m. MAZAK VTC 16 B bridge-style vertical machining center features a cast-iron base and rigid design to ensure accuracy and stability. It is powered by a highly reliable MAZAK CNC control system, with intuitive programming software, ensuring ease of operation and increased productivity. VTC 16 B incorporates an innovative 42-kW spindle that offers high torque, durability, and superior cutting speed. This spindle reaches a maximum speed of 15,000 RPM and delivers an impressive cutting capability while maintaining remarkable precision in the workpiece. To efficiently store and access cutting tools, the machine is equipped with a 180-tool magazine, with up to 61,800lbs of tool storage capacity. MAZAK VTC 16 B is also fitted with an exclusive Twin Table System that maximizes production throughput. This horizontally arranged table design accommodates two pallets at the same time, allowing easy access for manual or automated loading systems. High-speed positioning is enabled by the machine's high acceleration and deceleration rates, offering maximum efficiency for complex machining operations. The thermal displacement of VTC 16 B is minimized thanks to its built-in thermal displacement sensor. This ensures high accuracy, even with different thermal environments. To further improve this machine's capability, an option for enhanced accuracy is also available. This machine has an advanced safety system to ensure operator safety and increase productivity. Its powerful automated functions, space-saving designs, and environmental adaptability make it an ideal choice for a wide range of milling applications, even those with extreme accuracy and reliability requirements. MAZAK VTC 16 B machine tool is your ultimate solution for all industrial milling needs.

There are no reviews yet